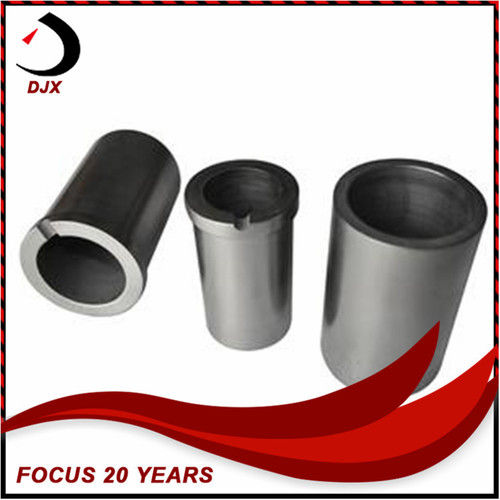

High Temperature Foundry Large Clay Graphite Crucible

Price Trend: 1.00 - 999.00 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Material | graphite |

| FOB Port | shanghai |

| Payment Terms | Delivery Point (DP), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Others, Telegraphic Transfer (T/T), Days after Acceptance (DA) |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Export Market(s) | Australia, South America, Western Europe, Middle East, Africa, Asia, Central America, Eastern Europe, North America |

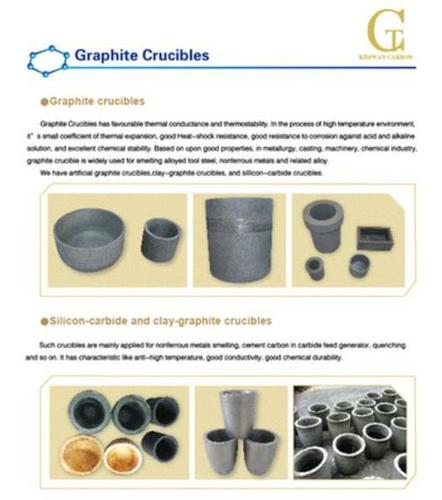

Product Overview

Key Features

Specifications:

Physical and chemical index

Refractory temperature: 1600a

Carbon content: 40%

Bulk density: 1.7g/cm3

Apparent porosity : 32%

Silicon carbide content: 24%

Advantage:

low caustic soda,low iron content,high silicon content, high temperature resistance and

refractoriness, quick heat transfer, high mechanical strength, oxidation resistance, thermal shock, high density, corrosion resistance, low porosity, stable chemical performance, good conductive performance, have a strong resistance with snap- chilling, have strong corrosion resistance of acid and alkaline solution , excellent chemical stability.

Product instructions:

1.Crucible need to stored in ventilated and dry environment, avoid moisture to affected application.

2.Crucible should be handling gently, do not roll, in case not to damage the protective layer on the surface of crucible.

3,Before use,need baking crucible,the baking temperature from low to high slowly heat up, and constantly flipping crucible and let its uniform heat, eliminate moisture , preheating temperature gradually rises to more than 500a (if preheating undeserved, will lead to blowout, spelling, this not belong to quality problems, wona t be refund)

4.Crucible furnace need mating with crucible, the gap of around need to meet the requirements, furnace cover cana t pressure on the crucible.

5.Need to avoid flame spray on the side of crucible, should be sprayed to the crucible bottom.

6.When feeding raw material, should be slowly, big size material dona t install too much and tight,avoid to crack crucible.

7.Crucible tongs need suitable with crucible, to avoid damage crucible.

8.Crucible better be continuous used, in order better to play its high performance.

9.Need to periodic rotation when using crucible, for heated evenly, prolonged use

10.When remove the slag and stick cokes of crucible, should tap gently, to avoid damage to the crucible.

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Report incorrect details