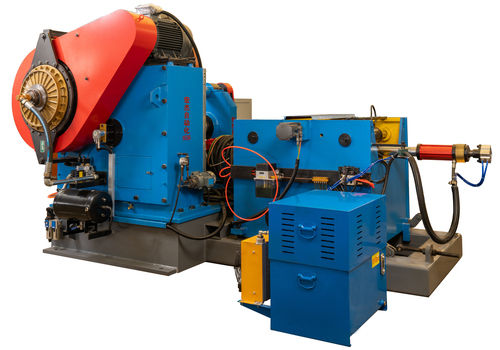

Induction Forging Machine - Igbt Technology, High Efficiency Energy Saver 15%-30% | 100% Start-up Success Rate, Modular Design, Complete Protection Functions

Price:

Get Latest Price

In Stock

Product Specifications

| Technology | Igbt |

| Power Factor | >95% |

| Startup Success | 100% |

| Energy Saving | 15-30% |

| Application | Forging |

| Features | High Efficiency, Energy Saving, Easy Operation, Modular Design, Fast Heating |

Product Overview

Key Features

IGBT (SIEMENS) technology, high conversion efficiency; Energy saving 15%-30% , compared to SCR/KGPS technology.

Much more efficient than gas-fired and coal-fired method

100% start-up success rate; power factor > 95%

Perfect and complete protection functions, increasing machine's reliability & stability

No special foundations required, Low operating cost, Easy operation

Modular design, ease of maintaining and repairing

induction hot forging machine Application:

1. Hot forming/forging of the standard components and fasteners

2. Hot forging of the automobile and motorcycle parts, metallic tools

3. Hot forging of embryo gear parts

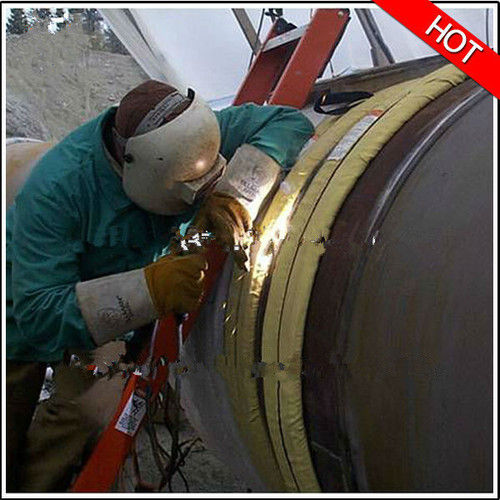

4. Heat distortion of pipes

5. Other forging applications.

6. Suitable for workpiece with various shape and different diameter

7. Customized forging production solution

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

100

Establishment

1992

Working Days

Monday To Saturday

Payment Mode

Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Chengdu, Sichuan

Ms. Ivy Chen

Address

No. 688, Southern Baoguang Road, Xindu Town Chengdu, Sichuan, 610000, China

forging machines in Chengdu

Report incorrect details