Max Filtration - Semi Circular Basin System | Efficient Ferrous and Non-Ferrous Particle Removal High Purification for Grinding and Machining

Price:

Get Latest Price

In Stock

Product Specifications

| Filtration Type | Paper Band |

| Application | Rolling Mills |

| Basin Shape | Semicircular |

| Pressure Type | Hydrostatic |

| Outlet | Vertical |

| Features | High Purification Filters Particles Improves Finish |

Product Overview

Key Features

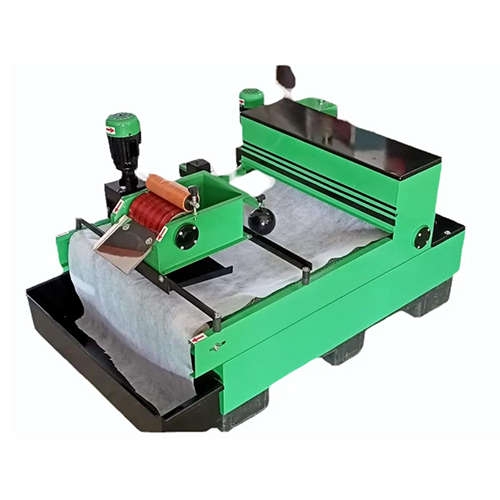

Max filtration offers the excellent means of filtering both ferrous and non-ferrous particles where high degree of purification is required and contaminate differ in sizes and composition. Max filtration is required for grinding honing transfer lines and machine center. It also can be used for rolling mills for filtering coolant which helps in improving the surface finish of sheet.

Procedure: The filtration procedure take place in a semi circular shaped basin with hydrostatic pressure. Two thick wheels from the lateral sealing of the filtration basin. There are a number of waste removers between the disc wheels which push out all the dirt. The filtration is centric. The outlet occurs throughout the whole area in a vertical downward direction.

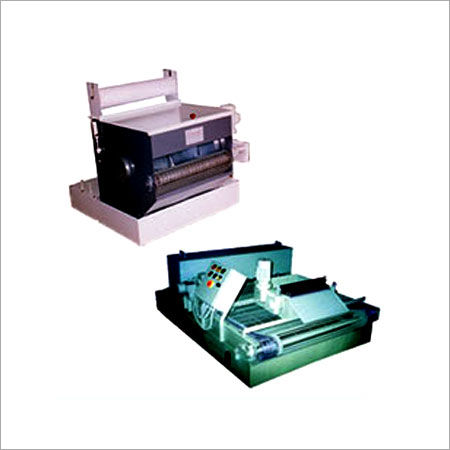

II. Paper Band Filtration System:

Paper Band Filtration System clarifiers offer the excellent means of filtering both ferrous and nonferrous particles. Where high degree of purification is required and contaminates differ in form size and composition paper band filtering are recommended for Grinding Honing Transfer lines and machining centre. It also can be used for rolling mills for filtering coolant which helps to improve the surface finish of the sheets.

Company Details

J.V.ENGG & CONVEYORS PVT LTD offers a comprehensive range of Bright Bar Machines i.e. Combine Drawing Machine High-speed Bar Peeling Machine Vertical Two Roll Straightening machine Horizontal Straightening machine De Coiler ( 90 Degree Tilting) & bar auto loading/Un Loading tables for various process. We founded our company in 2002 and immediately began working with clients in a variety of industries globally. As a customer-centric and technology-driven organisation our strength is in providing high-quality products and services. By regularly updating our technology and infrastructure we have been able to continue delivering high-value products to our customers.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

70

Establishment

2002

Working Days

Monday To Saturday

GST NO

06AABCJ3344E1ZZ

Payment Mode

Cheque

Certification

ISO 9001:2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 06AABCJ3344E1ZZ

Faridabad, Haryana

Director

Mr Sachin Panchal

Members since

22 Years

Address

Manufacturing Unit : Plot No. 23/25. 60 Ft. Road P.O. Pali -Sohna Road Vill. Nangla Gujran Faridabad Haryana 121004 India

Report incorrect details