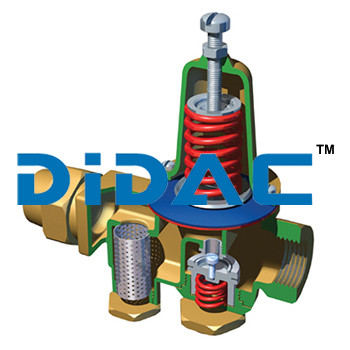

Dual Setting Pressure Reducing Valve

Price:

Get Latest Price

In Stock

Product Specifications

| Valve Size | 50-1000 |

| Pattern & Size | Y-Type |

| Screwed | 238 mm |

| 10kgf/cm2 | 238 mm |

| Weight | 14 kgs |

| Material | Approved raw |

| Model | 132-070 |

| Features | Easy installation, Rugged design, Corrosion resistance, Long life, Sturdy structure, Low consumption, Unmatched performance |

Product Overview

Key Features

Backed by a competent team of professionals, we have been able to manufacture, export and supply supreme quality Dual Setting Pressure Reducing Valve that finds its main application in power stations, thermal power plants, oil drilling, etc. The valve provided by us is manufactured at our well-developed production unit, equipped with sophisticated technology and machines using quality approved raw material. Apart from this, our clients can avail this Dual Setting Pressure Reducing Valve from us in various sizes and other related specifications at most affordable price.

Features:

-

Our quality professionals check these pressure reducing valves on varied parameters to ensure hassle free working

-

These pressure reducing valves are preferred for their easy installation and have rugged design

-

Our pressure reducing valves are known for their corrosion resistance and are easy to use

-

These pressure reducing valves have long operational life and have sturdy structure

-

Acknowledged by the customers for their low power consumption, unmatched performance and accurate pressure control

Model 132-070 have 3-way solenoid valves, two pressure reducing pilot valves and robocon valves (Balem 130). Offered pressure reducing valves have one pilot set a higher pressure for high water demand and a second pilot set at lower pressure for lower water demand. Furthermore, our pressure reducing valves require electric power source and control system to change the time according to the change in the rate of flow of the solenoid valve.

Dimensions:

[BALEM 130 - Up-right Globe & Angle Type ]

| (mm) | |||||||

| Valve Size | 50 | 80 | 100 | 150 | 200 | 250 | 300 |

| A(Screwed) | 238 | 318 | - | - | - | - | - |

| AA(10kgf/cm2) | 238 | 305 | 381 | 508 | 645 | 756 | 864 |

| B | 78 | 93 | 105 | 140 | 165 | 200 | 223 |

| C(max) | 200 | 240 | 275 | 375 | 470 | 535 | 625 |

| D(max) | 157 | 179 | 206 | 284 | 360 | 420 | 465 |

| E | 140 | 165 | 208 | 326 | 408 | 497 | 562 |

| F(Screwed) | 119 | 140 | - | - | - | - | - |

| FF(10kgf/cm2) | 119 | 152 | 191 | 254 | 322 | 378 | 432 |

| G(Screwed) | 83 | 114 | - | - | - | - | - |

| GG(10kgf/cm2) | 83 | 102 | 127 | 152 | 203 | 219 | 349 |

| Weight(kgs) | 14 | 26 | 41 | 95 | 169 | 268 | 492 |

When you order, please must check "How to Order" in ROBOCON valve!

| (inches) | |||||||

| Valve Size | 2 | 3 | 4 | 6 | 8 | 10 | 12 |

| A(Screwed) | 9.38 | 12.50 | - | - | - | - | - |

| AA(150 ANSI) | 9.38 | 12.00 | 15.00 | 20.00 | 25.38 | 29.75 | 34.00 |

| B | 3.00 | 3.75 | 4.50 | 5.50 | 6.75 | 8.00 | 9.70 |

| C(max) | 7.88 | 9.45 | 10.83 | 14.77 | 18.43 | 20.95 | 24.53 |

| D(max) | 6.19 | 7.05 | 8.12 | 11.19 | 14.14 | 14.46 | 18.15 |

| E | 5.52 | 6.50 | 8.19 | 12.83 | 16.07 | 19.57 | 22.13 |

| F(Screwed) | 4.69 | 6.25 | - | - | - | - | - |

| FF(150 ANSI) | 4.69 | 6.00 | 7.50 | 10.00 | 12.69 | 14.88 | 17.00 |

| G(Screwed) | 3.25 | 4.50 | - | - | - | - | - |

| GG(150 ANSI) | 3.25 | 4.00 | 5.00 | 6.00 | 8.00 | 8.62 | 13.75 |

| Weight(lbs) | 31 | 57 | 90 | 210 | 373 | 591 | 1,085 |

BALEM 130 - Y-Type Globe

| Valve Size | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| L 10,20kgf/cm2 | 205 | 230 | 270 | 310 | 375 | 430 | 520 | 610 | 700 | 730 | 910 | 1010 | 1200 | 1400 | 1480 | 1650 | 1800 |

| H1 | 77.5 | 87.5 | 100 | 110 | 125 | 142.5 | 175 | 205 | 230 | 265 | 300 | 380 | 420 | 500 | 565 | 590 | 640 |

| H2 | 176 | 199 | 221 | 250 | 313 | 343 | 441 | 519 | 615 | 629 | 753 | 893 | 1030 | 1255 | 1412 | 1461 | 1584 |

| E | 135 | 154 | 180 | 220 | 260 | 305 | 380 | 455 | 545 | 545 | 705 | 794 | 934 | 1160 | 1215 | 1315 | 1400 |

Pattern & Size

| Pattern & Size | Up-right Globe / Angle Type | Y-Type Globe |

| 50 ~ 300A | 50 ~ 1000A | |

| Operating Pressure | 10kgf/cm2, 16kgf/cm2, 20kgf/cm2, 25kgf/cm2 | |

| Media | Water, Oil Temperature : 0oC ~ 80oC | |

| End Connection | According to Customer Request | |

Materials

| Components | Materials | ||

| Standard | Optional | ||

| 50A~300A | 400A~1000A | ||

| Body & Cover | Ductile Iron | Cast Steel | SSC13 |

| Diaphragm Washer & Disc | Ductile Iron | Cast Steel | SSC13 |

| Cover Plug & Bearing | SSC13 | ||

| Shaft & Seat | STS304 | ||

| Diaphragm | N.R/C.R/N.B.R | ||

| Disc Seal | N.R/C.R/N.B.R | ||

Note

- NSF/ANSI Standard 61 Epoxy Coating Standard

- Nylon 11 Coating available(Rilsan Coating) : Optional

Company Details

Focusing on a customer-centric approach, BALEM CO., LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Control Valves in bulk from BALEM CO., LTD. at Trade India quality-assured products.

Business Type

Exporter

Employee Count

35

Establishment

1981

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Busan, Busan

Clerk

Ms. Kang Hye Min

Address

#46, Noksansaneopjung-ro, Gangseo-gu, Busan, Busan, 618-817, Korea South

pressure reducing valves in Busan

Report incorrect details