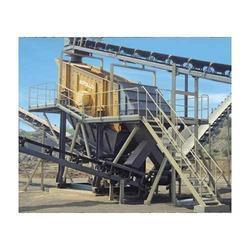

Horizontal Shaft Impact Crusher - Special Alloy Casting, Feed Size 150-300 Mm, Capacity 10-800 Tph | Adjustable Aprons, High Strength Rotor, Easy Maintenance Access, German Technology, Reliable Operation

Price: 3700000.00 INR / Piece

(3700000.00 INR + 0% GST)

Get Latest Price

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

Product Specifications

| Material | Special Alloy Casting |

| Rotor Type | Open Disc |

| Feed Size | 150-300 Mm |

| Capacity | 10-800 Tph |

| Blow Bars | High Chrome Alloy |

| Housing | Dual Split, Hinged |

| Adjustment | Hydraulic |

| Features | High Strength Rotor, Reduced Running Costs, Easy Maintenance Access, Easy Part Replacement, Long Wear Life, High Productivity, Reliable Operation, Adjustable Aprons, Cubic Product Shape, German Technology |

| Stock Quantity | 50 |

| Packsize | 1 |

| Mop | 1 |

| Product Unit | 1 Piece/Pieces |

| Moq | 1 |

| Unit Type | Piece/Pieces |

| Currency | INR |

| Price | 3700000.00 INR (Approx.) |

| Returnable | No |

| Price Type | fixed |

| Brand Name | Gujarat Apollo Industries Limited |

| Minimum Ordered Packs | 1 |

| Minimum Order Quantity | 1 |

| GSTIN | 0% |

Product Overview

Key Features

Main Features :

Apollo Secondary Impactors are built with the help of state of art

CNC machines. Stringent quality control process ensures that

the products are delivered ready to run and trouble free. The

Impact Crushers manufactured by Apollo evolved from world

famous GERMAN TECHNOLOGY and is best in the class in terms

of productivity & reliability. They are employed for secondary crushing with feed size from

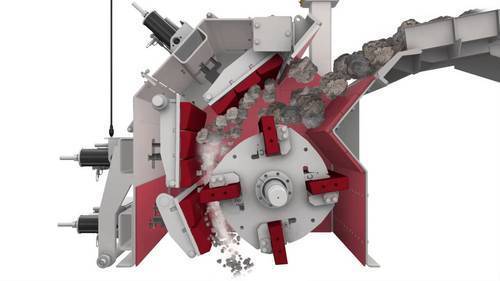

150 to 300 mm and capacities from 10 to 800 TPH. The first apron is adjustable by

means of threaded spindles and elastically clamped by means of rubber buffer. This

prevents an excessive variation of the setting during the crushera s operation. The

second apron that basically determines the product size is hydraulically adjustable

and equipped with distance plates. The third apron that increases the cubic shape

of product is hydraulically adjustable and achieved lower percentage of oversize.

Features at Glance :

* High strength open disc type stress-relieved rotor.

* Reversible high chrome or various alloy blow bars for reduced running costs.

* Dual spilt housing opening allows easy access to front or rear apron.

* Hinged crusher housing with hydraulic opening providing ease of maintenance.

* Easy replacement of wear and spare parts.

* Long wear life due to special alloy casting.

Company Details

We manufacture Rock to Road Construction Machines which includes Crushers, Static and Mobile Crushing and Screening plants, Batch Mix Plants, Drum Mix Plants, Paver Finishers, Bitumen Pressure Distributors etc. fulfills what we say ONE SOURCE UNLIMITED POSSIBILITIEScredited to our world class infrastructure facility at Ditasan, near Ahmedabad is one of the leading industrialized cities of India and German subsidiary named APOLLO MASCHINENBAU GmbH for Crusher only. Our facility is equipped with world class state of the art equipment managed by high skilled and experienced team of production personnel who consistently ensure that every production activity factors in an adherence to our established high quality benchmarks. Our large manufacturing facilities avail us to offer up to 300 TPH plant with two or three stage plant configuration.

Business Type

Exporter, Manufacturer, Supplier, Wholesaler, Dealer

Employee Count

250

Establishment

1986

Working Days

Monday To Sunday

GST NO

24AAACG7248P1Z7

Payment Mode

Letter of Credit (L/C)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AAACG7248P1Z7

Ahmedabad, Gujarat

Marketing Engineer

Mr Gambhava Zakir

Address

Parishram" 5-B, Rashmi Society, Navrangpura, Near Mithakhali Circle, Ahmedabad, Gujarat, 380009, India

vertical shaft impact crusher in Ahmedabad

Report incorrect details