Fume Extration System

Price:

Get Latest Price

In Stock

Product Overview

Key Features

We have developed a large customer base

in the national as well as in international market by manufacturing and

supplying superior quality Fume

Extraction System. It is

manufactured with the utmost precision by our adept team. Mainly used for extracting

the fume from industrial places, this is widely demanded by our customers. Clients

can avail this Fume

Extraction System from us at marginal prices.

Features:

- Robust construction

- Excellent performance

- Longer working life

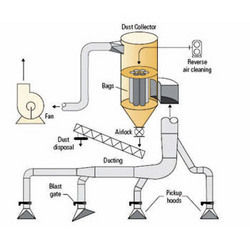

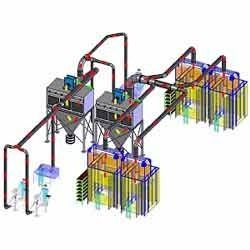

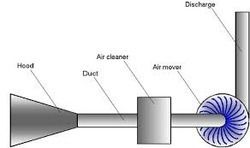

Dust/Fume Extraction System:

In thermal power stations, Metal Industry, Coal/material conveying is one of the most important steps. Coal/Material handling system mainly consists of unloading, screening, crushing, stacking, reclaiming and bunker feeding equipment arranged in an optimum configuration. Coal or bulk solids are received at site either by ships or by rail-wagons or by trucks. It is then conveyed for screening and crushing. For smaller capacity plants, either conveyor with traveling tripper or conveyor with telescopic chute is generally used for stacking the crushed coal andreclaimed using bridge type scraper reclaimer or underground reclaim hopper with suitable capacity dozers.

Dust generation in a plant:

Loading point, Unloading point of belt conveyor, Discharge Chutes: Dust from the operation of belt conveyors originates mainly at the trail pulley where material is received and at the head pulley where material is discharged. Dust generation depends on belt width, speed, height of fall of coal.

Bunker Feeding Point: Crushed coal either directly from crushers or from the crushed coal stockyard is conveyed to boiler bunkers through traveling trippers or reversible shuttle conveyors. Dust is generated while loading the bunkers, spreading of which is controlled to some extent by conveyor sealing arrangement, and needs to be extracted from bunkers.

Crusher area: Crushers are used for size reduction in the coal or other particle. The huge gyratory or roller crushers are used for primary size reduction, while jaw or gyratory crushers are used for secondary size reduction. Large side hoods are used for dust extraction.

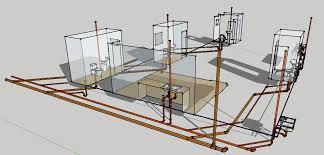

Process:

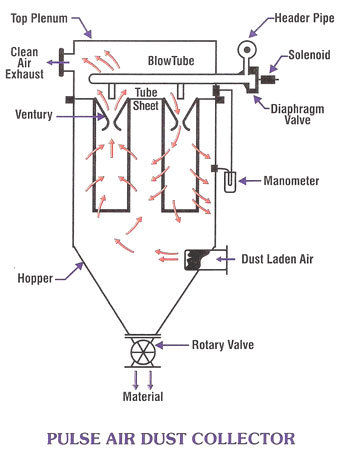

The arrangement for dust extraction system for bunkers consists of eight Suction points, four on either side of Tripper Conveyor. The Tripper Conveyor feeds only two feeding points out of the eight, at a time. Thus for those two feed points, corresponding two suction hoods sucks dust laden gas in the system. While other six feeding points are closed using belt sealing arrangement. This dust laden gas is carried to the bag filer through interconnecting ducting.The gas is filtered through the bags due to the entrapment of dust particles into filter media. Each row of the bags, receives periodic pulses of compressed air, thus pulsing the bags, thereby dislodging the dust to the hopper. The pulsejet system is provided with a pressure switch to control the maximum pressure in the air header. The pressure drop across the bag house is measured by a Differential pressure Indicator or by a water tube manometer. In case of the excessive pressure drop, a Differential pressure switch comes into operation and provides a signal, which would be interlocked with Control Panel. The dislodged dust is collected in the hopper and discharged through the RAV. RAV is provided with zero speed switches to ensure overload protection of Geared motor. To improve the flow characteristics or to avoid chocking, rat holing, arching of dust in the hopper, Pneumatic knockers are provided on the hopper.

In order to control maximum level of dust in the hopper, a Level switch is provided. The level switch is to be interlocked with the control panel so that the dust level in the hopper should not rise above the set level. Coal dust is combustible and tends to form dust clouds, hence precautions for is taken by providing vent, to reduce the risks of property damage and personal injury. The Fan provided develops the necessary draft. The draft control of the Fan is carried by VFD. The VFD is provided with PID controller. The PID controller receives the signal from Differential pressure transmitter across the Flow measuring device, and gives controlling signal to VFD, to maintain necessary RPM of fan thereby maintaining necessary draft in the system. The clean air is discharged at the outlet of I.D. Fan.

Company Details

Focusing on a customer-centric approach, WHIZZ ENGINEERING SERVICES PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get Pollution Control & Monitoring Equipment from WHIZZ ENGINEERING SERVICES PVT. LTD. at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

10

Establishment

1999

Working Days

Monday To Sunday

GST NO

27AAACL8654J1Z4

Related Products

More Product From This seller

Seller Details

GST - 27AAACL8654J1Z4

Pune, Maharashtra

Address

Survey No. 15/1, Gujarwadi Road, Katraj Nagar, Pune, Maharashtra, 411046, India

Pollution Control & Monitoring Equipment in Pune

Report incorrect details