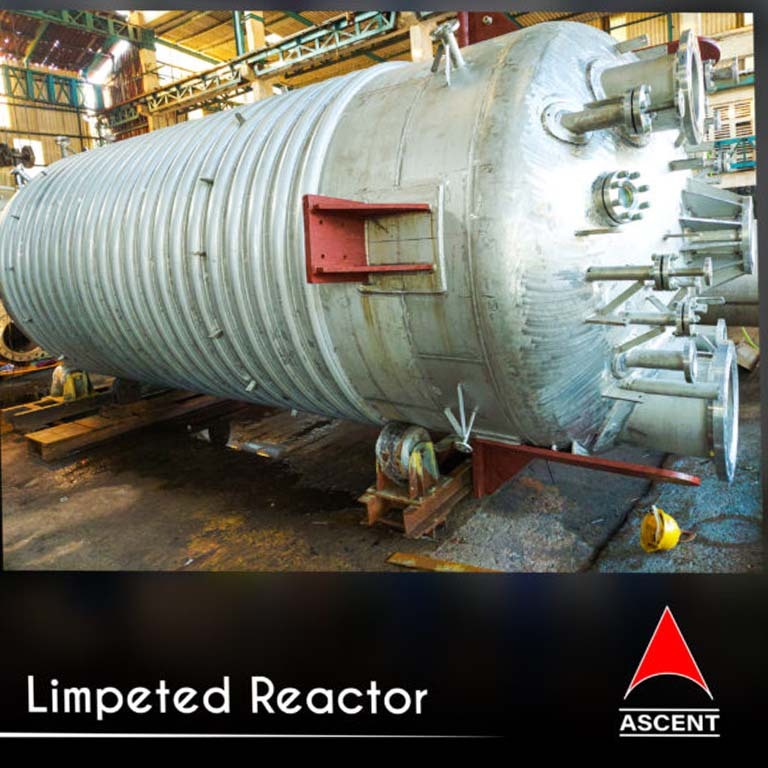

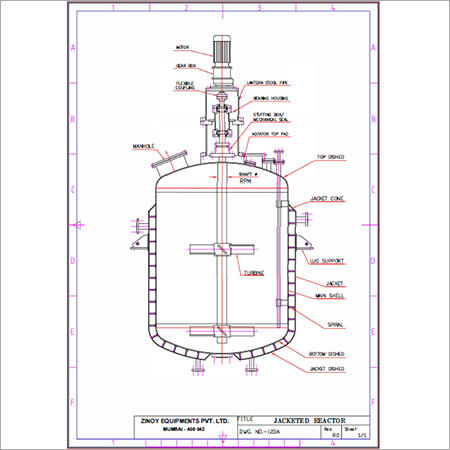

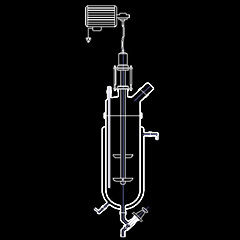

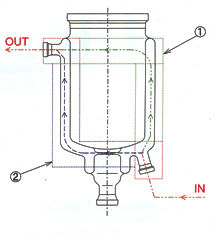

Handmade High Performance Jacketed Reactor

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Ss,Steel |

| Dimensions | Varied |

| Pressure | 76 Barg |

| Temperature | 300 Deg C |

| Agitator | Present |

| Capacity | Varied |

| Design | Cladded |

| Features | High Performance, Durable Design, Versatile Use, Safe Operation, Easy Maintenance, Cost Effective, Reliable System |

