Grinding Ball Mill Machine - 0.8-230 T/h Capacity Eco Friendly & High Efficiency Design | High Performance Low Noise Plc Control

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Product Type | Ball Mill |

| General Use | Stone/ Ore/ Coal/ Cement etc |

| Capacity | 0.8-230 t/h Cubic Meter (m3) |

| Computerized | Yes |

| Automatic | Yes |

| CNC Or Not | Normal |

| Control System | PLC Control |

| Feature | High Performance ECO Friendly Low Noise Lower Energy Consumption High Efficiency |

| Warranty | 1 year |

| FOB Port | Qingdao Shanghai Tianjin |

| Payment Terms | Telegraphic Transfer (T/T) Paypal Cash on Delivery (COD) Western Union Cash Advance (CA) Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Cash Against Delivery (CAD) Delivery Point (DP) Days after Acceptance (DA) Cash in Advance (CID) Cheque |

| Supply Ability | 100 Per Year |

| Delivery Time | 30 days after signing the contract Days |

| Packaging Details | Standard export container bulk spare parts in wooden box |

| Main Export Market(s) | Australia North America Eastern Europe Middle East Western Europe Africa Central America South America Asia |

| Certifications | CE ISO |

Product Overview

Key Features

--------------------

- Most professional ball mill

- Energy-Saving about 20%~35%.

- Stable performance

- Most Competitive Price

--------------------

1. Introduction:-

Ball mill machine is the key equipment for recrushing the materials after they are primarily crushed. It is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement silicate product new building material refractory fertilizer black and non-ferrous metals and glass ceramic industry. The ore grinding methods of ball mill include dry type and wet type.

-------------------

2. Features:

1) Ball mill is an efficient tool for grinding many materials into fine powder.

2) The ball mill is used to grind many kinds of mine and other materials or to select the mine

3) Ball mill is widely used in building material and chemical industry.

4) There are two ways of grinding: the dry way and the wet way.

5) Ball mill can be divided into tabular type and flowing type according to different expelling mine

6) To use the ball mill the material to be ground is loaded into the neoprene barrel that contains grinding media.

7) As the barrel rotates the material is crushed between the individual pieces of grinding media that mix and crush.

Company Details

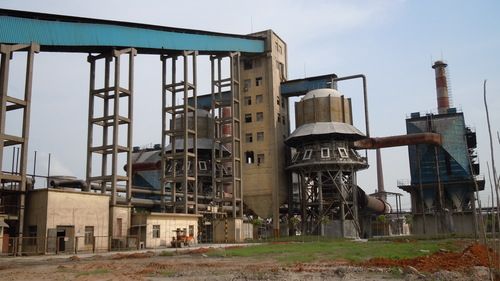

Henan Zhengzhou Mining Machinery Co. Ltd. Henan zhengzhou mining machinery co.ltd is leading mining equipments manufacturing in the world who has provided innovative technology and products for mine and energy of over 100 countries and district. It is built in 1956 and locates its factory in xinngyang henan china. It is appointed as the fixed equipment-providing factory by chinese ministry of machine building and henan mechanical electronic bureau. The development during the last half century has witnessed its capital assets being over rmb100000000 and becoming a comprehensive modern enterprise with the service of scientific research design manufacture sales installation commissioning and worker training. The production lines provided by us mainly include: magnesium production line cement production line lime production line ore dressing line and oil proppant production line main products include: rotary kiln ball mill granulator bucket elevator vertical preheater vertical cooler crusher.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

200

Establishment

1956

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Zhengzhou, Henan

Mr. Zhang

Address

Qiaoloucaizhai Industrial Park XingYang Zhengzhou Henan 450000 China

ball mill in Zhengzhou

Report incorrect details