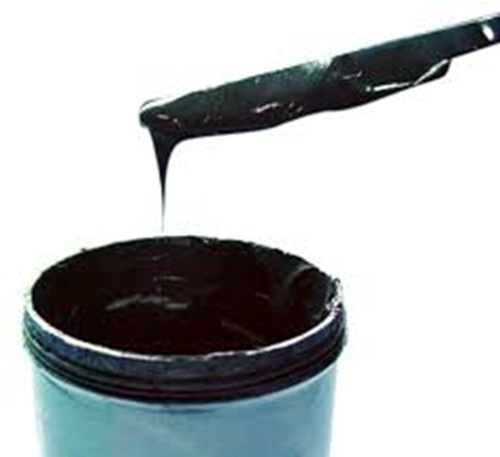

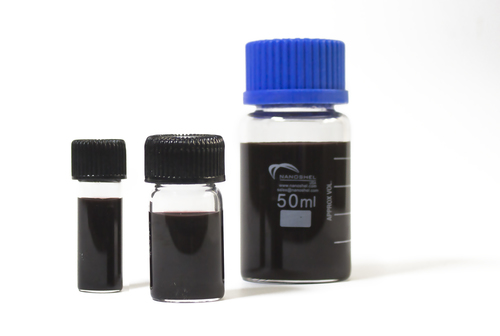

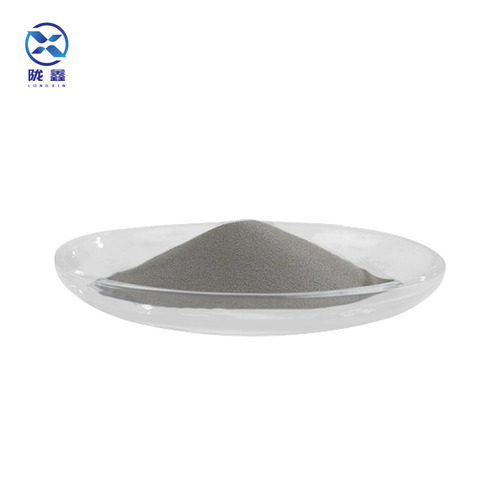

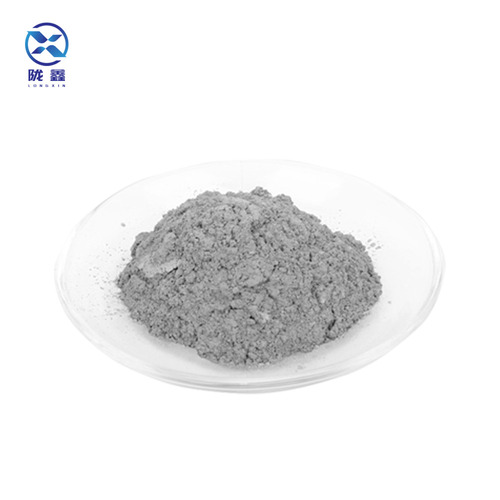

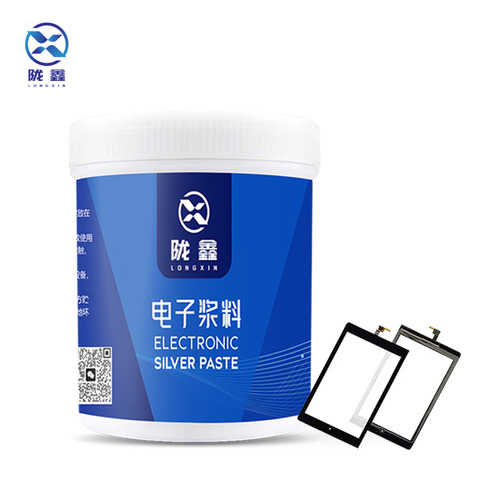

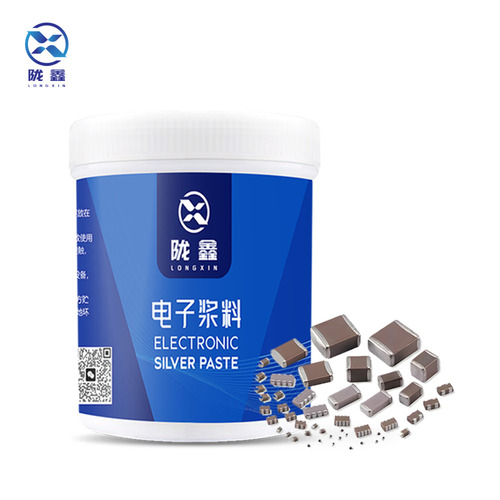

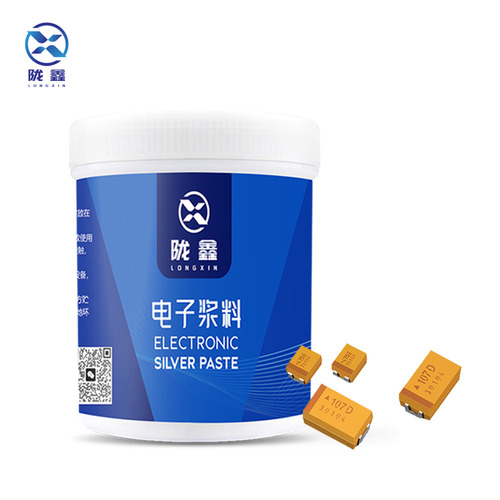

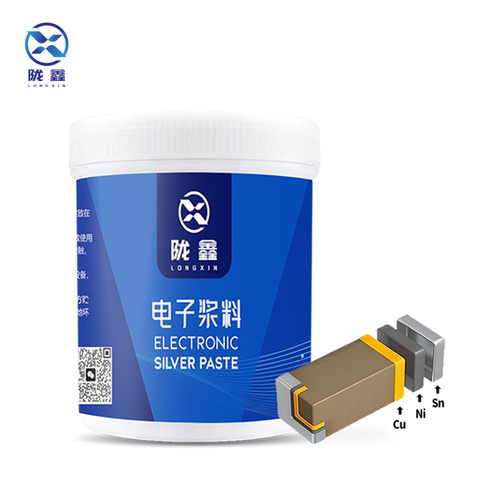

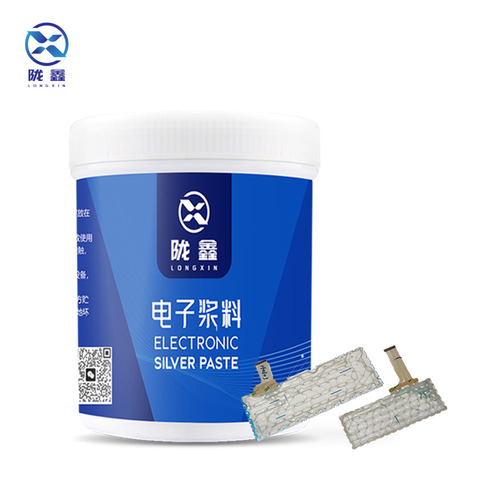

Excellent Bending Resistance Electronic Paste Low Temperature Curing Slurry Flexible Circuit Silver Paste

Price: 0.61 USD / Gram

Get Latest Price

Minimum Order Quantity :

100 Gram

In Stock

Product Specifications

| Storage Temperature | 25 Celsius (oC) |

| Types Of Chemical | silver |

| Adhesive Type | Other |

| Material | Other |

| Shelf Life | 6 Months |

| Surface Of Application | electronic conductive |

| CAS No | 7440-22-4 |

| Other Names | Silver ink |

| Grade | High |

| Purity | 53% |

| Application | Screen printing, polyester mesh or stainless steel mesh |

| Color | silver gray |

| Physical State | Other |

| FOB Port | SHUNDE |

| Payment Terms | Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C) |

| Supply Ability | 100000 Per Day |

