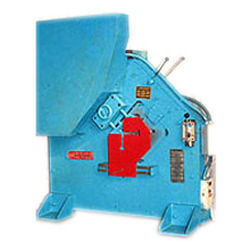

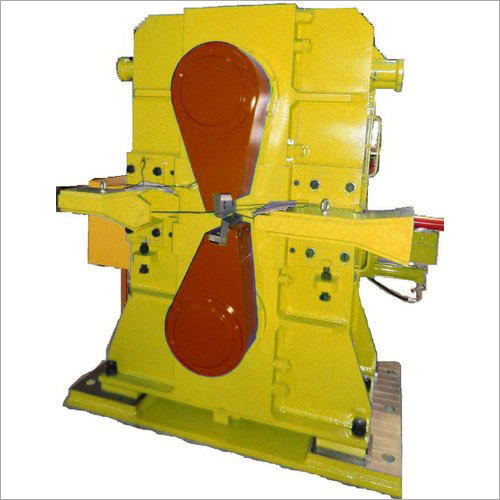

Flying Shear - 1000 Mm Crs Design For High-temperature Cutting | Involute Profiled Cutters, Water-cooled Design, Optional Flywheel System

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless Steel |

| Capacity | 40-140 Ton |

| Dimensions | Variable |

| Power | Electric |

| Weight | Heavy |

| Punching Speed | Fast |

| Warranty | 1 Year |

| Features | High Durability, Precise Cropping, Efficient Punching, Robust Design, Corrosion Resistant, Increased Productivity, Reduced Downtime, Versatile Operation, Cost Effective |

Product Overview

Key Features

To cut the T.M.T. Bar at a temperature of 500oC and above to the required lengths.

Product Features:

The 1000 mm CRS (adding to the manufactures cost because with 1000 mm centres the depth of the shear also has to be increased leading to increased dia gears, shaft lengths, casing weight) instead of 800 or 850 CRS so as to reduce the base rpm of the drives Motor. Since it is a start stop shear the motor shall have to accelerate to lower (base) rpm hereby reducing power consumption on recurring basis and generate payback.

The casing is prestressed to prevent seperating of casing parting surfaces on load during the milli seconds when the cut is executed.

The cutter ends are involute profiled at ends. The cutters engage before the bar touches the cutting edge, eliminating possibility of erroneous blade over lap.

We provide an optional arrangement of Flywheel with mechanical clutch. The flywheel is engages for cutting above 20 mm bar size. The flywheel inertia augments the lower power available from constant torque motor running at low rpm to match thicker bar rolling speed.

The casing front end and pinch roll cantilever shaft is water cooled to avoid distortion with heating.

The gears are case carburised hardened & ground designed for minimum back lash. Again the gears and knife holders are designed for minimum intertia.

Company Details

Focusing on a customer-centric approach, NAVBHARAT ENGINEERING WORKS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Rolling Mill Machinery in bulk from NAVBHARAT ENGINEERING WORKS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

500

Establishment

1986

Certification

9001:2008

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Ghaziabad, Uttar Pradesh

Manager

Mr. Raghav

Address

C-233, Bulandsehar Road, Industrial Area, Site 1, Ghaziabad, Uttar Pradesh, 201001, India

flying shear machine in Ghaziabad

Report incorrect details