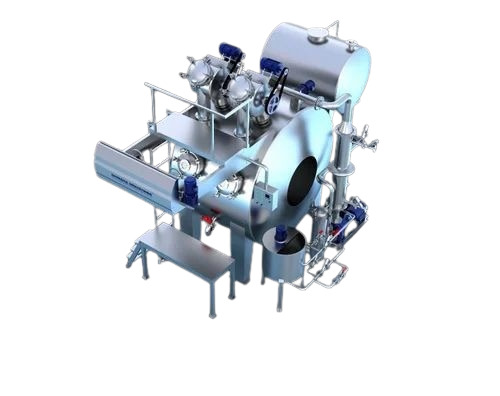

Industrial Hthp Vertical Filament Yarn Dyeing Machines

Price:

Get Latest Price

In Stock

Product Specifications

| Capacity | 5-1500 Kg |

| Pressure | 5.0 Kg/Cm2 |

| Material | Stainless Steel |

| Dimensions | Variable |

| Heating | High-Temp |

| Motor | High Efficiency |

| Controls | Digital |

| Features | Energy Saving, Water Saving, Chemical Saving, Improved Quality, Faster Payback, Sustainable Dyeing, High Efficiency, Even Dyeing |

| Payment Terms | Others |

| Main Domestic Market | All India |

Product Overview

Key Features

The Hthp Vertical Cone Dyeing Machine is a high-temperature, high-pressure dyeing machine that is ideal for use with synthetic fibers yarn zipper narrow tape losse fiber etc. The machine uses a round-shaped dyeing chamber that allows for even dye distribution and efficient heat transfer. The machine is also equipped with a number of safety features, including a pressure relief valve and an emergency stop button

Main advantages are:

Possibility to dye ratio from 1:3.5 using in to out single circulation with material not fully covered.

Reduce consumption of chemicals, dyes, water and steam due to low ratio facility.

Reduce power consumption of main pump because pipes are designed to avoid losses of pressure so that main pump is exploited in the best way. High efficiency motor and inverter reduces power consumption as well. Possibility to dye also in traditional way: air pad, material fully covered and flow circulation in to out and out to in directions.

SMDY ENERGY SAVING

The consumption of water, chemicals, electrical energy, thermal energy and the wasted water are important cost factors in every dye house. With this HTHP Horizontal Yarn Narrow Tape & Zipper Dyeing Machine all these factors are dramatically reduced, measured and controlled. Right-first-time in dyeing is now assured by lower differences inside-outside the packages, while savings of electric energy, water, chemicals, steam and compressed air will bring extremely fast payback times over the initial investment cost.

New SMDY sizes are from 5 kg to 1500 kg. This machine with this particular pump and inversion group allows to treat polyester textured high density till 0,5 Kg/l as well as very soft material like silk 0,3 kg/l density in order to process every kind of material you can have in your dye house.

70% savings on electric energy

30% savings on water, chemicals and utilities

Improved yarn dyeing quality

Faster payback times

Sustainable yarn dyeing

This is our new SMDY yarn dyeing machine! Yarn dyeing, reinvented! 70% savings on electric energy 30% savings on water, chemicals and utilities Improved yarn dyeing quality Faster payback times Sustainable yarn dyeing.

SMDY FEATURES:

a c Standard design and manufacturing features:

a c Nominal loading capacities from 5 to 1500 kg.

a c Pressure rating of 5.0 kg/cm2, up to 160A C tempera-

ture, temperature lock at 140C.

a c Construction in AISI 316 stainless steel, for all the

part in contact with dyeing liqu-or.

a c Water protected motors (IEC Standards I).

a c Waterproof electrical equipment

a c Three-level safety systems..

a c Heat exchangers rated for 15.0 kg/cm2 operating

pre

Company Details

Established in 1967 under the leadership of Mr. Shri Ram Sharma , an Mechanical engineer with more than 3 decades of experience in the Textile and Apparel Manufacturing Industry, S M W India is dealing in textile machinery, as well as providing consulting services in the field. We strive to provide the best machines and deals to our clients, with unparalleled after sales services and support. Our skillful technicians are able to help clients in the installation, operating guidance and maintenance.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

12

Establishment

1967

Working Days

Monday To Sunday

GST NO

07AACFS6633B1ZH

Certification

iso 9001 - 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AACFS6633B1ZH

New Delhi, Delhi

Marketing Manager

Mr Jatin Sharma

Address

B-110, Phase - 1, Maya Puri Industrial Area, New Delhi, Delhi, 110064, India

Report incorrect details