Metal Hose Assembly

Price:

Get Latest Price

In Stock

Product Overview

Key Features

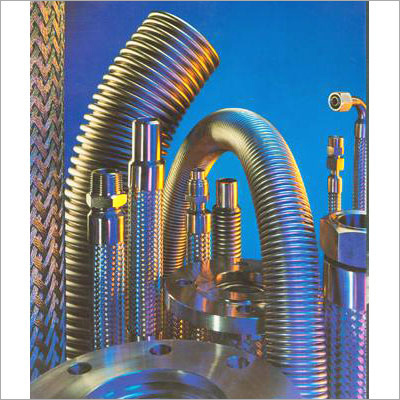

Metal Hose Assemblies Our experts are engaged in offering a wide range of hose assembly that

are fabricated by using high grade raw material and are known for their

durability, performance and anti corrosive properties.l Hmbly: Terminology:

Specification

According to which the hose assembly is manufactured

Annular Core

Designed so that each convolution is a complete circle or ring

Close Pitch

Less spacing between the corrugations, thereby giving longest fatigue life and minimum bend radius

Braid

Woven wire sheath placed over hose which prevents elongation of the hose under internal pressure

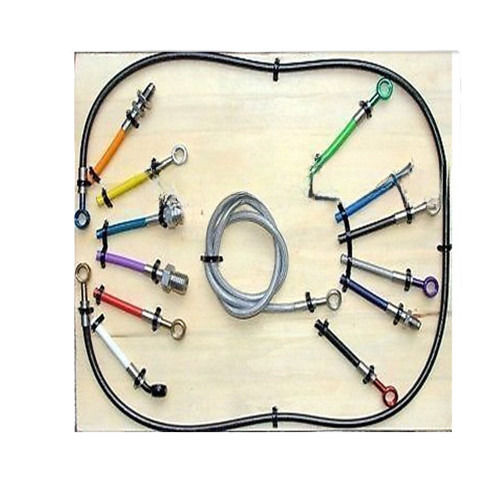

Fittings

Parts attached to the ends of metal hose so that it can be connected to other components like flanges, unions, stub ends, nipples

Constant flexing bend radius

The minimum radius to which a hose can be repeatedly bent and render satisfactory flexure life

Operating conditions

Pressure, Temperature, Media, Motion and application involved

Max. Test Pressure

Max. Pressure for testing purpose. Based on 150% of the max. working / design pressure

Media

Material conveyed by the hose assemblies such as chemicals, gases, liquids

Working temperature

Temperature which hose is subjected to during operation

Corrosion Data

Contact KFI or any NACE standards

Rated Burst Pressure

The pressure at which the hose assembly can be expected to fail

Safety Factor

Difference between working pressure and rated burst pressure

Construction:

Specification

BS 6501

Close Pitch Annular Core

SS 304, SS 304L, SS 321, SS 316, SS 316L

Braid

SS 304, SS 316

Size Range

1/4" ID to 8" ID

Temperature

(-)200

to 800C for SS 321 / SS 316 / SS 316L

(-)200 to 400C for SS 304 / SS 304LTechnical Data:

Size(ID)

OD (Single Braid)

Single Braid(bar g)

Double Braid (bar g)

Bend Radius (mm) (Single Braid)

Inch

mm

mm

W.P.

T.P.

W.P.

T.P.

Static

Dynamic

1/4

6.40

12.20

100

150

100

225

45

100

3/8

9.50

15.80

90

135

90

203

50

150

1/2

12.70

19.00

80

120

80

180

65

200

3/4

19.05

26.30

64

96

64

144

70

203

1

25.40

33.80

50

75

50

13

104

229

1 1/4

31.75

42.00

40

60

40

90

117

267

1 1/2

38.10

51.60

30

45

30

68

152

292

2

50.80

61.70

28

42

28

63

160

318

2 1/2

63.50

77.00

24

36

24

54

175

508

3

76.20

91.00

18

27

18

41

231

610

4

101.60

117.50

16

24

16

36

250

750

5

127.00

149.00

12

18

12

27

318

900

6

152.40

178.00

10

15

10

22.5

353

1050

8

203.20

228.00

8

12

8

18

456

1180

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

10

Establishment

2004

Working Days

Monday To Sunday

GST NO

27AAIFK0153E1ZO

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAIFK0153E1ZO

Dombivli, Maharashtra

Partner

Mr. Mahendra Patel

Address

Plot No. X-18/7 Subodhi Building, Mamta Hospital Road, Midc Phase Ii, Dombivli East, Dombivli, Maharashtra, 421201, India

metal hose assemblies in Dombivli

Report incorrect details