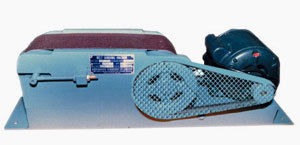

Geosyn Double Discs Grinding / Polishing Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Number of Discs | Two |

| Disc Diameter | 20cm |

| Motor Power | 1/4 HP |

| Voltage | 220/240V |

| Frequency | 50Hz |

| Speed Control | Stepless |

| Max Speed | 1200 RPM |

| Material | Stainless steel |

| Dimensions (LxWxH) | 45x23x36cm |

| Weight | 275kg |

| Usage | Grinding and polishing of materials like brass,lapis |

| Features | Double discs, Stepless speed, Durable build, Easy operation, Precise control, Efficient polishing, Water cooling |

Product Overview

Key Features

No. of Discs :

a) For grinding one 20cm.dia.m.s./brass lapis provided.

b) For polishing one brass20cm.dia.discwith adaptor for holding polishing papers / cloth etc.

c) Capacity two discs of 20cm.dia

Working Basins :

Two s.s. working basins (in which the grinding / polishing discs rotate) providedwith detachable splash guards.

Drive : Two separate 1/4 HP DC motors, having 220/240 V AC, 50 Hz input.

Speed of Discs (RPM) : Each disc is steplessly variable from 0 - 1200 RPM.

Control Panel : Two separate control panels each having :- Push button type ON/OFF switch with overload protection fuse. Rotatable speedcontrol knob and analogue type speed indicator.

Water Arrangement :

a) Inlet:- G.I.Pipe - 1/4a dia. with brass nozzle

b) Outlet:- G.I.Pipe - 1/2a dia.

c) Built-in S.S.Wash basin.

d) Two swivel type taps with flow controlvalve for water supply on discs/basin.

Disc Guard : Two separate acrylic disc guards withlifting knob provided.

Electrical Cable : 2 mtrs. of flexible electrical cable with15 Amps.plug top.

Dimension : L 45a x W 23a x H 36a approx.

Shipping Weight : 275kg.approx.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

30

Establishment

1962

Working Days

Monday To Sunday

GST NO

19AABCG0387N1Z7

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 19AABCG0387N1Z7

Kolkata, West Bengal

Director

Mr Sumit Guha

Members since

25 Years

Address

Plot No. 137, Biplabi Rash Behari Basu Road, Canning Street, 1 St Floor, Room No.-25, Kolkata, West Bengal, 700001, India

polish machine in Kolkata

Report incorrect details