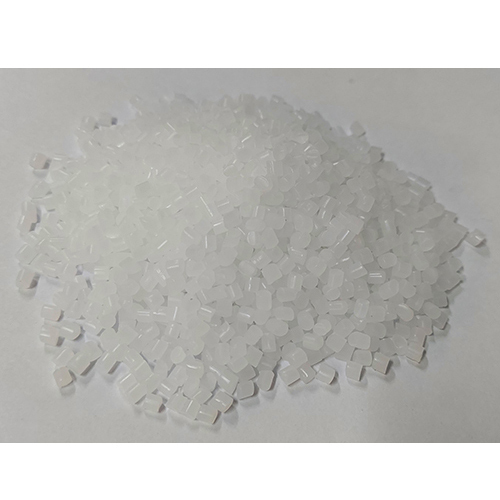

High Grade Pib Masterbatch - Polyisobutylene-based Granules, 99.98% Purity | Lightly Powdered Translucent Dry Pellets For Superior Adhesion In Stretch Film Applications

Price: 139 INR

Get Latest Price

Minimum Order Quantity :

100

In Stock

Product Specifications

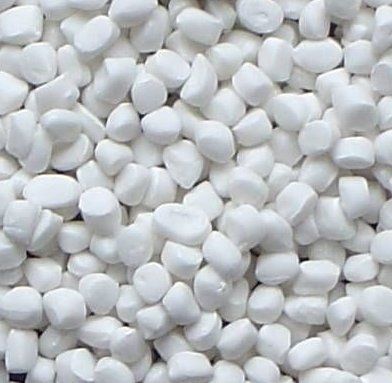

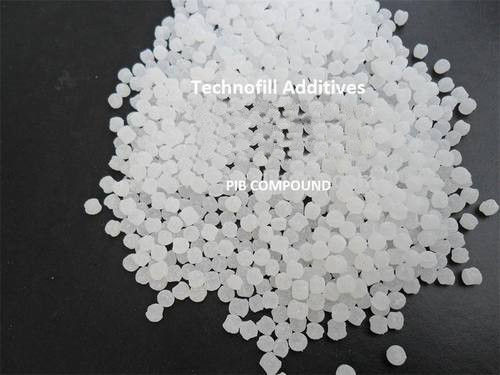

| Shape | Granules |

| Carrier | PE |

| Purity | 99.98% |

| Application | Film, Other |

| Appearance | Lightly Powdered Translucent Dry Pellets |

| Payment Terms | Cash on Delivery (COD), Letter of Credit (L/C), Western Union, Paypal, Others, Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA) |

| Supply Ability | 50MT Per Day |

| Delivery Time | 5 Days |

| Sample Available | Yes |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Packaging Details | Polyisobutylene Additive (PIB Compound) is available in the packing of 25 kg. paper laminated moisture proof woven sack bag. It is also available in 22.5 Kg. Heavy duty corrugated Box Packing. Keep the product in cool & dry place with good ventilation. Away from the direct sunlight, high temperature, rain pour and not under heavy loads. |

| Main Export Market(s) | Australia, South America, Middle East, Africa, Western Europe, Central America, Asia, Eastern Europe, North America |

| Main Domestic Market | All India |

| Certifications | QC |

Product Overview

Key Features

Polyisobutylene Additive (PIB Compound) is a based on a special blend of Polyisobutylene with base polyethylene, elastomeric olefins and active additives. The composition is used as a adhesion promoter (cling agent) to produce stretch wrap films from LLDPE or LDPE, the high molecular weight Polyisobutylene content in the base polyethylene and matrix achieves the excellent stickiness property in the dry granules, it is dry free flow granules

Polyisobutylene Additive (PIB Compound) is available in the granule form which is very easy to handle as against the direct dosing of Polyisobutylene liquid which is very difficult & tedious to handle due to high viscosity. Our Polyisobutylene Additive distributes very uniformly over the entire film imparting the strength & tackiness properties to the film with self adhesive properties. And this property of the film helps to wrap the packages together with proper grip.

Polyisobutylene Additive (PIB Compound) is designed to produce stretch wrap films from LLDPE, LDPE or any other Nonslip Polyolefina s for the applications of Pallet wrap and Silage wrap. It can be used on either blown film line or cast film process. Polymers used with Polyisobutylene Additive must not contain any Anti blocking additive or slip agent as this will prevent the migration of cling additive on the films. Migration time for the good cling properties is usually 24 to 72 hours.

We suggest the following addition level :

To get the best results in case of extrusion, it is advisable to mix the material thoroughly before feeding in a hopper

Blown Film Line:

PIB Additive, use in monolayer blown film line approx 5 to 7% should be added to with resin mix

PIB Additive, use in multilayer blown film lines are usually added to the skin layers only. Addition level Of depends on which layer is used and the thickness of layer, it can be use approx 3 to 5%

Cast Film Line:

PIB Additive, use in monolayer cast film line approx 2 to 4% should be added to with resin.

PIB Additive, use in multilayer cast film lines are usually added to the skin layers only. Addition level Of depends on which layer is used and the thickness of layer, it can be use approx 1 to 2%

Note: The above dosages are for guidance only. Actual condition may vary from film to film, process to process and also upon the thickness of the film and its specific uses.

Blown Films Application : 03 to 07%

Cast Film Application : 01 to 02%

Application:

Polyisobutylene Additive (PIB Compound ) is mainly used in LLDPE / LDPE self adhesive Stretch Film Either both plant: Blown Film Plant-Cast Film Plant

Machine Stretch Film

Stretch Silage Film

Color Stretch Film

Pre Stretch Film

Packing & Storage:

Polyisobutylene Additive (PIB Compound) is available in the packing of 25 kg. paper laminated moisture proof woven sack bag. It is also available in 22.5 Kg. Heavy duty corrugated Box Packing. Keep the product in cool & dry place with good ventilation. Away from the direct sunlight, high temperature, rain pour and not under heavy loads.

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

35

Establishment

2017

Working Days

Monday To Sunday

GST NO

24AAMFT2729F1Z5

Payment Mode

Cash on Delivery (COD)

Certification

ISO 9001 : 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AAMFT2729F1Z5

Vadodara, Gujarat

Managing Director

Mr Mandipkumar Madha

Address

Plot No: 52, Brushellz Industrial Park, Opp. GSFC Nagar Gate, Behind Toyota Showroom, Near N.H No : 08, Dashrath, Vadodara, Gujarat, 391740, India

additive masterbatches in Vadodara

Report incorrect details