Industrial Gear Couplings - Triple Crowned Teeth Design, High Quality Material, Enhanced Misalignment Tolerance, Exceptional Abrasion And Corrosion Resistance

Price:

Get Latest Price

In Stock

Product Specifications

| Material | NA |

| R.P.M. | 8000 |

| Bore Min | 10 |

| Bore Max | 40 |

| Torque Kg | 50 |

| H.P. capacity | 7 |

| Weight in Kg | 4.5 |

| Features | Solid structure, Accurate dimension, Fine finish, Abrasion resistance, Corrosion resistance |

Product Overview

Key Features

Industrial Gear Couplings:::::::::

An immaculate and long range of high quality Gear Couplings is offered by us at competitive as well as leading industry rates. The couplings are flawless and ideal to be used in different industries due to its attractive and beneficial features like solid structure, accurate dimension, fine finish, excellent abrasion & corrosion resistance etc. Furthermore, we offer them in different specifications including customization as per the requirements of the customers.

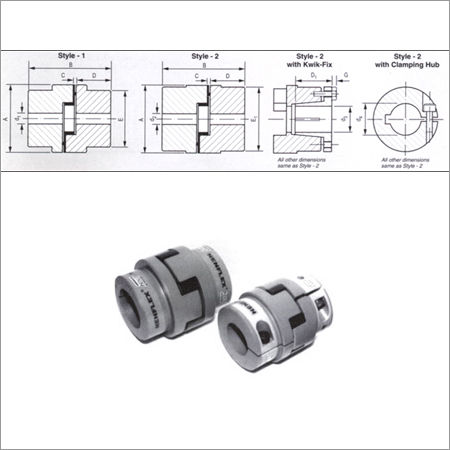

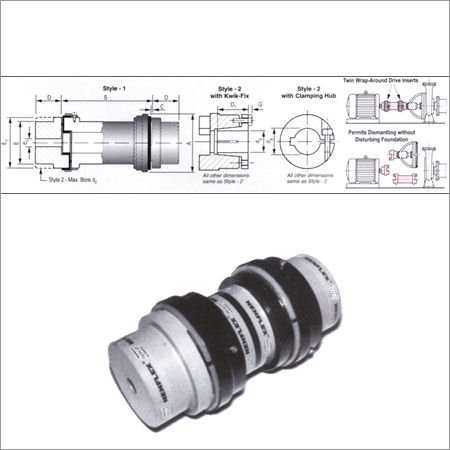

Nu-Teck manufactures straight tooth Gear Coupling and Tripple Crowned Teeth Gear Coupling.

Disadvantage in Straight Tooth Gear Couplings are

- Under the misalignment condition of two shafts of the equipments, the teeth contact in case of straight cut hub will be as minimum as shown in the fig No.1

- Under heavy loads the ends of the hub teeth will get damaged resulting in the excessive play between hub & sleeve and therefore the reduction in life of coupling

Nu-Teck Tripple Crowned Teeth Gear Coupling

- The triple crowned teeth hub is manufactured on a fully automatic hobbing machine with built in crowing attachment which is controlled by hydraulic & electronic systems.

- Under the misalignment condition of two shafts on the equipment, due to the curvature on teeth flank the contact area is much more and therefore, there is increase in life of coupling.

Misalignment Details: In case of straight tooth gear coupling the maximum allowable angular misalignment ( ) is 1.1/2 deg. and in case of NU-TECK Triple Crowned tooth Gear Coupling the misalignment is 3.1/2 deg.

| SERVICE FACTOR | PRIME MOVER | ||

| Driven Unit (Machinery) | Electric Motor or Steam Turbine | Geasoline or Diesel Engine 4 or more Cyl. | Gasoline or Diesel Engine more than 6 Cyl. |

| LIGHT | |||

| Uniform of Steady load never exceeding horse rating, infrequent starting : Agitators, Blowers, Can Filling Machines, Conveyors, Fans, Generators, Pumps, Steering Gear, Stokers. | 1.0 | 1.5 | 2.0 |

| MODERATE | |||

| Heavy inertia, moderate shock, frequent starting: peak loads do not exceed 125 percent average horsepower. Uneven load: Conveyorts, Feeders, Welding Laundry Washers, Mixers Paper Mills, Printing Presses, Screens, Textile Industry, Car Pullers. | 1.5 | 2.0 | 2.5 |

| HEAVY | |||

| Heavy shock conditions or frequent reverseing peak loads do not exceed 150 percent average horse power. Uneven load : Cranes & Hoists, Crushers, Dredges, Elevators, Hammer Mils, Lumber Industry. Machine Tools,, Metal Mills, Oil Industry, Rubber Industry Windlass. | 2.0 | 2.5 | 3.0 |

