Durable Industrial Tmt Equipment

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Power | Variable |

| Capacity | Variable |

| Weight | Variable |

| Efficiency | High |

| Accuracy | High |

| Features | High Durability, Long Lifespan, Corrosion Resistant, Precise Cutting, Efficient Quenching, Customizable Design, High Meterage, Increased Toughness |

Product Overview

Key Features

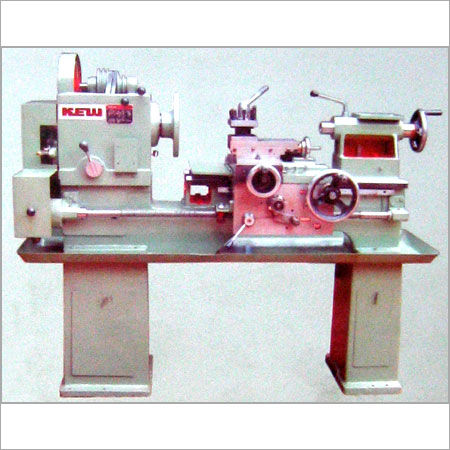

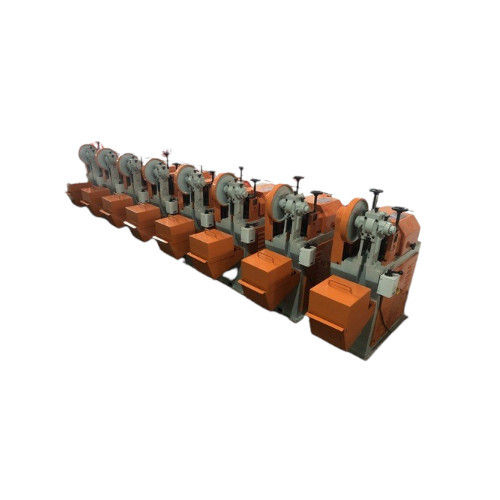

Aided by innovative techniques and modern machinery, we are able to offer Industrial TMT Equipment to our clients. These products are used for making various types of bars and rods. Industrial TMT Equipment find application in many engineering and processing industries. Known in the market for their less wear and tear, longer service life, corrosion resistance and immaculate performance, these products have a high demand in the market. Keeping in mind the diverse requirements of the clients, we can modify the design and size of Industrial TMT Equipment.

Quenching System:

Quenching is a rapid method of cooling certain workpiece to get its material properties. It provides a narrow window of time to cool that prevent the material from the phase of transformation. Its reaction is both kinetically accessible and thermodynamically favorable. Also, this process minimizes the crystallinity and simultaneously increases the toughness of the metal.

The Quenching Box is designed for systematic and effective Quenching System, which provide the Thermo Mechanical Treatment. It assists in keeping the metal corrosion resistant and increases its mechanical properties such as Elongation, Bending, Yield Stress, Tensile Strength, etc. It assists in delivering Thermo Mechanical Treatment plus bar with high meterage at per unit weight.

The system is supported by the following accessories:

Direct Drive Shear

High Pressure Injectors & Strippers

Instrumentation Support

Pinch Rolls

Quenching Box

Shears:

We are well equipped to develop the highly accurate and extremely durable range of Flying Shears. The machine is subject to customization for its best use in the industry. The Flying Shears offered by us find application for cutting purpose of bars. They are praised all across the country for its excellent performance and optimum quality.

Our range of Shears encompasses:

Cold Bar Shear

Continuous Shear

Crank Type Start Stop Flying Shear

Crop And Cobble Shear

Start Stop Flying Shear

Pinch Roll & Tail Breaker:

There are two rolls in Pinch Roll Assembly, which are either supported by bearings on both ends or through a cantilevers type via pinion stands. The pinch roll pulls the material such as strips, hot billet, sheets or bars, which has left the stand and pushed into the next stand such as processing equipment or quenching box.

And, the other material offered by us is Tail Breaker, which is basically a pinch roll that efficiently reduces the bar speed at the time it leaves the stand. This process ensures that the rolling bar stops within the cooling bed length.

| Quick Buyer Details | |

| Product Name | Industrial TMT Equipment |

| Product Code | IIMTE |

| Model Number | AR IIMTE |

| Brand Name | A. R. ENGINEERING |

| Product Type | Automatic |

| Business Type | Exporter , Manufacturer |

| Verified Supplier | Trust Stamp |

| Memberships | Okhla Industrial Estate Manufacturers Association |

| Export Markets | Worldwide |

| FOB Price | Sent by mail |

| Minimum Order Quantity | As per requirement |

| Place of Origin | New Delhi, India |

| Payment Terms | Cash in advance, before shipment, pre-authorized payment, credit card, debit card, net banking |

| Production Type | Automatic |

| Features & Technical Parameters for Industrial TMT Equipment | |

| Rolling Type | Hot rolling |

| Making way | Fully automatic |

| Color | Multiple option, Customized |

| Keywords | TMT Equipment, TMT Equipment Manufacturer, TMT Equipment Exporter, Industrial TMT Equipment |

| Features |

|

| Technical Parameters |

|

| Packaging & Delivery | |

| Packaging Detail: | Plywood case or nude package |

| Delivery Detail: | Timely delivery |

Company Details

Focusing on a customer-centric approach, A. R. ENGINEERING WORKS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Machineries in bulk from A. R. ENGINEERING WORKS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

160

Establishment

1985

Working Days

Monday To Sunday

Related Products

More Product From This seller

Seller Details

New Delhi, Delhi

Accepts only Foreign inquiries

Mr. Anil Khanna

Address

22, Okhla Industrial Estate, Phase-III, New Delhi, Delhi, 110020, India

Report incorrect details