Environment-friendly Fr Masterbatch - Hbcd Free, 55-65% Bromine Content, White Granules | Enhanced Flame Retardancy, Improved Compressive Strength, Superior Smoke Suppression Performance

Price:

Get Latest Price

In Stock

Product Specifications

| Application | Industrial |

| Shape | Granules |

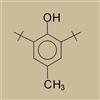

| Usage | This product is mainly used for Polystyrene foams, especially for extruded foamed Polystyrene (XPS), which is used in external thermal insulation system. As the substitute for traditional HBCD FR masterbatch, it is produced by the environment-friendly bromine-phosphorous FR , polystyrene as the carrier resin, flame retardant synergistic agent, small molecule capture agent and macromolecular chain-extender agent and other auxiliaries compound. Otherwise, it can give the sheets more excellent comprehensive performances than HBCD masterbatch. |

| Properties | AdvantageGood smoke-suppression performance. It can make smoke density reduce about 30%.Improve melt`s viscosity and strength, and then improve the compressive strength of the foams and provide better mechanical properties. Technical data sheet Items analysis resultappearance white granularbromine content% 55-65Volatile % 0.3 maxTG 5% 280 pH 6.5-8.5 |

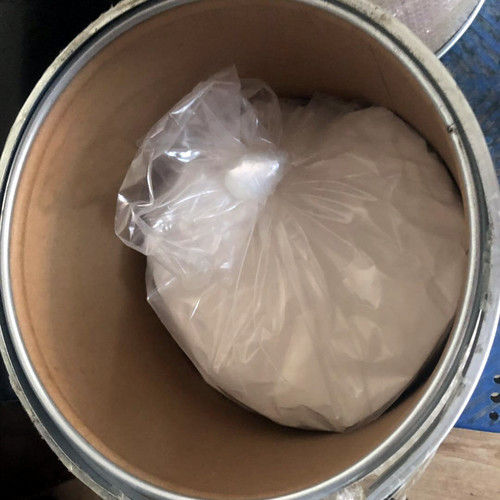

| Appearance | white granules |

| Storage | Room Temperature |

| Purity | 55%~65% bromine content |

| Grade | Industrial Grade |

| FOB Port | Qingdao |

| Payment Terms | Letter of Credit (L/C), Telegraphic Transfer (T/T) |

| Supply Ability | 1000 tons Per Month |

| Delivery Time | 15 Days |

| Sample Available | Yes |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Packaging Details | 25kg pp bag |

| Main Export Market(s) | North America, South America, Middle East, Africa, Asia |

| Main Domestic Market | All India |

Product Overview

Key Features

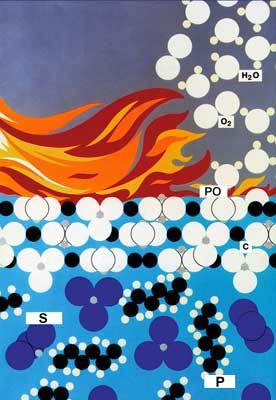

This polybrominated flame retardants masterbatch retardant using GPPS plastic as dispersion resin and

carrier,achieved with the XPS board seamless compatibility, easier to produce a good flame-retardant effect, small sheet density , smooth surface, high compressive strength of the flame extruded board. The production process of flame retardant extruded board is very easy to grasp.

Brominated flame retardants have efficient flame retardant effect, compared to HBCD flame retardant, it can be reduced by 30% -50% of the flame retardant amount but remains unchanged effect, the decrease in the content of the flame retardant have not brings lower effect, but also more stable production can be to achieve in the state of low grade flame retardant load requirements XPS, reducing the cost of flame retardants used at the same time and also make the density of extruded board lower and the sheet surface better.

Company Details

Focusing on a customer-centric approach, HEBEI FIZA TECHNOLOGY CO., LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Masterbatches in bulk from HEBEI FIZA TECHNOLOGY CO., LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Shijiazhuang, Hebei

Selina Xu

Address

Zhongyuan Building,Youyi North Street, Shijiazhuang, Hebei, China

flame retardant chemical in Shijiazhuang

Report incorrect details