| Delivery Time | 3 Days |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | 1kg/barrel |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa |

| Certifications | ISO9001, SGS, REACH, ROHS |

Product Overview

Key Features

Key attributes

CAS No.

7440-22-4

Place of Origin

Guangdong, China

Other Names

Flexible circuit silver paste

Grade Standard

Industrial Grade, Electron Grade

Application

Flexible circuit

Brand Name

LONGXIN

Model Number

LX-LMP4101

Solid content(%)

53A 1.0

Viscosity (dPa.s)

130A 50

Fineness(I m)

a 9

Square resistance(mIC/sq/mil)

a 10

Curing conditions

1st:Tunnel furnace: 135a *6 min,2nd:Oven: 135a *40 min

Process recommendation

Screen printing, polyester mesh or stainless steel mesh (250 mesh)

Packaging and delivery

Selling Units

Single item

Products Description

Model

LX-LMP4101

Solid contenti %i

53A 1.0

Viscosity (dPa.s)

130A 50

Finenessi I mi

a 9

Square resistance(mIC/sq/mil)

a 10

Curing conditions

1sti Tunnel furnace: 135a *6 mini 2ndi Oven: 135a *40 min

Process recommendation

Screen printing, polyester mesh or stainless steel mesh (250 mesh)

FAQ

1.How many days is the price valid for?

