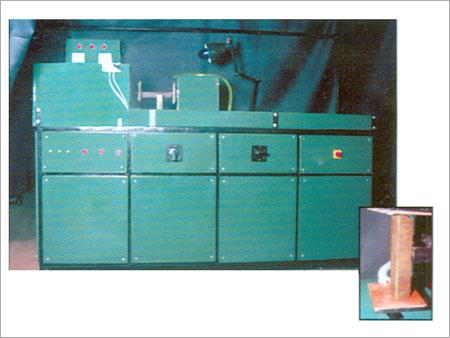

Magna Testing G. Iii Magnetic Testing Unit

Price:

Get Latest Price

In Stock

Product Specifications

| Output current | 0-3000 amperes |

| Coil diameter | 350 mm |

| Component length | 1500 mm |

| Tank capacity | 30 liters |

| Electrical supply | 400/440V |

| Air supply | 3-6 atmospheres |

| Dimensions | 2000x610x2000 mm |

| Features | Defect detection, High amperage, Low voltage, Easy to use, Cost effective, Fast testing, Reliable results, Improved efficiency |

Product Overview

Key Features

G. 111 MAGNETIC TESTING UNIT

Specification

| Output current | 0 to 3000 amperes A.C. Continuously variable over the whole range |

| Coil | Internal diameter 350 mm consisting of 5 complete turns |

| Components | Maximum length 1500 mm |

| Tank Capacity | Approximately 30 litres. |

| Electrical Supply | 400/440 volts 50 Hz, Single phase peak current approx 36 amps (for duration of maximum value current shot only) |

| Air Supply Requirements Frame Dimensions | 3 to 6 atmospheres (40 to 90 psi.) 2000 long 610 mm deep 2000 mm overall height. including hood 1000 mm bench height Approximate weight: 330 Kg. |

Company Details

Focusing on a customer-centric approach, Ved Electrical & Electronics has a pan-India presence and caters to a huge consumer base throughout the country. Buy Voltage Stabilizers in bulk from Ved Electrical & Electronics at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

15

Establishment

1995

Working Days

Monday To Sunday

Related Products

More Product From This seller

Seller Details

Ludhiana, Punjab

Managing Partner

Mr. Ved Kumar V

Address

Plot No. F-33, Phase-7, Focal Point, Ludhiana, Punjab, 141010, India

Voltage Stabilizers in Ludhiana

Report incorrect details