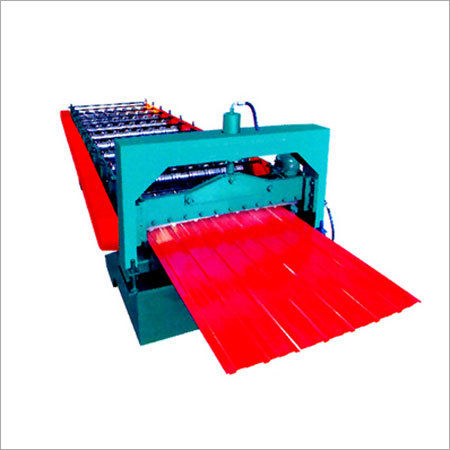

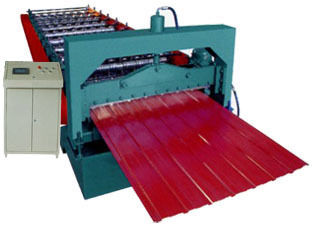

High Speed Double Layer Roll Forming Machine - High Grade No.45 Forged Steel, 9500x1670x1500mm | Automatic Plc Control, 24 Months Warranty, 20-25m/min Forming Speed

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Automatic Grade | Automatic |

| Control System | PLC Control |

| Warranty | 24MONTHS |

| FOB Port | NINGBO/SHANGHAI,CHINA |

| Payment Terms | Telegraphic Transfer (T/T) |

| Supply Ability | 15SETS Per Month |

| Delivery Time | Shipped in 70 days after payment Days |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Packaging Details | 1. 1*20GP&1*40GP container for loading one set machine with mechanical decoiler; 2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film; 3. Spare parts and some small parts packed in plastic tooling box; 4. All Components Fixed by steel wire with Container. |

| Main Export Market(s) | Australia, South America, Eastern Europe, Middle East, Western Europe, Africa, Central America, Asia, North America |

Product Overview

Key Features

1 Decoiler1set

2 Feeding & guiding device1set

3 Main roll forming machine1set

4 Hydraulic cutting system1set

5 PLC controlling system1set

6 Run out table2PCS

Main technical parameters:

1. Suitable material: color steel sheet or galvanized steel sheet

2.Thickness of raw material: 0.4-0.8mm

3. Yield strength of material: 235Mpa-345Mpa

4. Forming speed: about 20m-25m/min

5. Power Requirement

Main motor power: 7.5Kw (Depend on final design)

Hydraulic station power: 2.2Kw (Depend on final design)

6. Uncoilers loading capacity Max. Capacity: 5000kgs (can be increased to be 10T)

7. Controlling system: Mitsubishi PLC & Converter

8. Machines weight: about 12000kgs for different profile machine.

9. Machines size: about 9500*1670*1500mm (Depend on final design)

Material of Main Equipment

Roller Material: High grade No.45 forged steel, with digital-controlled procession,

Plated with hard chrome.

Active Shaft Material: High grade No.45 carbon wrought steel,which can improve the integrated mechanic feature of the shaft. Shaft diameter is 72mm.

Electric Elements: PLC control panel, transducer imported from Mitsubishi of Japan.

Other elements from famous suppliers in China

Cutter blade: Cr12 mould steel with quenched treatment

Company Details

We are manufacturer for metal roll forming machine since 2003. Good quality and reasonable rate for our customers. 1.Zhongyuan is a from raw material to the final high-precision forming machine.All are done in our factory. Your machine quality and delivery time can be controlled here if you choose us. 2.With technical support by our 20 years experienced engineers and technicians, you can get our suggestion and solution within 24 hours. 3.You can get guarantee lifetime services for our machines. 4.Simple to install and easy to maintain. >> Our machines are well installed and tested before delivery. You only need to connect some tubes and wires in your factory. Video and manual will show you how to do. >> Our experience technicians can go to your factory and train your workers. >> We have exported 85 sets machines to India since 2008. You can trust our experience and solution for your deal between us.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

60

Establishment

2003

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Hangzhou, Zhejiang

Sales Manager

Mrs May Fu

Address

No.228, Yongli, Nanyang Street, Xiaoshan District, Hangzhou, Zhejiang, 311227, China

cold forming machine in Hangzhou

Report incorrect details