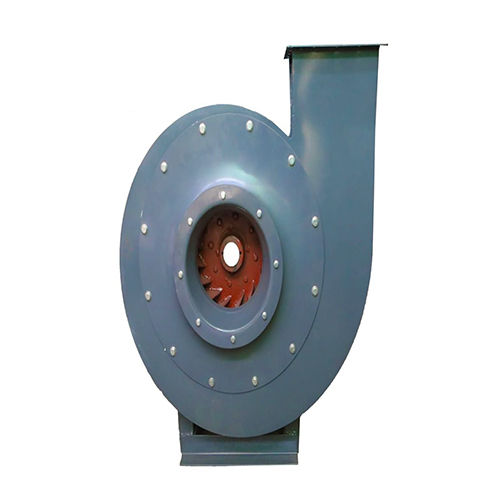

Industrial Air Pollution Control System - Material: Mild Steel

Price: 30000.00 INR / Unit

(30000.00 INR + 0% GST)

Get Latest Price

Minimum Pack Size :

1

In Stock

Product Specifications

| Usage & Applications | Industrial |

| Material | Mild steel |

| Cooling System | Water Cooling |

| Voltage | 220-440 Volt (v) |

| Warranty | Available |

| Payment Terms | Cash in Advance (CID), Cash Advance (CA) |

| Supply Ability | 10 Per Month |

| Delivery Time | 2-10 Days |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | as per customer requirement |

| Main Export Market(s) | Asia |

| Main Domestic Market | All India |

| Price | 30000.00 INR (Approx.) |

| Returnable | No |

| Price Type | fixed |

| Moq | 1 |

| Currency | INR |

| Stock Quantity | 5 |

| Unit Type | Piece/Pieces |

| Brand Name | Raj Enterprises |

| Product Unit | 1 Piece/Pieces |

| Mop | 1 |

| Minimum Order Quantity | 1 |

| Minimum Ordered Packs | 1 |

| GSTIN | 0% |

Product Overview

Key Features

Here's a short specification overview:

I. Types of Pollutants Controlled:

Particulate Matter (PM): Dust, smoke, fumes, mist, soot, aerosols (e.g., PM2.5, PM10).

Gaseous Pollutants:

Volatile Organic Compounds (VOCs): Hydrocarbons from solvents, paints, etc.

Nitrogen Oxides (NOx): From combustion processes.

Sulfur Oxides (SOx): Primarily sulfur dioxide (SO2) from fossil fuel combustion.

Hazardous Air Pollutants (HAPs): Specific toxic chemicals.

Acid Gases: HCl, HF, etc.

Odorous Compounds: Various organic and inorganic compounds causing unpleasant smells.

Other: Carbon Monoxide (CO), Carbon Dioxide (CO2) (though CO2 is primarily a greenhouse gas and its control often involves different strategies like carbon capture).

II. Key Technologies/Equipment:

For Particulate Matter (PM) Control:

Cyclones/Multi-cyclones: Use centrifugal force to remove larger particles.

Fabric Filters (Baghouses): Employ fabric bags to capture fine dust and particulate matter.

Electrostatic Precipitators (ESPs): Electrically charge particles and collect them on plates.

Wet Scrubbers: Use a liquid (water or chemical solution) to capture particulates and/or gases.

Mist Collectors: Collect liquid aerosols or mist.

For Gaseous Pollutant Control:

Scrubbers (Wet & Dry):

Wet Scrubbers: Use liquid to absorb or react with gaseous pollutants (e.g., for SOx, acid gases).

Dry Scrubbers: Use dry reagents (e.g., lime) to react with and neutralize acidic gases.

Oxidizers:

Thermal Oxidizers (Incinerators): High-temperature combustion to convert VOCs and HAPs into CO2 and H2O.

Regenerative Thermal Oxidizers (RTOs): Energy-efficient thermal oxidizers that recover heat.

Catalytic Oxidizers: Similar to thermal oxidizers but use a catalyst to promote oxidation at lower temperatures.

Adsorption Systems: Use solid adsorbents (e.g., activated carbon) to capture gases and VOCs.

Selective Catalytic Reduction (SCR) & Selective Non-Catalytic Reduction (SNCR): Used for NOx removal.

Biofilters: Use microorganisms to degrade organic pollutants, particularly effective for odor control and some VOCs.

III. Common Specifications/Design Considerations:

Pollutant Removal Efficiency: Typically expressed as a percentage (e.g., 90%, 99%, 99.99%). This is a critical performance indicator.

Gas Flow Rate/Capacity: Measured in cubic meters per hour (cmh) or cubic feet per minute (cfm), indicating the volume of gas the system can treat.

Inlet and Outlet Concentrations: The concentration of pollutants entering and exiting the system, often measured in mg/Nm3 (milligrams per normal cubic meter) or ppm (parts per million).

Operating Temperature: The temperature range at which the system operates efficiently.

Pressure Drop: The resistance to gas flow through the system, impacting fan power requirements.

Material of Construction: Typically mild steel, stainless steel, or specialized alloys depending on the corrosive nature of the pollutants and operating conditions.

Automation Grade: Manual, semi-automatic, or fully automatic, often controlled by PLCs (Programmable Logic Controllers) for optimal operation and data recording.

Power Requirements: Voltage, frequency, and overall power consumption.

Footprint/Space Requirements: The physical space needed for installation.

Maintenance Requirements: Frequency of filter replacement, sorbent regeneration, or other upkeep.

Waste By-products: Consideration for disposal or reuse of collected pollutants (e.g., FGD sludge from SOx removal).

Compliance with Regulations: Designed to meet specific national or local emission standards (e.g., CPCB norms in India).

Energy Efficiency: Design features like heat recovery (e.g., in RTOs) to minimize operating costs.

These systems are often integrated and custom-designed to meet the unique challenges of different industrial emission profiles.

Company Details

Business Type

Manufacturer, Supplier

Employee Count

12

Establishment

2020

Working Days

Monday To Sunday

GST NO

07EDOPK8625N1ZP

Payment Mode

Online Payments (NEFT/RTGS/IMPS), Cheque/DD, Cash

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07EDOPK8625N1ZP

New Delhi, Delhi

Proprietor

Mr. Raj

Members since

2 Years

Address

House No-151, Village Kamruddin Nagar, Nangloi Najafgarh Road, Near Do Murti, Kamruddin Nagar, New Delhi, Delhi, 110041, India

Report incorrect details