Product Overview

Key Features

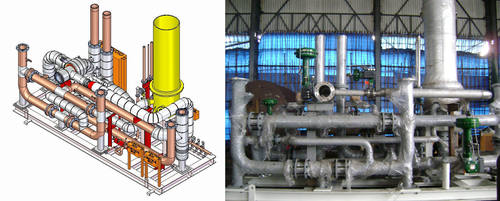

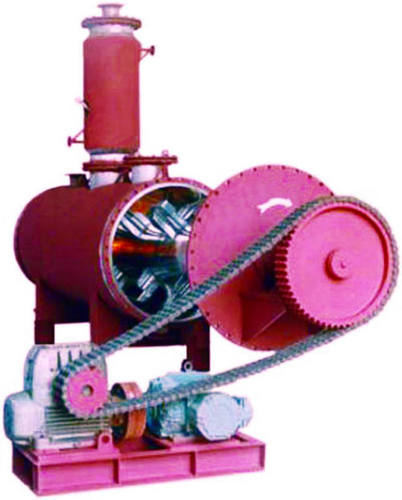

Dipesh makes standards-based reaction vessels, systems with agitators in various material of constructions for normal, aggressive and corrosive reactions.

Supplied to chemicals, petrochemicals, pharmaceuticals, paints and other host of industries, our reactors withstand the test of time. We make them in various material of construction including SS, Carbon Steel, and other exotic material. In addition, we can also design and manufacture cladded explosion bonded reactors.

Customers feel Safe and confident even at 76 barg, 300 deg C, for Hydrogenation, Chlorination, Ethoxylation, Ammonolysis, phosgenation, Carboxylation, Carbonation, Exothermic Polymerization, and many other processes, when they React with Dipesh Equipment.

We make:

Reactors with Agitators

C-GMP Reactors

Cladded Reactors

Exotic Reactors

Reaction-cum-Distillation Systems

Company Details

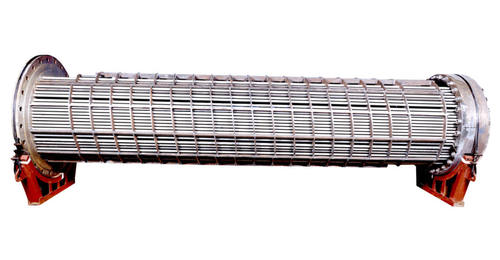

Dipesh Engineering Works (DEW) is a 40-year old company specializing in designing, manufacturing and supplying coded process equipment to global companies. We have ASME U, U2, R and NB certified shops and cater to the European market as well with CE Marking meeting PED requirements. We supply our coded process equipment, skids & systems and plants to various sectors including Pharmaceuticals, Biotech, Chemicals, Petrochemicals, Aerospace, Steel, Nuclear, Water & Wastewater Treatment, Power, Dyes & Paint among others. Thousands of our equipment have stood the test of time in harshest of operating conditions globally. Some of them include: 1. Pressure Vessels, Tanks, Receivers 2. Reactors with Heat Transfer, Agitation. 3. Agitators / Mixers for Vessels. 4. Shell & Tube Heat Exchangers. 5. Hydrogenators 6. Tall Vertical Columns 7. Rotocone Dryers / Rotary Vacuum Paddle Dryer 8. Pressure Piping & Cooling Water Piping. 9. Skids & System and Plants We have experience in handling various materials of construction including Stainless, Low Alloy, Duplex / Super Duplex, Carbon Steels, Super alloys such as Inconel, Hastelloy, Monel, Nickel, Copper, Cupro Nickel, 904L, Alloy 20, Aluminum Bronze, Aluminum and Titanium in our segregated shops. We offer jobs under third-party acceptance including Lloyds, TUV, Jacobs H&G, BVIS, Mott McDonald, Technip KTI, AKER, SAIPEM, and TCS and so on.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

40

Establishment

1981

Working Days

Monday To Saturday

GST NO

27AATFD5163A1ZG

Certification

ISO 9001 : 2015, ASME "U", "U2", "R", "NB" , ISO 14001, OSHA 18001

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AATFD5163A1ZG

Mumbai, Maharashtra

C.E.O.

Mr. Ketan J. Patel

Members since

23 Years

Address

Sona Shopping Centre, B1, Trikamdas Rd, Kandivali, Jethava Nagar, Kandivali West, Mumbai, Maharashtra, 400067, India

jacketed reactors in Mumbai

Report incorrect details