The price is valid for one day due to daily fluctuations in silver price. Please consult the salesperson for the exact price.

2. How should the conductive paste be stored?

a. Short-term storage. Seal and place at room temperature within 3-5 days.

b. For long-term storage, sintering slurry (sintering temperature above 400A C) can be stored at room temperature below 25A C, and stored in a refrigerator when the room temperature is higher than 25A C.

c. Quick-drying slurry and low-temperature curing slurry (below 200A C) can be stored in a refrigerator at 5~15A C.

d. Regardless any type of slurry, remember to seal it during storage.

3. What are the precautions before using conductive paste?

a. Take it out half a day in advance to warm it up or preheat it in a ventilated oven at 25~30A C for 20 minutes.

b. Do not open it before it returns to room temperature to prevent water vapor from cooling into the paste.

4. What should be paid attention to when using the conductive paste?

a. Make sure the paste is consistent with the ambient temperature.

b. Stir it thoroughly before use to restore the performance of the paste.

5. Do we need to add diluent when using conductive paste?

a. Generally, the viscosity of the paste is adjusted before leaving the factory, so it can be used directly after fully stirring without adding diluent

b. If it is necessary to add due to the process, such as increasing fluidity, spraying process, etc., add small amounts gradually and stir thoroughly. Do not add too much at one time.

c. Please use special diluents and do not mix them to cause performance changes.

CAS No.

7440-22-4

Place of Origin

Guangdong, China

Other Names

Flexible circuit silver paste

Grade Standard

Industrial Grade, Electron Grade

Application

Flexible circuit

Brand Name

LONGXIN

Model Number

LX-LMP4101

Solid content(%)

53A 1.0

Viscosity (dPa.s)

130A 50

Fineness(I m)

a 9

Square resistance(mIC/sq/mil)

a 10

Curing conditions

1st:Tunnel furnace: 135a *6 min,2nd:Oven: 135a *40 min

Process recommendation

Screen printing, polyester mesh or stainless steel mesh (250 mesh)

Packaging and delivery

Selling Units

Single item

Products Description

Model

LX-LMP4101

Solid contenti %i

53A 1.0

Viscosity (dPa.s)

130A 50

Finenessi I mi

a 9

Square resistance(mIC/sq/mil)

a 10

Curing conditions

1sti Tunnel furnace: 135a *6 mini 2ndi Oven: 135a *40 min

Process recommendation

Screen printing, polyester mesh or stainless steel mesh (250 mesh)

FAQ

1.How many days is the price valid for?

The price is valid for one day due to daily fluctuations in silver price. Please consult the salesperson for the exact price.

2. How should the conductive paste be stored?

a. Short-term storage. Seal and place at room temperature within 3-5 days.

b. For long-term storage, sintering slurry (sintering temperature above 400A C) can be stored at room temperature below 25A C, and stored in a refrigerator when the room temperature is higher than 25A C.

c. Quick-drying slurry and low-temperature curing slurry (below 200A C) can be stored in a refrigerator at 5~15A C.

d. Regardless any type of slurry, remember to seal it during storage.

3. What are the precautions before using conductive paste?

a. Take it out half a day in advance to warm it up or preheat it in a ventilated oven at 25~30A C for 20 minutes.

b. Do not open it before it returns to room temperature to prevent water vapor from cooling into the paste.

4. What should be paid attention to when using the conductive paste?

a. Make sure the paste is consistent with the ambient temperature.

b. Stir it thoroughly before use to restore the performance of the paste.

5. Do we need to add diluent when using conductive paste?

a. Generally, the viscosity of the paste is adjusted before leaving the factory, so it can be used directly after fully stirring without adding diluent

b. If it is necessary to add due to the process, such as increasing fluidity, spraying process, etc., add small amounts gradually and stir thoroughly. Do not add too much at one time.

c. Please use special diluents and do not mix them to cause performance changes.

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Foshan, Guangdong

Sivvy Leung

Address

null Foshan, Guangdong, China

Report incorrect details