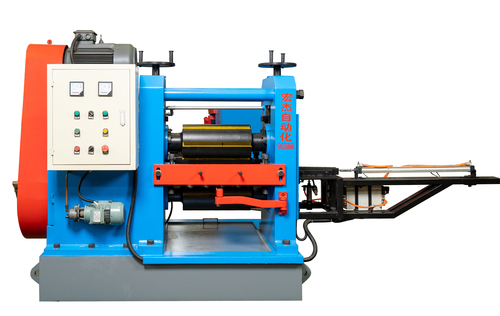

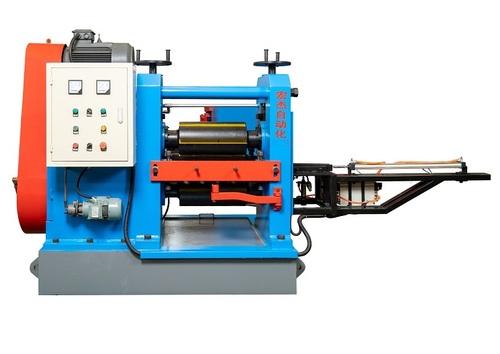

Forging Roller Machine - Color: Blue

Price: 60000 USD / Set

Get Latest Price

Minimum Order Quantity :

1 Set

In Stock

Product Specifications

| Material | Aluminium |

| Weight | 15000 Kilograms (kg) |

| Color | Blue |

| FOB Port | Qungdao |

| Supply Ability | 1 Per Month |

| Delivery Time | 4 Months |

| Packaging Details | Wooden Box |

| Main Export Market(s) | Asia, Australia, Central America, North America |

| Main Domestic Market | All India |

| Certifications | CE |

Product Overview

Key Features

Roll forging is a vital metalworking process that involves the continuous deformation of metal through the use of rotating rolls under intense pressure. Unlike traditional forging methods that rely on sudden impact or hammering, roll forging shapes the material gradually as it passes between two or more rotating rolls, which compress and form the metal into specific dimensions and geometries. This process is widely utilized in industries requiring high-strength components, particularly in automotive, aerospace, and heavy machinery manufacturing.

In roll forging, the metal-usually in the form of a heated billet or bar-is passed through rolls equipped with specially designed grooves. As the metal moves through the rolls, its cross-sectional area is reduced, and the material is plastically deformed. This plastic deformation alters the internal structure of the metal, refining its grain size and improving its mechanical properties, such as strength, durability, and resistance to fatigue. Roll forging can be performed either as hot forging, where the metal is heated to increase malleability, or as cold forging, which allows for greater precision in the finished product but is typically used for less complex shapes.

Roll forging has found extensive use in various industries due to the unique benefits it offers. In the automotive industry, the process is integral to the production of critical components like crankshafts, connecting rods, and gears. These parts are essential to engine function and drivetrain performance, where strength and fatigue resistance are paramount. Roll forging enhances these properties by aligning the metal's internal structure and eliminating defects that could lead to mechanical failure.

In roll forging, the metal-usually in the form of a heated billet or bar-is passed through rolls equipped with specially designed grooves. As the metal moves through the rolls, its cross-sectional area is reduced, and the material is plastically deformed. This plastic deformation alters the internal structure of the metal, refining its grain size and improving its mechanical properties, such as strength, durability, and resistance to fatigue. Roll forging can be performed either as hot forging, where the metal is heated to increase malleability, or as cold forging, which allows for greater precision in the finished product but is typically used for less complex shapes.

Roll forging has found extensive use in various industries due to the unique benefits it offers. In the automotive industry, the process is integral to the production of critical components like crankshafts, connecting rods, and gears. These parts are essential to engine function and drivetrain performance, where strength and fatigue resistance are paramount. Roll forging enhances these properties by aligning the metal's internal structure and eliminating defects that could lead to mechanical failure.

Company Details

Zibo Hongjie Forging Industry Equipment Co., Ltd. has been a well-established company in the forging industry for more than 30 years. Our primary focus has always been on the design, development, production, and marketing of roll forging machines, cross wedge rolling machines, and related auxiliary equipment. As a manufacturer and exporter, we are famous for our Die Press Autoparts Roll Forging Machine, Metal Cutting Band Saw Machine, Bucket Teeth Production Line, Integrated Automatic Induction Heating Equipment, Precision Punching Machine, etc. We are completely dedicated to providing the most cutting-edge equipment and technical support to customers across the world. We stay well-aware of the importance of modern forging machines in diverse industries and have adopted practices and plans to meet their demands.

Business Type

Manufacturer, Service Provider, Distributor, Supplier, Trading Company

Employee Count

200

Establishment

1994

Working Days

Monday To Friday

Payment Mode

Online Payments (NEFT/RTGS/IMPS), Cheque/DD, Cash

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Zibo, Shandong Sheng

Ms. Ella Gao

Members since

2 Years

Address

B1009, Runde Building, No.6, Xinhuan East Road, Fangzhen Town, Zhangdian, Zibo, Shandong Sheng, 255000, China

Report incorrect details