Kemklin-109(rust Remover)

Price:

Get Latest Price

In Stock

Product Specifications

| Color | Blue |

| Composition | Acid blend |

| Odor | Pungent |

| Foaming | Nil |

| Solubility | Good |

| PH | Acidic |

| Toxicity | Nil |

| Features | Rust removal, Effective cleaning, Metal protection, Easy application, Fast acting, Safe handling, Cost effective |

Product Overview

Key Features

Kemklin-109(Rust Remover)

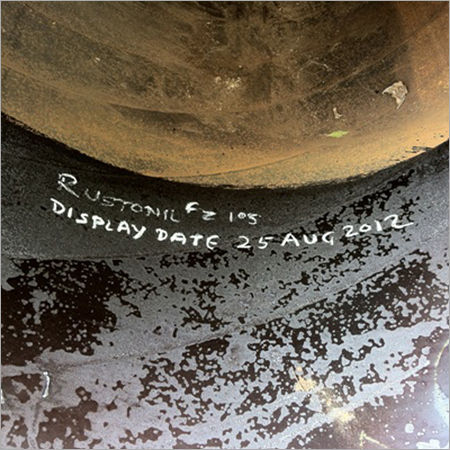

(Rust Remover By Spray Application)

Product Description

Kemklin-109 is specially formulated to remove mild rust from ferrous and non-ferrous metals effectively by spray process. Kemklin-109 (S) is purely based on phosphoric acid enriched with various types of solvents/surfactants and wetting agents, etc. Kemklin-109(s) attacks only on rust or scales and it does not attack on the base metal.

Product Specifications

| a. | Colour | Colourless Liquid |

| b. | Chemical Composition | Blend of different types of acids with inhibitors, and emulsifiers etc. |

| c. | Odour | Slightly Pungent |

| d. | Foaming Tendency | Nil |

| e | Reliability | Good |

| f. | Handling | Avoid Skin Contact |

| g | Solubility | Good |

| h. | pH | Acid Range |

| i. | Toxicity | Nil |

| j. | Flash Point | Nil |

| k. | Pollution Hazard | Moderate |

Product Operating Data

| Concentration | 10%V/V |

| Temperature | 35-45oC |

| Spray Time | 120-240 sec. |

| Spray Pressure | 1-1.2kg/cm2 |

| Pointage | 8-10 m |

Product Operating Procedure

Fill the tank with water and add: Kemklin-109(s) at the rate of 10% and mixed it thoroughly and raise the temperature to 35-45oC. prior to dip in Kemklin-109(c) bath, components should be free from oil, grease, strength and spray time of Kemklin-109(s) can be increased if the components are heavily contaminated with heavy rust. After processing in Kemklin-109(s), the work should be rinsed thoroughly in clean water and subjected to phosphating bath. Kemklin-109(S) bath can be maintained by simple titration and does not require any skilled labour or any chemical knowledge. Bath should always be maintained at operating level with recommended concentration freshly prepared bath acts rapidly but the action gradually decreases due to the accumulation of iron concentration in the bath. Increase the temperature at this stage accelerates the derusting action, but the temperature should be controlled and it should not go above 55oC.

Product Application Equipments

Kemklin-109(S) tanks should be lead lined, rubber lined, glass fibre, rigid polythene, stainless steel tanks made out of 18 gauge sheets preferred. Steam coil or nozzles should be 316 SS.

Testing and Control Procedure

Pipette out 10 ml. of bath solution and further diluted with 90 ml of distilled water.

Pipette out 10 ml. Diluted solution into the conical flask and add 2 to 4 drops of indicator methyl orange.

Titrate against N/10 sodium hydroxide solution.

The colour changes from orange red to orange yellow.

If the bath pointage goes down from the recommended level, Add: 8.33 ltrs. Kemklin-109(S) for increasing one pointage in 1000 ltrs. bath.

Iron Concentration

Pipette out 10 ml. of bath solution and add 10 ml. of 50% concentrated H2SO4. Mix it thoroughly, titrate this against N/10. Kmno4 solution till the colour changes to light pink stable for 15 seconds. % of iron in the bath is calculated as 0.056 x titrate reading. Maximum permissible limits of Iron concentration in Kemklin-103 bath is 7%.

Chemical Replenishment

The bath should be discarded when of concentrated solution and increase in the temperature does not show faster derusting action and powder deposits appear on the surface of the metal. Iron contamination should be more than 7%.

Safety Measures

Kemklin-109 is an acidic liquid material, and while handling proper care should be taken. Protect eyes and skin by means of goggles, aprons, gloves, etc. If it comes in contact with skin and eyes, wash thoroughly with a flush of water and get medical advice.

General Information

Heavy Rust Removal: Excellent

Paint Adhesion: Good

Gloss Retention: Good.

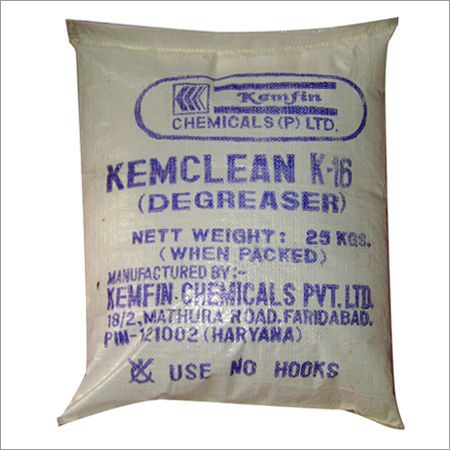

Company Details

Focusing on a customer-centric approach, KEMFIN CHEMICALS (P) LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Corrosion Protection Materials in bulk from KEMFIN CHEMICALS (P) LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

31

Certification

ISO 9002

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Ballabgarh, Haryana

Director

Mr. Lokesh Bhalla

Address

41 KM, Khandawali Road, Ballabgarh, Haryana, 121004, India

rust remover spray in Ballabgarh

Report incorrect details