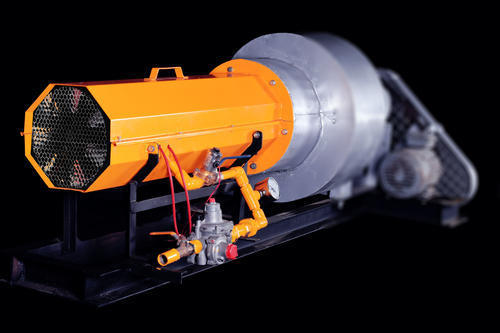

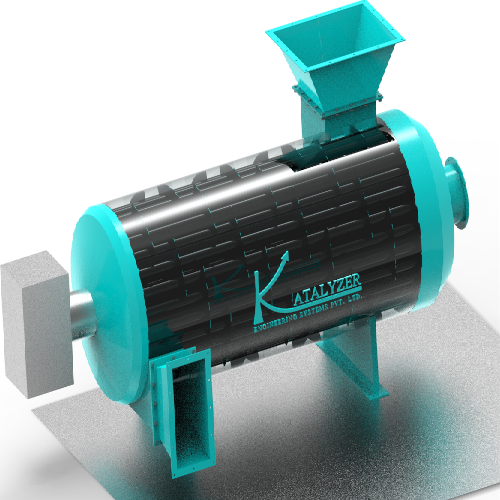

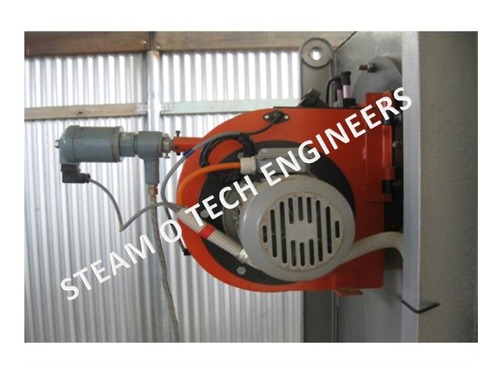

Indirect Fired Hot Air Generator

Price:

Get Latest Price

Brand Name :

Steam O Tech Engineers (i) P. Ltd.

In Stock

Product Specifications

| Fuel Type | Wood, Coal |

| Heating Method | Indirect |

| Application | Dryers, Heating |

| Usage | Various Industries |

| Efficiency | High |

| Energy Consumption | Low |

| Material | NA |

| Features | Fuel Flexibility, Indirect Heating, Wide Usage, High Efficiency, Energy Saving |

Company Details

Focusing on a customer-centric approach, Steam O Tech Engineers (I) Pvt. Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Boilers, Components & Spares in bulk from Steam O Tech Engineers (I) Pvt. Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

10

Establishment

1987

Working Days

Saturday To Thursday

GST NO

27AAECS3186J1Z0

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAECS3186J1Z0

Vasai, Maharashtra

Director

Mr Ashok Grover

Address

2, Shakti Industrial Estate, Golani Complex, Vasai, Maharashtra, 401208, India

hot air generators in Vasai

Report incorrect details