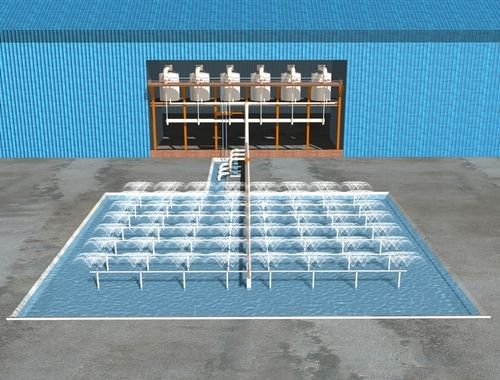

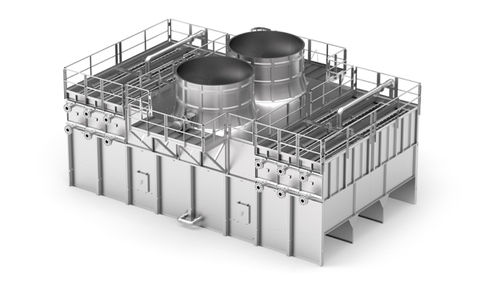

Low Temperature Evaporative Module

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless steel |

| Dimensions | Variable |

| Capacity | Customizable |

| Wetting rate | 3-5 L/h-cm |

| Pressure | Low exhaust |

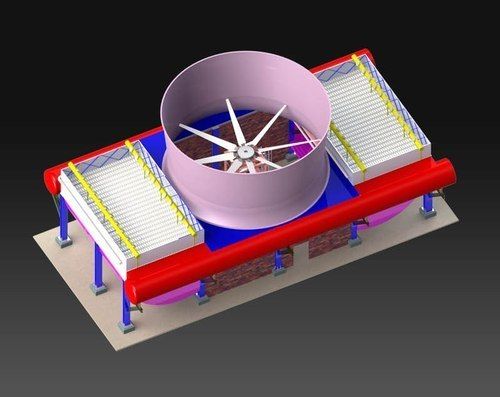

| Power | Turbine driven |

| Efficiency | High |

| Features | Improved quality, Increased capacity, Reduced losses, Lower costs, Patented tech |

Product Overview

Key Features

oImproves final product quality due to low exhaust pressure at evaporator station.

oIncrease plant capacity utilization.

oIncrease imbibition water.

oIncrease power generation from turbine.

oReduce steam use in juice heating.

oReduce process sugar losses.

oReduce steam and juice flash heat losses.

oMinimize colour in juices.

oReduce entrainment losses in pans.

oReduce inversion at high temperature.

oReduce power losses in turbine.

oReduce complicated bleeding schemes.

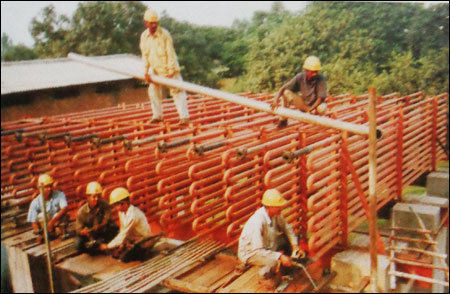

oLow operating cost due to very low wetting rate i.e. in the range of 3-5 L/h-cm.

oPATENTED TECHNOLOGY *

Using this technology the following equipment that gets eliminated from the existing process are Exhaust/ Vapour Condensate Heat Recovery, Insulation of Evaporator and Heaters, Semi-Kestners, Falling Film and Vapour Cells, Entire Juice Heater, Chain driven by Steam and Condensate Flashing above 100A C.

Company Details

Focusing on a customer-centric approach, Spray Engineering Devices Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Get Heat Exchangers from Spray Engineering Devices Ltd. at Trade India quality-assured services.

Business Type

Manufacturer, Service Provider, Supplier

Establishment

1991

Working Days

Monday To Sunday

GST NO

03AAICS5252M1Z5

Related Products

More Product From This seller

Seller Details

GST - 03AAICS5252M1Z5

Mohali, Punjab

Proprietor

Mr. Amit Parmar

Address

House No-C-82, Industrial Area, Phase-7, Near Aircel Building, Mohali, Punjab, 160055, India

Heat Exchangers in Mohali

Report incorrect details