Lean Phase Pneumatic Conveying System - High Volume Transfer Up To 50 Tph | Low Pressure Requirement, Fluidizing Technique, Pressure & Vacuum Options

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Capacity | 50 Tph |

| Conveying Length | 300 Mt |

| Air Ratio | Less Than 10 |

| Blower Type | Positive Displacement |

| Feeder Type | Rotary Valve |

| Density | <800Kg/M3 |

| Features | Low Pressure, High Volume, High Velocity, Fluidizing Technique, Positive Displacement, Non-Abrasive, Non-Fragile |

Product Overview

Key Features

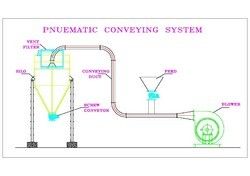

Lean Phase Pneumatic Conveying System

We provide our clients with lean phase pneumatic conveying system, which is widely appreciated all over for its low pressure requirement. Two pivotal features of the lean phase conveying design amalgamate for offering a fluidizing conveying technique that in turn is known for reducing air pressure requirements. Lean phase pressure system makes use of low pressure, high volume (cfm) air / gas as the motive force for transferring powder or granular bulk solid through a pipeline at high velocity. We offer two types of lean phase conveying systems, viz. Pressure type & vacuum type.

Salient Features:

- Makes use of low pressure, high volume gas & high velocity to fluidize for transferring powder or granular bulk solids up to capacity 50tph

- Solid to air ratio ( kg solid / kg air) less than 10

- For lean phase pressure system conveying length is up to 300mt. Approx.

- For lean phase vacuum system conveying length is up to 50mt approx.

- Systems utilize a positive displacement blower to create the requisite motive force

- Rotary valve & venturi can be made use of as feeder in lean phase conveying system

- Lean phase systems are extensively used on non-abrasive, non-fragile and light density (typical <800kg/m3) material

- Du

- Chemicals

- Petrochemicals

- Pharmaceutical

- Distillery / brewery

- Paint & pigment handling

- Food industry

- Power

- Steel

- Cement

- Mineral pro st free operation

- Chemicals

- Petrochemicals

- Pharmaceutical

- Distillery / brewery

- Paint & pigment handling

- Food industry

- Power

- Steel

- Cement

- Mineral Processing

Company Details

We feel obliged to introduce our ambitious venture RAJDEEP ENGG. SYSTEMS (PUNE) PVT. LTD. which take care of attached product range as per requirement of its esteemed clients at global level. Since inception, in 2001, RAJDEEP has been venturing into Industrial Air pollution control Systems and Pneumatic Conveying Systems & making utmost efforts to make the best deal available to its clients. We have been an established company with an excellent track record for the best customer satisfaction and never compromised on the quality and the services provided to the customer. We believe in keeping the customers happy and providing them with products at a very competent price. We have an excellent staffs who will guide you with their best ideas by keeping in constant touch with your company and informing you about new innovation and technical up-gradation time to time. We are specialized in new systems supply as well as REVAMPING , UPGRADATION, CAPACITY ENHANCEMENT related projects. We are specialized in Turnkey project management and executed numerous projects in following sectors. - Food Industry - Pharmaceutical Industry - Chemical Industry - Petrochemical Industry - Steel and Non Ferrous Industry - Cement Industry - Paint & Pigment Industry - Fertilizer Industry - Distillery and Brewery and many more . . . . . . . We provide our clients with an unmatched range of : => Air Pollution Control Systems => Dust Collection Systems / Bag Filters => Pneumatic Conveying Systems : Lean phase and dense phase conveying systems => Material Handling Systems => Dust Extraction Systems => Auto Weighing & Batching System => Bag Filters => Scrubbers => Rotary Air Lock Valves => Screw Conveyors => Bin Activators => Cyclones => Silos

Business Type

Exporter, Manufacturer, Supplier

Employee Count

30

Establishment

2000

Working Days

Monday To Sunday

GST NO

27AADCR0029E1ZT

Certification

ISO 9001:2008 & ISO 9001:2000

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AADCR0029E1ZT

Pune, Maharashtra

Sr. Manager - Marketing

Mr. Sachin Pawar

Members since

3 Years

Address

"Address " - Plot No-225/5, Pune Solapur Road, Pawar Complex, Gadital, Pune, Maharashtra, 411028, India

pneumatic conveying system in Pune

Report incorrect details