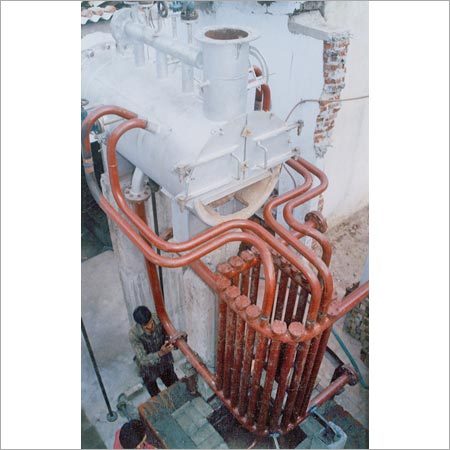

Fully Automatic Production Line For 240/310/480/520 Transformer Radiator By Cangzhou Kenuo International Co., Ltd.

Price:

Get Latest Price

In Stock

Product Specifications

| Panel width | 520mm |

| Panel length | 1000-4000mm |

| Central distance | 500-4000mm |

| Central distance error | +/-1.0mm |

| Oil channels | 7 |

| Suitable material | ST12, SPCC, DC01 |

| Material thickness | 1.0-1.2mm |

| Usage | Transformer radiator production |

| Features | Fully automatic, High quality, Efficient, Economical, Competitive, World-class |

Product Overview

Key Features

I. General

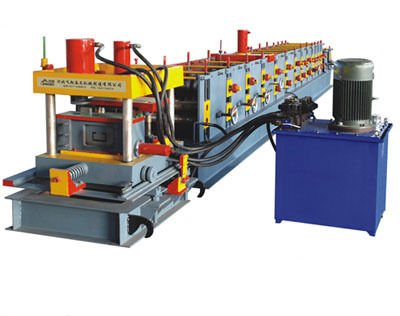

Our automatic radiator (for transformer) production line mainly absorbed, improved & updated the technology and design of Germany GEORG & Canada MTM. Our machine performance reaches the international standard class, and the price is much economical and competitive. The whole line is composed of automatic decoiler, roll former, multiple spot welder, side seam welding machine, head welding machine, head cutting machine, and forwarding table, etc. The radiator size is 520mm, panel length is 1000mm-4000mm. The whole line is fully automatic, the product quality is good, and the performance reaches the first-rate in the world.

II. Work flow

Decoiling A roll forming A hydraulic press A multiple spot welding A side seam welding A head welding A head cutting A end product

Equipment includesi

1. Hydraulic decoiler 5MT

2. Roll former for the sheet forming

3. Hydraulic press for head punching and cutting

4. Servo feeding conveyer

5. Multi-Spot Welding Machine

6. Side Seam Welding machine(Dual Welding)

7. Head Seam Welding Machine

8. Head cutting machine

9. Conveyers between the machines

Optional accessory machines

1. Header pipe notching machine (new model)

2. Assembly table

3. Turn over table for assembling welding

III. Technical common data

The panel profile is a unique design, providing efficient flow characteristics and a stable radiator structure to facilitate manufacturing. The formed profile is 520mm. It uses 6 formed flutes to produce 7 oil channels.

1) Panel width: 520mm

2) Central distance: 500 - 4000mm (when less than 1000mm, cana t use automatic production method)

3) Central distance error: +/-1.0mm

4) Single piece bearing pressure: positive pressure a Y 0.15MPa; negative pressure a Y133KPa. No deformation.

5) Oil channel clearance:

When material thickness 1.0mm: a Y11mm

When material thickness 1.2mm: a Y11.5mm

6) Quantity of oil channels: 7

7) Suitable raw material: ST12, SPCC, DC01 cold roll steel

8) Material thickness: 1.0-1.2mm

9) Coil sheet width: 530mm

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

130

Establishment

1995

Working Days

Monday To Friday

Payment Mode

Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

Related Products

More Product From This seller

Seller Details

Cangzhou, Hebei

Director

Mr Owen Ge

Members since

10 Years

Address

Cangzhou Industrial Zone, Cangzhou, Hebei, 061000, China

Industrial Machinery & Parts in Cangzhou

Report incorrect details