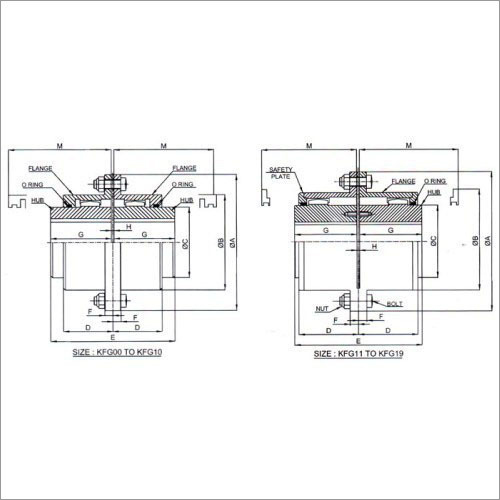

| COMMON FOR BOTH COUPLINGS | FULL FLEXIBLE TYPE | HALF FLEXIBLE TYPE | ||||||||||||||||||||

| NU-TECK G.C. No. | H.P. capacity AT 100 R.P.M. | Max. Torque Kg. M. | Max. R.P.M. | Bore Min. | A | C | D | F | M | G | H | Bore Max.a | J | B | WR2 Kgm2 | Wt in Kg | K | Q | Bore Max. | F1 | WR2 Kgm2 | Wt in Kg. |

| GC-100 | 7 | 50 | 8000 | 10 | 120 | 45 | 50 | 75 | 55 | 1.5 | 1.5 | 32 | 40 | 93 | 0.03 | 4.5 | 93 | 46.5 | 45 | 70 | 0.04 | 5 |

| GC-101 | 14 | 100 | 6300 | 20 | 170 | 55 | 65 | 110 | 65 | 2.5 | 17 | 45 | 49 | 115 | 0.14 | 11 | 115 | 57.5 | 60 | 85 | 0.15 | 11 |

| GC-102 | 35 | 250 | 5000 | 30 | 185 | 70 | 85 | 125 | 80 | 2.5 | 27 | 60 | 62 | 145 | 0.2 | 15 | 145 | 72.5 | 75 | 110 | 0.24 | 15 |

| GC-103 | 63 | 450 | 4000 | 40 | 220 | 85 | 105 | 150 | 105 | 2.5 | 20 | 75 | 78 | 175 | 0.48 | 25 | 175 | 87.5 | 90 | 130 | 0.51 | 20 |

| GC-104 | 119 | 850 | 3350 | 50 | 250 | 105 | 130 | 175 | 125 | 2.5 | 20 | 90 | 96 | 215 | 0.95 | 39 | 215 | 107.5 | 110 | 160 | 1 | 40 |

| GC-105 | 182 | 1300 | 2800 | 60 | 290 | 110 | 155 | 200 | 140 | 5 | 25 | 110 | 106 | 230 | 1.9 | 57 | 230 | 115 | 130 | 185 | 2 | 60 |

| GC-106 | 280 | 2000 | 2500 | 75 | 320 | 125 | 175 | 230 | 155 | 5 | 25 | 125 | 117 | 260 | 3 | 85 | 260 | 130 | 150 | 215 | 3.3 | 80 |

| GC-107 | 490 | 3500 | 2100 | 90 | 350 | 140 | 205 | 260 | 175 | 5 | 25 | 140 | 134 | 290 | 5.25 | 103 | 290 | 145 | 170 | 240 | 5.8 | 106 |

| GC-108 | 630 | 4500 | 1900 | 105 | 380 | 155 | 230 | 290 | 190 | 5 | 25 | 160 | 147 | 320 | 8.5 | 138 | 320 | 160 | 200 | 285 | 9.5 | 149 |

| GC-109 | 784 | 5600 | 1700 | 125 | 430 | 165 | 250 | 330 | 205 | 5 | 27 | 180 | 156 | 340 | 15 | 210 | 340 | 170 | 220 | 315 | 16.8 | 170 |

| GC-110 | 1148 | 8200 | 1400 | 140 | 490 | 180 | 310 | 390 | 220 | 5 | 27 | 220 | 171 | 370 | 30.5 | 277 | 370 | 185 | 260 | 370 | 35 | 264 |

