Fully Continuous Waste Tyre Pyrolysis Plants

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Power | 3-Phase |

| Dimensions | Large |

| Weight | Heavy |

| Capacity | High |

| Voltage | 220V |

| Type | Hydraulic |

| Features | High Output, Durable Design, Easy Operation, Precise Molding, Cost Effective, Efficient Process, Versatile Machine |

Product Overview

Key Features

The technology we are using for waste recycling is "pyrolysis". Pyrolysis is a green technology for waste recycling. It recycles waste tire, waste plastic and waste rubber into fuel oil. It's a renewable energy and help fuel to our environment. It solves environmental pollution which is becoming a serious problem in everywhere. I believe it's a meaningful industry.

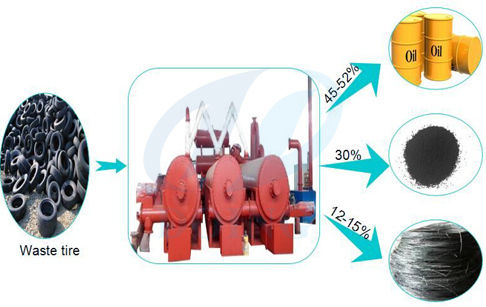

From 1000kg tires, you can recover 450kg furnace oil, 300kg carbon black and 150kg steel wire, if it's whole tires. This is just a normal rate. If you remove steel wire before doing pyrolysis, or cut tires into pieces, the oil yield is higher accordingly.

As we see in our usual life, plastic products are usually mixed together by different kinds of materials. So unlike waste tires or rubber, it's a little hard to give a certain number of oil yield from waste plastics. From PE you can recover 95% oil, from PP and PS you can recover 90% oil, and it's 40% for ABS. But PVC and PET are not working with pyrolysis machine. So the oil yield.

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Wholesaler

Employee Count

500

Establishment

1976

Working Days

Monday To Sunday

Certification

ISO9001

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Zhengzhou, Henan

Mr Julia Ge

Address

No. 138 Yingxie Road, Jinshui District, Zhengzhou, Henan, 450000, China

tyre pyrolysis plant in Zhengzhou

Report incorrect details