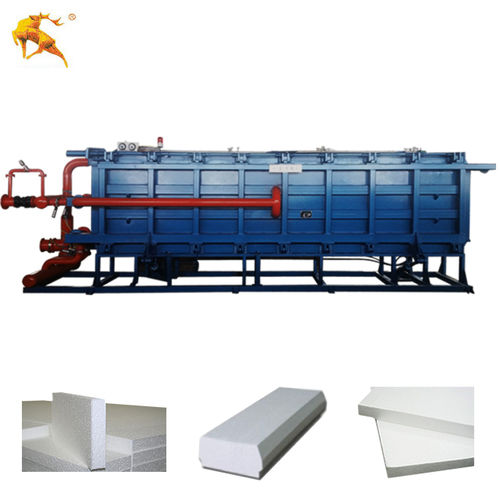

High Precision Eps Batch Pre-expander - Stainless Steel, 4500x2150x2950 Mm, Blue | Automatic Plc Control, Integrated Weighing & Drying Systems, Advanced Human-machine Interface

Price: 16000 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Material | Stainless steel |

| Computerized | Yes |

| Automatic Grade | Automatic |

| Control System | PLC Control |

| Weight (kg) | 2950 Kilograms (kg) |

| Dimension(L*W*H) | 4500*2150*2950 Millimeter (mm) |

| Color | blue |

| FOB Port | tianjin xingang port |

| Supply Ability | 1 Per Month |

| Delivery Time | 1 Months |

| Packaging Details | Outside Packaging: Standard Export Package / in wooden cases, Inner Packaging: plastic paper or wrapped with stretch film, etc for High precision EPS batch pre-expander |

| Main Domestic Market | All India |

| Certifications | ISO9001 |

Product Overview

Key Features

Main features

1. It adopts imported dedicated weighing controllers, controlled by PLC and touch screen, could measure the foamed beads weight accuracy, and give feedback timely, control the foam density by adjusting the raw material feeding weight.

2. Drying system adopts hot air curtain dry way, compared with traditional air chamber coiled tube type fluid bed drying way, hot air curtain dry way, inside air chamber heat evenly, after stop working, heat stooped, fluid bed no agglomeration.

3. Main valves, control, inspection components are imported famous brand, energy saving and ensure technology stability.

4. Steam inlet, cooling air inlet is controlled by PID valve. It makes the mixed steam temperature and pressure adjustable, realizes heating accurate, foaming evenly. Discharging adjustable, ensures and satisfies different density's different steam temperature and steam pressure requirement.

5. Level control system adopts Germany imported vibration level sensor, could perceive foaming bead rising degree correctly, control the foaming level accurately, keep foaming density tolerance minimum, realize foamed beads density evenly.

6. Weighing system adopts famous brand dedicated weighing controllers and load cell, controlled by PLC and touch screen, could control the raw material feeding weight accurately, keep the feeding tolerance minimum.

7. It has steam pressure, compressed air pressure inspection and pressure inspection for foaming barrel inside and drying barrel inside, steam temperature and foaming barrel temperature inspection, better control and master different density technology adjustment requirement.

8. Shaft sleeve under the main shaft and guide sleeve of the discharging hole adopts graphite self-lubricating sleeve, no need to add oil.

9. Feeding system adopts closed-air aspirator, avoid the air volume from the feeding fan, make the feeding fast and timely.

10. It adopts Siemens control system, choose advanced and reliable PLC and touch screen, humanized man-machine interface dialogue, satisfies control system reliable and beautiful.

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

100

Establishment

1987

Working Days

Monday To Sunday

Payment Mode

Letter of Credit (L/C)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Shijiazhuang, Hebei

Mr Gavin

Address

null Shijiazhuang, Hebei, China

foam machine in Shijiazhuang

Report incorrect details