Grinding Systems

Price:

Get Latest Price

In Stock

Product Specifications

| Product Type | Industrial Mill |

| Dominant Color | Blue |

| Capacity | Variable |

| Power | Variable kW |

| Particle Size | Microns |

| Material | Steel |

| Usage | Fine grinding of various materials. Suitable for ultra-fine production. |

| Dimensions | Variable m |

| Features | High Efficiency, Fine Grinding, Compact Design, Low Noise, Cost Effective, Precise Control |

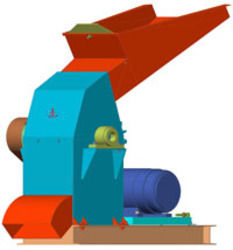

Product Overview

Key Features

Fine grinding is often the largest cost item when producing different materials because of the amount of energy consumed in the process. More efficient comminution methods are therefore sought. Dry ball mill grinding is still widely used, but other methods are often preferred as the alternatives are thought to be more cost effective.

Improvement of classification and optimization of dry grinding circuits have demonstrated substantial gains in capacity and energy requirement which makes the dry ball mill grinding circuit competitive even for grinding down to 98% - 8 m. Especially air swept mills are efficient for fine grinding as they can provide preliminary classification inside the mill. They may have 25 % more capacity than grate discharge mills. Comex can supply the complete equipment for any type of a ball mill circuit.

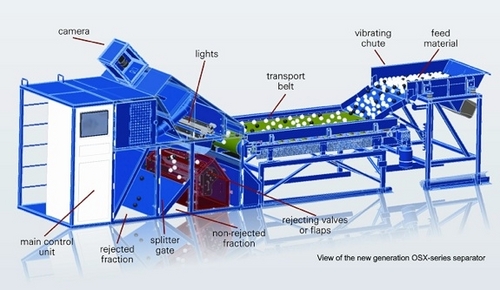

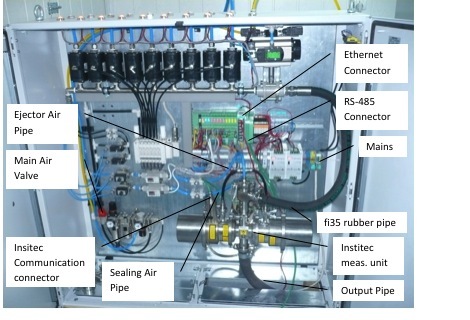

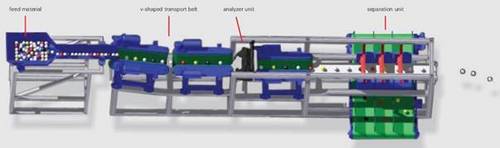

Hicom centrifugal milling is another interesting principle providing very efficient grinding. The figure shows a flowsheet of a Hicom circuit installed at the research facilities. The Hicom mill is a high-intensity tumbling mill that uses a nutating motion to generate centrifugal accelerations up to 50 times stronger than gravity. Figure shows a Hicom circuit installed at SINTEF. This circuit is equipped with on-line particle size measurement, which provides a full control of the produced material. Comex in close cooperation with Hicom can supply this type of technology on the market for any application.

The Hicom mill unit has a very small footprint, when compared with ball mills of equivalent capacity, has minimal foundation requirements, and has very low noise emissions. The mill is controlled by a programmable logic controller (PLC) which sequences start-up and shut-down procedures and monitors fault conditions. As a result of the Hicom mill's ability to directly target ultra-fine production, size and cost of downstream equipment will be smaller than alternative methods of production. Therefore, a Hicom circuit provides opportunities for boutique production, applications at sites with limited space or where real estate costs are at a premium.

Company Details

Focusing on a customer-centric approach, COMEX AS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Processing Machines & Equipment in bulk from COMEX AS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier, Trading Company

Employee Count

60

Establishment

2003