Emulsion Polymerization Set-up Apparatus

Price: 1000.00 INR / Piece

(1000.00 INR + 0% GST)

Get Latest Price

1 Pack Contains :

1

Minimum Pack Size :

60

In Stock

Product Specifications

| Product Type | EMULSION POLYMERIZATION SET-UP APPARATUS |

| Usage | Chemical Engineering Laboratory Equipments |

| Application | Chemical Engineering Laboratory Equipments |

| Payment Terms | Cash Advance (CA) Cash in Advance (CID) Cheque Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Letter of Credit (L/C) |

| Packaging Details | carton box export quality also available |

| Main Export Market(s) | Asia Middle East Africa |

| Main Domestic Market | All India |

| Certifications | ISO 9001 14001 CE |

| Unit Type | Piece/Pieces |

| Packsize | 1 |

| Stock Quantity | 300 |

| Mop | 60 |

| Price | 1000.00 INR (Approx.) |

| Brand Name | Teknik |

| Price Type | fixed |

| Moq | 60 |

| Currency | INR |

| Returnable | No |

| Product Unit | 60 Piece/Pieces |

| Minimum Ordered Packs | 60 |

| Minimum Order Quantity | 60 |

| GSTIN | 0% |

Product Overview

Key Features

The emulsion is of the type: oil in water the monomer is oil soluble & the initiator is water-soluble & an emulsifier is used to create a stable emulsion.

Apparatus can be used to generate the kinetic data for emulsion polymerization under various operating conditions like temperature emulsifier concentration etc.

Polymerization is carried out under the atmosphere of air-free nitrogen. The set-up consists of a jacketed type SS reactor fitted with a variable speed agitator & baffles.

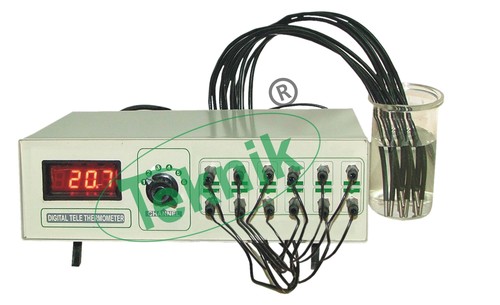

Hot water from a digitally controlled water bath is circulated in the jacket using a pump.

Metered quantity of nitrogen gas from a cylinder passes through a de-oxygenation column & allowed to enter the reactor.

Air has to be evacuated using a vacuum pump to create a vacuum of up to 30mm of Hg before passing the nitrogen supply.

Initiator from the reservoir is supplied to the reactor under pressure. Set-up is complete & self-contained with sampling ports

Experimentation/Learning Objectives:

The parameter studies are conducted involving studies of

Effect of RPM on conversion.

Effect of Initiator concentration.

Effect of monomer concentration

Effect of emulsifier concentration.

Utilities Required

The parameter studies are conducted involving studies of

Effect of RPM on conversion.

Effect of Initiator concentration.

Effect of monomer concentration

Effect of emulsifier concentration.

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

25

Establishment

1973

Working Days

Monday To Saturday

GST NO

06ACMPJ7244B1ZS

Certification

ISO 9001 : 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 06ACMPJ7244B1ZS

Ambala Cantt, Haryana

Ceo

Mr Vikas Jain

Members since

13 Years

Address

Plot No. 73 Vikaspuri Industrial Area Ambala Cantt Haryana 133001 India

chemical reactors in Ambala Cantt

Report incorrect details