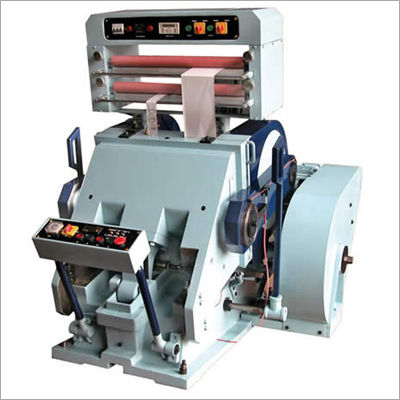

Hot Foil Attachment With Die Cutting Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Heating Plate | 3 Chambers |

| Clutch | Electromagnetic |

| Rails | Steel |

| Plate | Imported |

| Safety Guards | Approved |

| Features | Precise Cutting, Uniform Pressure, Hot Foil Stamping, Double Dwell, Safety Features, Digital Counter, Adjustable Guide |

Product Overview

Key Features

Hot Foil Attachment With Die Cutting Machine

The most ideal die cutting &

creasing platen press & world class high tech hot foil stamping

device that has been introduced for offset printing & packaging

industry matching the international standards.

What we provide with our Hot Foil

Stamping Attachment with Die Cutting Machine

- Two Tables Complete.

- Two Chase.

- Standard Service Tool Box which

contains all the needed Tools. - Machine made From Graded Casting

/Fabricated Steel. - All moving parts on the machine

are protected by Approved Safety Guards. - The digital impression counter

allows an accurate check to be kept on the number of impressions

made by the Machine. - The timing device can be set to

give a variable period from 0.5 to 10seconds. During this time the

platen remains stationary in the open position as well as the close

position before automatically resuming motion at the end of the set

dwell period. - Double DWELL Facility.

- Wrap Around Safety Device.

- Both Side Hardened and Ground-True

Imported Make Ready Plate - Automatic lubrication system.

- Adjustable guide system.

- Trip bar to stop the Machine

Immediately. - Side arm guard.

- Fly wheel drive belt full guard.

- Electro-Magnetic Clutch and

Brake standard with all machines. - Jam Release System at Extra Cost.

Features

Sticker Cutting:- Perfect

cut is ideal. The die blade should cut through the face paper &

the adhesive should come to stop just before the release of paper. We

make it cent percent possible by introducing these features.

Micropressure Adjuster:- To keep

uniform pressure on left & right side of microns.

Steel

Rails: - Movable platen runs on special grade hardened ground steel

rails to keep uniform pressure up & down.

Imported Plate:

- It is a part of our export model standard accessories with even

surface in microns, which plays key role in cutting perfect stickers,

soft crease, PVC sheets, embossing, perfect hot foil stamping

impression & any precise jobs.

Platen: Wide opening of

platen signifies operation of feedings.

- Full platen size die cuts

perfectly because moving platen is designed half round to give

perfect Punch on each and every parts of extra heavy duty. - Extra heavy duty clutch wheel,

jumbo sized connecting arms, with bronze phosphorus bushes release

platen frequently that cuts dies easily. - Hot Foil Stamping Attachment With

Die Platen Punching Machine

Hot Foil Stamping Machine Attachments

:- Attachment of hot foil unit with 1 Step, 2 Step, 3 Step or 4 Step.

Heating Plate

- 3 Chambers heating plate having 3

separate compartments with separate circuit on control panel to

operate any of three or all the three compartment at the same time.

It plays key role in minimizing wastage of electricity. - Holes are illustrated on complete

heating plate to fix blocks with screw instead of pasting. It gives

perfect registration on each & every impression. - Heating plate is fitted with

digitally displaced machine with thermostatically heaters.

Rebinder Unit:- Rebinder units are

separate for each foils.

Jumpers:- Jumpers are designed with

advanced technology to minimize wastage of foils.

Model | Foil- 35 | Foil- 40 | Foil- 46 | Foil- 53 |

Platen Size | 25 x35 in | 28 x 40in | 36 x 46in | 39 x53in |

Inside Chase | 22 x32 in | 25 x37 in | 32 x42 in. | 36 x50 in. |

Impressions per hour(Approx) | 1800 Max | 1700 Max | 1300 Max | 1200 Max |

H.P Required | 3H.P | 5 HP | 7.5 HP | 7.5HP |

Pressure Exerted during Impression | 180 Ton | 200 Ton | 260 Ton | 300 ton |

Floor Space Required | 60 x61 in | 64 x 71 in | 71 x78 in | 73 x85 in |

Weight | 3.6 Ton | 4.5 Ton | 5.5 Ton | 6.5 Ton |

Main Features

- Overhead control panel

- Three modes of operation:

- Single, continuous & timed

dwell - Hardened Ground Steel Cutting

Plate with quick release for fast make-ready. - Worm gear jam release system

(Costs Extra) - Heavy duty quality casting

- Micro pressure adjustment

- Automatic lubrication system

Safety features

- Foot Switch.

- Trip Bar.

- Overhead Guard.

- Knee Guard.

- Working Manual.

Company Details

Focusing on a customer-centric approach, BHULLAR INDUSTRIAL CORP. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Cutting Machine in bulk from BHULLAR INDUSTRIAL CORP. at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

12

Establishment

2000

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Amritsar, Punjab

Director

Mr. Varinder Singh

Address

Plot No. 8, Baba Budha Ji Avenue, Opp. ITBPF Camp, Near Ashok Vatika School, Amritsar, Punjab, 143006, India

die cutting machines in Amritsar

Report incorrect details