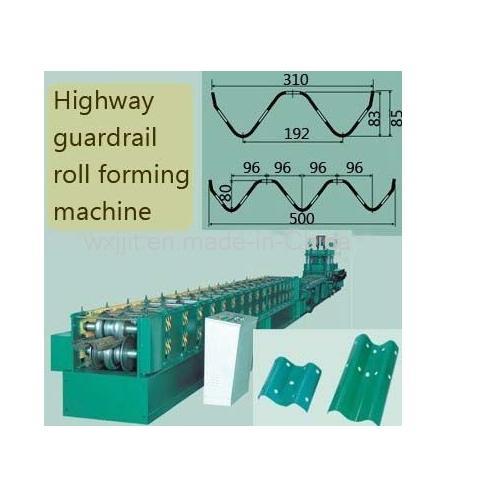

P { margin-bottom: 0.08in; Guardrail Forming Machine Driven by technical excellence we are counted as the topmost manufacture exporter and supplier of excellent quality range of Guardrail Forming Machine. Offered machine is a simple & low cost machine and is used in various industries for forming different guardrail in various design shapes and dimensions as per needs. It is fabricated by our skilled professionals using high grade basic components and latest engineering concepts in tandem with international standards. We offer this Guardrail Forming Machine in several technical specifications to meet the diverse needs of our clients at industry leading price. Special Key Features: Robust constructionEnhanced durabilityUser friendly interfaceHigh operational fluency Specifications: it is a roll forming machineguardrail roll creating machinehot sale guardrail roll making machineguardrail roll machine which is manufactured in chinaguardrail creating machine Work Flow:Decoiler alignment guiding roller nine roller levering 250T hydraulic punching hole panel transport table swift supplier photoelectrical switch roller guiding table 14 line cold curve main machine roller finished product supportable. Main Parameter of the roll forming machine: Decoiler: It has a sole arm physical expand type expand limit varies from 480-520. It has a loading capacity of 7T Alignment guiding roller: 4 roller on dual side to control the transport of the raw material. It also helps in avoiding unnecessary movement of the raw material. For instance it helps in avoiding the raw material being moved from left or right or moved up or down and it also comes with the screw adjustment9 roller levering machine: the diameter or thickness of the roller is around 115mm along with material hardness is 40CrHRC 48-52 degree. Further the width of supplier table is around 500mm and the width of flat panel 2-4 mm the power of motor is almost 5kw the ZQ 350 reducer250T hydraulic press: hydraulic motor power is at 18.5 kw; hydraulic pump is at 32 Mpa;Stand work press ranges from 10-12 Mpa; the work table size was from: 1200mmx1200mm. We will create the punch as per the requirement to make sure the flotsam will flow out of the hydraulic machine without human intervention on its own. The components of the punching head & cutting mould is: Cr12movPanel material l- transmitted table: convyor table can transport 6 m guard rail.High speed feeding machine: which is equipped with 1.5KW cycloid need reducer the diameter or width of roller is 115mm and the material hardness is 40CrHRC 48-52 degree the speed of material transport: 15m per minsPhoto electical measure unit: the precision of measure 4320+/-2mmRoller guiding material table: is generally jointing or is a passive rollerLine cold curve main machine: GY250S series in the style of door structure rolling metal band specifications is (material: Q253) width (1 to 4 mm) the diameter of the axis of roller is (80 mm) the thickness of roller is (4 mm) the rolling speed is (9 to 15m per min) approximately 1.5 to 2.5 pc of guard rail panel whose length is at 4320. The height of the material: 90 mm the material of main roller is: Gcr15 (HRC55-60). The guard rail panel has passed the JT/T281-1995 criterion of the traffic department for the guard rail panel. Main transport: 37KW ZQ 650 reducer.