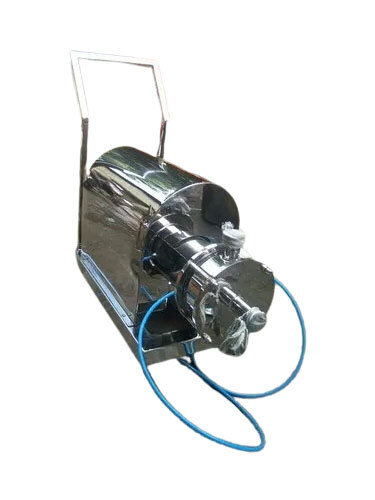

Inline Homogeniser - High Shear Agitation System , Versatile Mixing For Liquids And Solids

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless Steel |

| Power | 10-50 HP |

| Capacity | 100-1000 L/hr |

| Pressure | 50-300 bar |

| Dimensions | Variable |

| Weight | 100-500 kg |

| Usage | Liquid and solid mixing, emulsifying, and homogenizing in various industries. |

| Features | High Shear, Inline Mixing, Efficient Dispersion, Emulsification, Versatile Use |

Product Overview

Key Features

Inline Homogeniser Specification:

In

Inline agitation system, the possibility of materials - Liquid or Solid

passing through it, without subjected to intense hydraulic and

mechanical shear actions is zero. Here suction pipe (inlet pipe) is

centrally mounted & outlet is radially mounted, therefore it is

physically impossible for any material to pass from inlet to outlet

without exposed to agitation.

The stator which

surrounds rotor is available with various type of opening i.e. round,

square, rectangular & with perforation also so that all the

critical demand of Mixing, Emulsifying, Disintegration & Dispersion

of solids, suspension can be met out by same equipment.

The

machine is versatile & has completely revolutionized the

traditional mixing techniques. Here close tolerance of rotor with the

stator produces high hydraulic shearing & mechanical action that

ensures that material entrapped between rotor & stator is subjected

to tremendous shearing actions each minute.

Fluid Mixing Mechanisms:

In terms of mechanical mixing mechanisms, a number of actions are

employed by different types of mixers to create different effects for

particular process results. For distributive action, swirl created by

rotating parts causes laminar thinning of the material interfaces,

thereby increasing volumetric combination of the materials. A repeated

cutting and folding action of the mixture also increases the

distribution of different material components. The effectiveness and

efficiency of a mixer in distributive mixing is therefore a function of

how the machine interacts with the fluid in a geometric sense.

Conversely,

the effectiveness and efficiency of a mixer in dispersive mixing is a

function of how the machine interacts with the fluid in a stressing

sense. For most materials, the higher the stress, the smaller the

resulting particles or droplets in the mixture. However, another very

important consideration is the uniformity of the stress field. Without

a reasonable uniformity, it is impossible to guarantee that the same

stress is applied to all parts of the fluid. This would result in a

wide range of final droplet or particle sizes rather than a narrow

range obtained with uniform stressing. One or more of the three primary

stressing mechanisms are used in most fluid mixers.These mechanisms are:

- Shear

- Extension

- Impact

Inline Mixers:

Usually

called "high-shear mixers", are the most common form of

Dispersing/Homogenising/ Emulsifying mixer. By placing a form of

closely-fitting shroud around a high speed impeller, it is possible to

create a shearing action between the blades and stator shroud. As

material is centrifugally pumped through the mixing head, some of it

will see this high shear zone and experience shear stressing that

results in dispersive mixing. Where small or uniform dispersions are

required, material must be cycled through the head many times to ensure

statistically that all of the material has passed through the high

shear zone at leastonce.

Pumping Actions:

Because of indigenous design & rotor operating at very high speed

in close clearance with stator draws the material in & imparts

mechanical & shearing actions. Inline Homogenizer facilitates high

volume, non positive action which is sufficient to transfer the

material without any supplementary pumps but in some cases because of

high viscosity, vertical lift or length of pipe line , the flow rate

may come down below the anticipated value, In that case it is

supplemented by an auxiliary pump installed in the system which pumps

the liquid without reducing the homogenising/emulsifying efficiency of

the system.

End Connection:

The

inlet & outlet are normally fitted with. DIN, Tri Clover/ Sanitary

Screw fittings but other Modes of fittings can be provided on request.

Sealing:

Single mechanical seal with Carbon, silicon carbonized phase

combination is provided. Special single or double sealing is also

available for conditions & process which demand it eg. Latex ,

Abrasive solids.

Application Of Inline Homogeniser/Emulsifier

Inline emulsifier is successfully used for the following processes:

Recirculatory Processing:

There

are certain processes which demand higher degree of homogenization,

dispersion, communication & but to attain that level, single passage

of material through Inline is not sufficient to reach that degree, in

that situation, it is more useful to pass the product several times

through the same machine by means of recirculation. The above process

is normally adopted in producing emulsion of Oil & Water. Oil,

which is lighter than water is charged in the holding vessel &

water is added into the pipe line between vessel outlet valve &

Inlet of Inline Emulsifier. This mix is immediately sucked into the

head of emulsifier & there mixing/ emulsification/ homogenization

takes place. This mix is then sent into the vessel. This process is

repeated till achievement of perfect emulsion. Where viscosity is very

high or vessel size is large, it is recommended to go for Batch type

mixer along with Inline Mixer.

Premix Process:

In

this process, all ingredient are mixed in a holding vessel with some

agitator & a single passage through the inline smoothens the lumps

and homogenize a suspension or emulsion. Inline Mixer is currently in

use in the industry listed below & this gives a new horizon for

this exceptional machine to validate its results.

- Creams

- Dairy & Confectionery Items

- Beverage & Brewery

- Paper Coating

- Pharmaceuticals

- Pesticides & Insecticides

- Paints

- Natural Herbal Dye

Capacities Available:

3 Hp models to 25 Hp models

Company Details

Focusing on a customer-centric approach, RAVI INDUSTRIES has a pan-India presence and caters to a huge consumer base throughout the country. Buy Pharmaceutical Machinery in bulk from RAVI INDUSTRIES at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

17

Establishment

1985

Working Days

Monday To Sunday

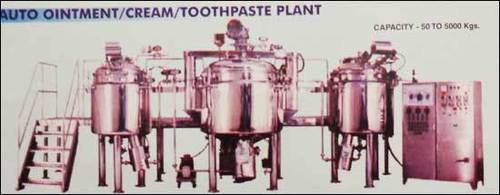

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Mumbai, Maharashtra

Managing Partner

Mr R K Panchal

Address

B/17&19, Adke Compound, Suryanagar, L.B.S. Marg, Vikhroli (W), Mumbai, Maharashtra, 400083, India

inline homogeniser mixer in Mumbai

Report incorrect details