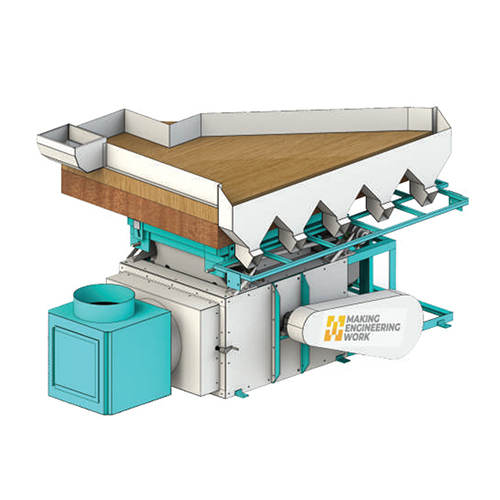

Gravity Separator - Wooden/iron Plate Construction, Adjustable Feed Rate & Eccentric Speed, Efficient Air Adjustment For Superior Material Separation

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Iron/Wood |

| Dimensions | Variable |

| Capacity | Variable |

| Power | Variable |

| Weight | Variable |

| Adjustments | 5+ |

| Separation | Gravity/Air |

| Features | High Efficiency, Precise Separation, Easy Operation, Durable Design, Versatile Use, Cost Effective, Improved Quality |

Product Overview

Key Features

Gravity Separator

diamond ENGINERING WORKS is pioneer in manufacturing various food industries and agro-industries machinery to meet customized requirement of agro processor form time to time. Company having attached with agro industries since four decades has developed the state of art manufacturing facility to delivery efficient products as per generation requirement.

Our Gravity Separator is widely used for various materials like Pulses, Coffee Beans,

Working principal:

Diamond Gravity Separator works on principle of Separation of grains thru Gravity or Weight and forced air, initially the fans is kept off while introducing the grains particle on the deck of machine. Now in second stage the fans is switched On so the induced air will lift the particle in air , here the heaviest particle will be near the surface of deck and lightest particle will be above the surface of deck. In Third stage the Vibration of deck is operated in such way that the combine effect of air and vibration will separate the material in layers. With heavier layers on the bottom and lighter layers on the top of Deck. Thus these frequent operations will cause material to separate according to its gravity.

1) PARTICLES OF THE SAME SIZE BUT WITH DIFFERENT SPECIFIC GRAVITIES CAN BE SEPARATED

2) PARTICLES OF THE SAME SPECIFIC GRAVITIES BUT WITH DIFFERENT SIZE WILL BE GRADED ACCORDING TO THE SIZE OF THE PARTICLES.

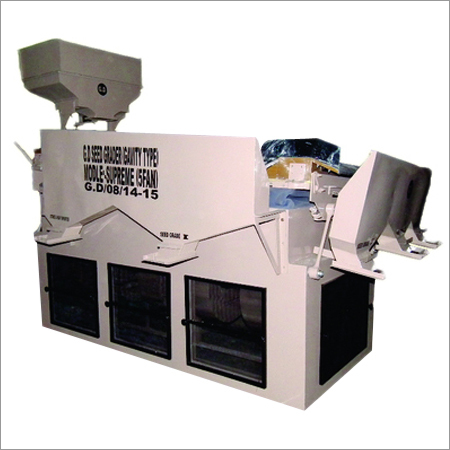

Construction :

The machine is constructed using wooden/iron plate. The main part of machine is its upper Deck on which materials is feeded for separation. Under the deck is a cover in which air pressure is maintained. The separation takes place on screen or cloth.

FEED Rate: This adjustment is located on Feeder, it mainly control the amount or volume to be feed to deck. The feed rate should be kept at minimum at starting point, so to keep deck uncovered and to efficiently separate material as per the gravity.

Rear or End Raise: This raise is to adjust the flow of material from feeder to discharge end. It should be kept as per material requirement.

Side tilt. : It is used to adjust the horizontal tilt of deck.

Eccentric Speed: The eccentric speed can be adjusted or increased / decreed as per the requirement. The high eccentric sped will make material to move to high side of deck

Company Details

Focusing on a customer-centric approach, DIAMOND ENGINEERING WORKS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Food Processing Machinery in bulk from DIAMOND ENGINEERING WORKS at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

20

Establishment

1951

Related Products

More Product From This seller

Seller Details

Ahmedabad, Gujarat

Proprietor

Mr. Diamond Engineering Works

Address

Dudheshwar Road, Opposite E.S.I.C. Hospital, Near Nagori Estate, Ahmedabad, Gujarat, 380004, India

gravity separator in Ahmedabad

Report incorrect details