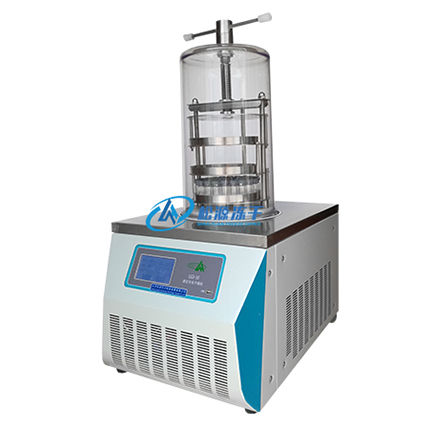

High Performance Freeze Dry Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless Steel |

| Circulating Water | Required |

| Compressed Air | Required |

| Oil Level | Normal |

| Vacuum Pump | Normal |

| Control System | Normal |

| Refrigeration System | Normal |

| Features | Easy Loading, Precise Control, Consistent Curve, System Monitoring, Accurate Meter, Safe Shutdown, Defrost Program |

Product Overview

Key Features

1. Inspection before operation

1 Check if the circulating water pressure and compressed air pressure meet the requirements.

2 Check the oil level of the silicone oil, and the oil level and color of the vacuum pump are normal.

3 Check if the compressor oil level, Freon liquid level and moisture content display color are within the normal range.

4 Check if the computer program is normal.

5 Check that the values ??of the pressure gauge and thermometer are within the normal range.

6 Check that all valves are closed.

2. Loading

1 Control the position operator to determine the program used on the control screen.

2 Start the procedure of the lyophilizer charging stage.

3 Observe the freeze-drying curve and the operation diagram of the equipment, and refer to the reference.

4 When the temperature on the graph drops to 0A C, notify the sterile room.

3. Start

After the clean room is closed, the operator of the control position will start the freeze-drying procedure immediately after receiving the notice.

4. Run

1 Note that the freeze-drying curve is consistent with the set curve.

2 Observe whether the equipment control system, vacuum system, heating system and refrigeration system are normal.

3 Observe whether the various components and each door reading action are correct during the operation in each stage.

4 The meter should be accurate and the equipment should operate without abnormal noise.

5 Observe that each oil level and liquid level should meet the requirements, and the moisture content of the refrigerant should be within the specified range.

5. Shutdown

When the drying pressure of the second stage reaches the set requirement, the operation stops. At this time, the injection compressor needs to wait for about 5 minutes to run the protection before stopping.

6. Defrost

1 Determine the parameters of the chemical box program. Start the chemical box program after checking the error.

2 Observe whether the valve switches are correct during the phlegm process. Whether the water temperature and water quantity meet the requirements.

3 The pump should be running normally. There is no water leakage at each connection point.

7. Unloading

1 Start the cooling program and carry out the product array temperature. When the temperature drops to 15A C, stop.

2 notify the sterile room to empty the discharge.

Company Details

Focusing on a customer-centric approach, Beijing Songyuan Huaxing Technology Development Co., Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Industrial Dryers in bulk from Beijing Songyuan Huaxing Technology Development Co., Ltd. at Trade India quality-assured products.

Business Type

Supplier

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Beijing, Beijing

Yutingcheng

Address

null Beijing, Beijing, China

industrial freeze dryer in Beijing

Report incorrect details