Dye Penetrant Testing Service - Precision Method For Detecting Surface Defects In Non-porous Materials, Reliable Inspection For Quality Assurance

Price:

Get Latest Price

In Stock

Product Specifications

| Method | Dye Penetrant |

| Materials | Metals, Plastics |

| Sensitivity | High |

| Standards | ASTM E165 |

| Accuracy | High |

| Usage | Detects surface flaws in various materials like cracks, porosity, and leaks. |

| Report | Available |

| Features | Defect Detection, Surface Inspection, Cost-Effective, Reliable Results, Widely Applicable |

| Supply Ability | All Over The India Per Day |

| Delivery Time | Immediately Hours |

| Sample Available | Yes |

| Sample Policy | Free samples are available |

| Main Export Market(s) | Asia |

Product Overview

Key Features

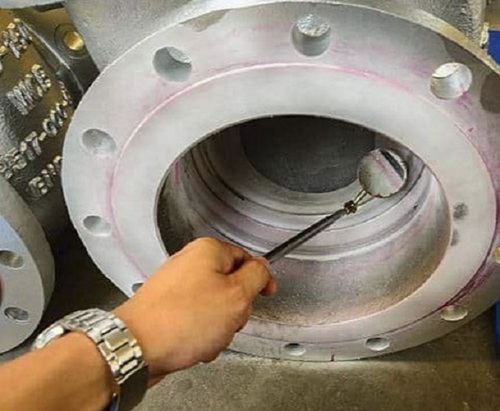

Dye penetrant inspection (DPI), also called liquid penetrant inspection (LPI) or penetrant testing (PT), is a widely applied and low-cost inspection method used to locate surface-breaking defects in all non-porous materials (metals, plastics, or ceramics). The penetrant may be applied to all non-ferrous materials and ferrous materials, although for ferrous components magnetic-particle inspection is often used instead for its subsurface detection capability. LPI is used to detect casting, forging and welding surface defects such as hairline cracks, surface porosity, leaks in new products, and fatigue cracks on in-service components.

DPI is based upon capillary action, where low surface tension fluid penetrates into clean and dry surface-breaking discontinuities. Penetrant may be applied to the test component by dipping, spraying, or brushing. After adequate penetration time has been allowed, the excess penetrant is removed and a developer is applied. The developer helps to draw penetrant out of the flaw so that an invisible indication becomes visible to the inspector. Inspection is performed under ultraviolet or white light, depending on the type of dye used - fluorescent or non fluorescent (visible).

Company Details

Focusing on a customer-centric approach, CR Quality & Engg. Services has a pan-India presence and caters to a huge consumer base throughout the country. Get Analytical Testing Laboratories from CR Quality & Engg. Services at Trade India quality-assured services.

Business Type

Service Provider

Establishment

2016

More Product From This seller

Seller Details

Pune Cantonment, Maharashtra

Proprietor

Mr. Chetan Arun Rekhate

Address

4th Floor, Ford Fatak, Kedar Empire, Near Bashuja Company, Pune Cantonment, Maharashtra, 411038, India

ndt services in Pune Cantonment

Report incorrect details