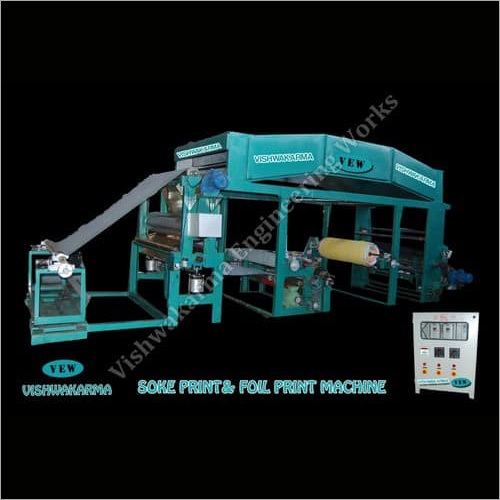

Fabric And Leather Hot Foil Stamping Bronzing Machine - 13600mm X 3800mm X 3900mm, 45kw Heating Power, Eco-friendly, High Efficiency, User-friendly Plc Control System, Low Noise, Customized Color Options

Price Trend: 40000.00 - 68900.00 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| General Use | Hot Foil Stamping for Fabric/Leather |

| Material | Other |

| Weight (kg) | 10000 Kilograms (kg) |

| Computerized | Yes |

| Automatic | Yes |

| Control System | PLC Control |

| Stamping Speed | 5-50m/min m/m |

| Stamping Temperature | 120a,,f Celsius (oC) |

| Power Consumption | 65KW Kilowatt (kW) |

| Plate Type | Hot Stamping |

| WorkingÃÂ Speed | 5-50 |

| Working Temperature | -10a,,f~40a,,f Celsius (oC) |

| Heating Power | 45KW Kilowatt (kW) |

| Voltage | 380V/220V/Customized Watt (w) |

| Dimension(L*W*H) | 13600mm x 3800mm x 3900mm Millimeter (mm) |

| Feature | Lower Energy Consumption, High Performance, ECO Friendly, Low Noise, High Efficiency |

| Color | Customized |

| Warranty | 12 Months |

| Payment Terms | Western Union, Paypal, Others, Telegraphic Transfer (T/T) |

| Delivery Time | 1 Week |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Export Market(s) | Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Africa, Asia |

Product Overview

Key Features

Application:

The machine is suitable for bronzing, single printing, pressing on the surface of various kinds of cotton, linen, silk, blended and knitted fabrics; and can also be used as a wrinkle fabric of gluing and laminating. Suitable for mass production of broad-band bronzing products, like home textiles, leather color changing, etc.

Two Bronzing Technology

Special Bronzing:

Cloth feeding----Gluing of printing roller----Pre-drying----Hot pressing and laminating of bronzing film----Cloth and film separation----The finished products rewinding

General Bronzing:

Bronzing film feeding----Gluing of printing roller----drying in the bridge type oven----cloth feeding, heat pressing and laminating----The finished products rewinding----thermal room----Cloth and film separator

Features:

1. Left and right movable blade is equipped to effectively protect the blade as well as the engraved roller, also to guarantee great bronzing/stamping effect.

2. High efficient heating tunnel with air circulating makes sure the heating even, fast speed, energy saving, and great effect.

3. The unwinding device with constant tension control system ensures the material in a tight state. Equipped with manual adjustment device to keep the material run in the correct way.

4. Using oil heated silicone roller with large contact surface and hydraulic press units, conducting a more stable and consistent pressure on material to ensure the bronzing effect.

5. Equipped with winding device both in front of and at the back of the machine, making a high applicable, easy and compact winding.

6. User friendly operation system is designed to make it easy to get in.

Company Details

Business Type

Exporter, Manufacturer

Employee Count

50

Establishment

2014

Working Days

Monday To Sunday

Payment Mode

Others

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Yancheng, Jiangsu

Sales Manager

Mr Miguel Wang

Address

No.1, East Chengxiang Road, Dagang Town, Yancheng, Jiangsu, 224043, China

hot foil stamping machine in Yancheng

Report incorrect details