| GC-111 | 1536 | 11000 | 1250 | 160 | 545 | 200 | 350 | 445 | 240 | 5 | 30 | 260 | 192 | 410 | 58 | 550 |

| |||||

| GC-112 | 2053 | 14700 | 1120 | 180 | 590 | 240 | 400 | 490 | 280 | 5 | 30 | 300 | 231 | 490 | 88 | 710 |

| |||||

| GC-113 | 2793 | 20000 | 1000 | 200 | 680 | 260 | 440 | 555 | 310 | 7.5 | 35 | 330 | 242 | 535 | 138 | 980 |

| |||||

| GC-114 | 3994 | 28600 | 900 | 220 | 730 | 280 | 500 | 610 | 330 | 7.5 | 35 | 370 | 266 | 575 | 291 | 1320 |

| |||||

| GC-115 | 4852 | 34750 | 800 | 250 | 780 | 320 | 540 | 660 | 370 | 7.5 | 35 | 410 | 305 | 655 | 353 | 1700 |

| |||||

| Coupling No. | Pilot Bore | Max. Bore | Max. Torque | Max. Speed | WT | H.P. Capacity at 100 RPM | Moment of Insersia Kgm2 | A | B | C | D | E | F | G | H | M |

| 114 | 220 | 370 | 28600 | 900 | 1320 | 3994 | 291 | 730 | 610 | 500 | 261 | 570 | 35 | 280 | 10 | 340 |

| 115 | 250 | 410 | 34750 | 800 | 1700 | 4852 | 353 | 780 | 660 | 540 | 305 | 655 | 35 | 320 | 15 | 385 |

| 115 M | 300 | 420 | 53570 | 750 | 2000 | 7480 | 500 | 825 | 690 | 558 | 315 | 690 | 45 | 335 | 20 | 400 |

| 116 | 300 | 455 | 60000 | 710 | 2550 | 8378 | 691 | 900 | 755 | 625 | 330 | 720 | 45 | 350 | 20 | 420 |

| 116 M | 330 | 480 | 72000 | 670 | 3100 | 10145 | 965 | 950 | 805 | 680 | 340 | 770 | 45 | 375 | 20 | 460 |

| 117 | 375 | 520 | 85350 | 630 | 3620 | 11917 | 1235 | 1000 |

| 720 | 380 | 820 | 45 | 400 | 20 | 490 |

NOTE

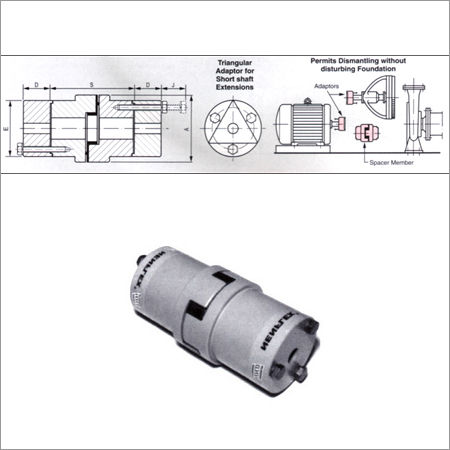

- Made to order / special Gear Coupling also can be manufactured

- Dynamic balancing & Heat Treatment will be done on request

- We also manufacture gear coupling with spacer & cordon shaft.

How to select the right Nuflex Gear Couplings ?

- Select the size Nuflex Coupling that will accomodate the diameter of the largest shaft. Usually this will determine the proper size Coupling for your condition.

- To make sure this Coupling has the required capacity:

- a) Check your application against the Service Factor Chart. Use the following formula to ontain HP per 100 RPM of your application

HP x Service Factor x 100 / RPM = HP / 100 RPM

Lubrication

Gear Couplings must be filled with proper grade of Grease or Oil while installation and periodically also. It is recommanded to use grease where the maximum temperature is within 80 oC and for temperature above 80 oC oil should be used. We suggest to use following grades of grease / Oil for a good performance.

For speed above 1500 RPM use oil SERVOMESH A-90 of Indian Oil Corporation having viscosity 91 C/S at 100 oC or of 324 = 35 cst/50 oC (43 o Engler / 50 oC) OR equivalant.

For lesser speeds use grease with high pressure additives like SERVOPLEX EP - 1 of Indian Oil Corpn. or SHELL ALVAMIA EP - 2 or lithium/sodium grease with EP / additives drop over 180 degree C grade of penetration.

Standard Specifications

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Company Details

Focusing on a customer-centric approach, DEL- JAYESS INDUSTRIAL SERVICES has a pan-India presence and caters to a huge consumer base throughout the country. Buy Coupling in bulk from DEL- JAYESS INDUSTRIAL SERVICES at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier, Trading Company

Establishment

1979

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Delhi, Delhi

Director

Mr. Gaurav Thapar

Address

5574 A, 17&18F, Kashiram Market, New Chandrawal, Opp. 18F Kamla Nagar, Delhi, Delhi, 110007, India

industrial gear coupling in Delhi

Report incorrect details