Heat Treatment Services For Pto Shafts

Price:

Get Latest Price

In Stock

Product Specifications

| Payment Terms | Cash in Advance (CID), Cheque, Others |

| Supply Ability | 100 Per Week |

| Delivery Time | 1 Week |

| Main Domestic Market | Punjab |

Product Overview

Key Features

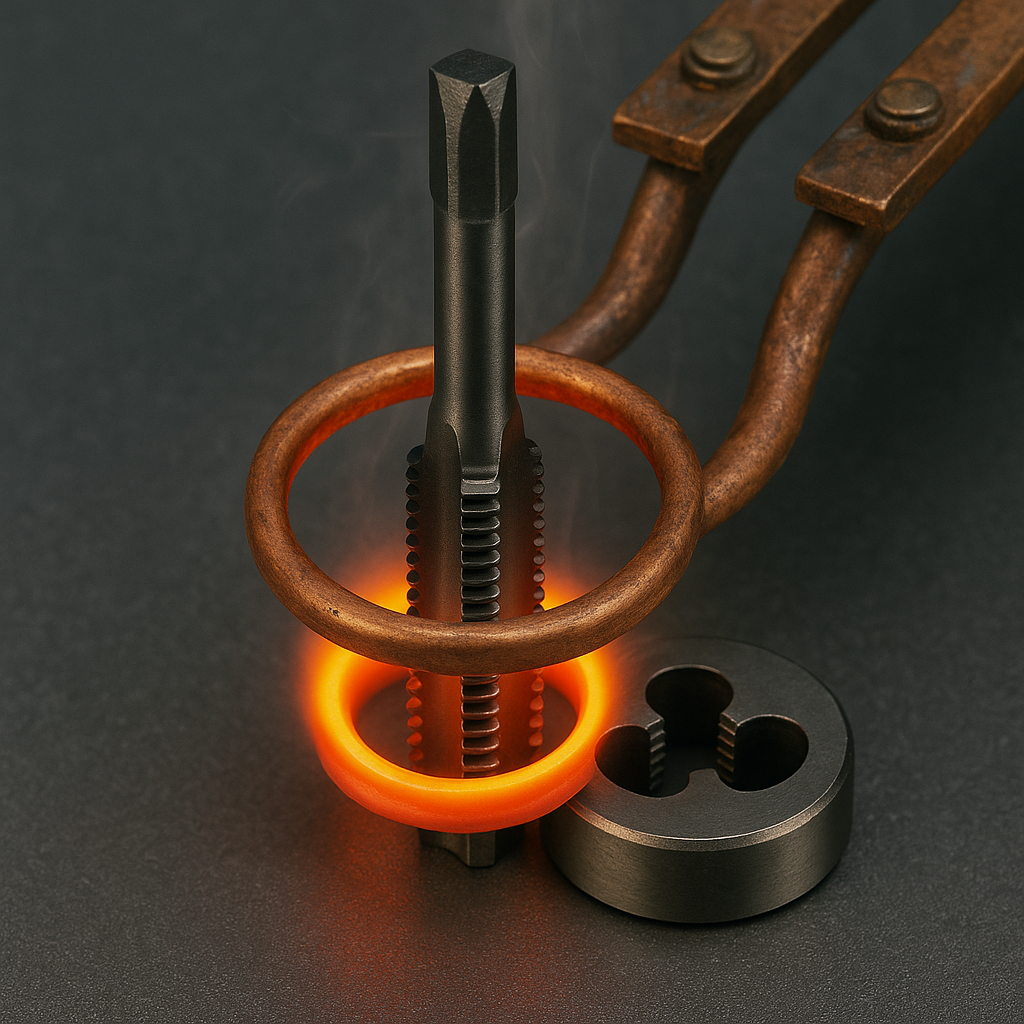

Thakur Industries proudly offers specializedInduction Heat Treatment Services for Power Take-Off (PTO) ShaftsinLudhiana, Punjab. As a leading name in precision heat treatment for agricultural and automotive components, we help enhance durability, strength, and wear resistance of PTO shafts for long-lasting performance in demanding industrial environments.

Located in Ludhiana Punjabs industrial hub we serve a wide network ofOEMs, agricultural machinery manufacturers, automotive part producers, and machine tool unitswith reliable, timely, and high-precision induction hardening solutions. Our facility is equipped with advanced induction heating machines tailored to meet the diverse metallurgical specifications and mechanical performance requirements of todays high-stress PTO shaft applications.

Why Induction Heat Treatment for PTO Shafts?Power Take-Off shafts are critical components used to transfer torque and rotational power from tractors to auxiliary equipment such as rotavators, balers, seed drills, and other farming implements. These shafts undergo repetitive torsional stress, load variations, and harsh operating conditions in both agricultural and industrial environments.

To ensureoptimum strength, toughness, and surface hardness, induction heat treatment is used to harden specific areas of the shaft, improving fatigue resistance while maintaining core ductility. This ensureslonger service life, reduced maintenance, and improved performancein real-world applications.

Service Applications and Technical BenefitsTargeted Hardening:Precision surface hardening of spline ends, yoke areas, or shaft zones as per design requirement.

Improved Wear Resistance:Enhanced hardness in critical wear zones increases the longevity of PTO shafts.

Controlled Case Depth:Customizable case depth and hardness levels based on material grade and functional need.

Faster Turnaround:High-frequency induction heating enables rapid processing with minimal lead time.

Company Details

Thakur Industries is a leading provider of induction heat treatment and case hardening services in Ludhiana. We specialize in metal hardening for auto parts, gears, shafts, tractor parts, and motor components. Our Ludhiana-based facility serves clients across Punjab with precision, durability, and fast turnaround. Contact us today for professional metal heat treatment job work near you.

Business Type

Supplier

Employee Count

12

Establishment

2007

Working Days

Monday To Sunday

GST NO

03AAJPL5676Q1Z0

More Product From This seller

Seller Details

GST - 03AAJPL5676Q1Z0

Ludhiana, Punjab

Paras Thakur

Address

1486/5, Street Number 1, Harkrishan Nagar, Shimlapuri, Ludhiana, Punjab, 141003, India

heat treatment services in Ludhiana

Report incorrect details