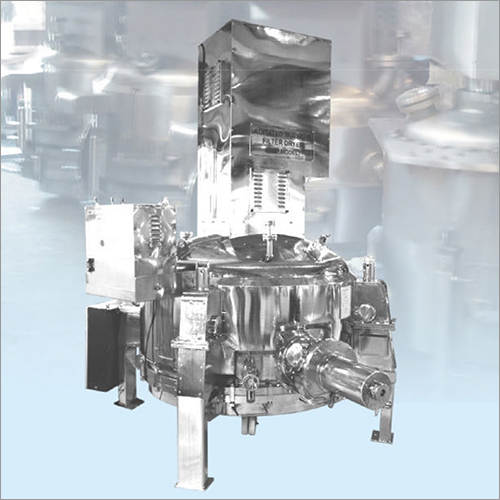

Stainless Steel Metal Agitated Nutsche Filter Or Dryer

Price Trend: 5000-100000 USD / Set

Get Latest Price

Minimum Order Quantity :

1 Set

In Stock

Product Specifications

| Weight | Customised Kilograms (kg) |

| Usage | Pharma, Food, Chemicals & Other |

| Height | Customised Inch (in) |

| Size | Customised |

| Width | Customised Inch (in) |

| Length | Customised Inch (in) |

| Color | Silver |

| Power | Customised Volt (v) |

| Material | Stainless Steel |

| Voltage | Customised Volt (v) |

| Warranty | 1.5 Year |

| FOB Port | Nhava seva Mumbai |

| Payment Terms | Telegraphic Transfer (T/T) |

| Supply Ability | 15 Per Month |

| Delivery Time | 70 Days |

| Packaging Details | Export Worthy Packing |

| Main Export Market(s) | Australia, Central America, North America, South America, Eastern Europe, Middle East, Africa, Western Europe, Asia |

| Main Domestic Market | All India |

Product Overview

Key Features

Ideal equipment /system for hazardous/toxic material

Various multiple processes as above can be carried in single equipment an added advantage

Removable filter bottom with conventional clamps or bayonet locking system.

Heated/unheated agitator, agitator with two or three arms, with simultaneous axial and radial agitator movements for efficient mixing and agitating as well as for the smoothing of the cake.

Large heating area resulting in an outstanding heat transfer rate by heating the vessel walls, the vessel bottom as well as the agitator blades.

Multiple washing of filter cake feasible with different solvents/ washing fluids possible with Lesser liquid consumption

All Dryer Internals, product process area is in 316 / 316L, stainless steel construction, Mirror polish.

Sturdy welded external shell reinforcement ensures maximum operating protection and Dependability under full vacuum operation.

Heated Limpet Coiled/ Jacket in combination with vacuum atmosphere ensures complete Vaporization of moisture and drying of the product.

Validation ports and nitrogen purge nozzles provided.

Vapor condensation unit along with a receiver for solvent recovery.

CIP (Cleaning In Place) system can be provided.

PLC-based automation of process batch control, with printable option.

Full validation services available including DQ, IQ/OQ, FAT / SAT protocols.

cGMP construction for Pharmaceutical Models.

compliance with ASME pressure vessel code, Section VIII

Kilolab Model to Production Models available

Capacity ranges from 50 Liters to 10000 Liters

OPTIONS

Heel removal systems, CIP, SIP

PLC controlled system

Online Sampling Valve/ port

MOC

All Stainless Steel/ Hastelloy construction with Contacts / vapor parts in 304/ 316 / 316L built to custom requirement.

All Process contact surfaces finished with corrosion-resistant Fluro-polymer coatings such as Ptfe, Halar, etc.

Company Details

Incepted in the year 1979, Shiv Shakti has been at the forefront of manufacturing & exporting of Process Equipment, engineering system for Pharmaceutical, Bulk Drugs, chemical, & allied industries. We specialize in Centrifuge Machines, Rotocone Vacuum Dryers, Fluid Bed Dryers, Vacuum Tray Dryers, Octagonal Blender. Apart from manufacturing, the group is also involved in sourcing, inspection, and supply of a variety of process equipment for Pharmaceutical, Bulk Drugs, Chemicals Agrochemical, & allied industries to meet the specific requirements of customers.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

15

Establishment

1979

Working Days

Monday To Sunday

GST NO

27AABCS1164M1Z7

Certification

ISO 9001:2000

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AABCS1164M1Z7

Mumbai, Maharashtra

Director - Exports

Mr Laxmi Vishwakarma

Address

407, Shivam Chambers, Next to Sahara, S.V. Road, Mumbai, Maharashtra, 400062, India

agitated nutsche filter dryer in Mumbai

Report incorrect details