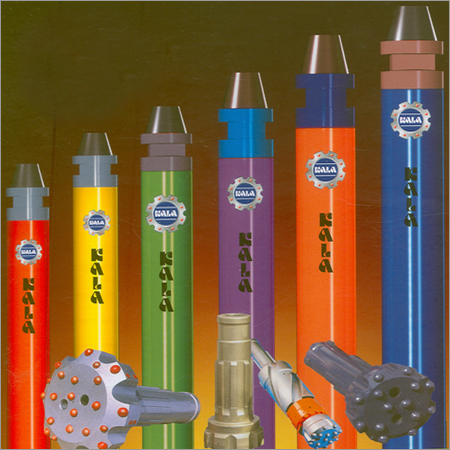

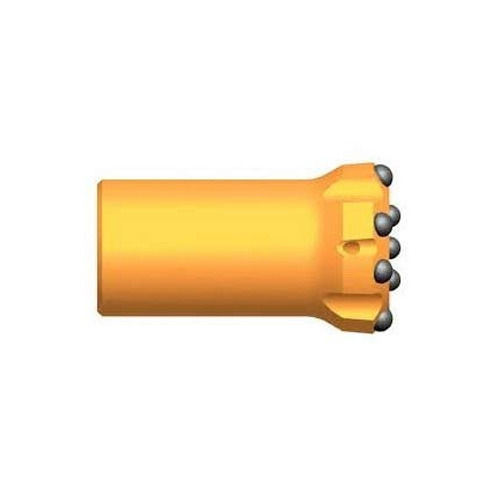

Dth Hammer Button Bit - Carbon Steel, Multiple Sizes, Grey Color | High Efficiency, Durable Design For Optimal Drilling Performance

Price:

Get Latest Price

In Stock

Product Specifications

| Size | Multiple |

| Color | Grey |

| Product Type | DTH Hammer Button Bit |

| Usage | Drilling Use |

| Tool Type | Drilling Use |

| Material | Carbon Steel |

| Shape | Round |

| Supply Ability | 100 Per Day |

| Delivery Time | 10 Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Box |

| Main Domestic Market | All India |

Product Overview

Key Features

- DTH hammers operate on the principle of compressed air or other gases driving a piston inside the hammer body. The piston strikes the back of the drill bit, transferring energy and breaking the rock formation.

2. **Design:**

- DTH hammers typically consist of a hammer body, piston, and bit shank. The hammer body contains the piston and guides the airflow. The piston strikes the drill bit, which is attached to the bit shank.

3. **Bit Shank Connection:**

- DTH hammers use various types of bit shank connections, including standard API connections or proprietary designs specific to the manufacturer. The bit shank connects the hammer to the drill bit.

4. **Size and Weight:**

- DTH hammers come in various sizes and weights to accommodate different drilling applications and rock formations. Larger hammers are used for heavy-duty drilling in hard rock, while smaller hammers are suitable for lighter applications.

5. **Drilling Efficiency:**

- DTH hammers are known for their high drilling efficiency, allowing for fast penetration rates in various geological formations. The impact force generated by the hammer results in efficient rock breaking and removal.

6. **Hammer Types:**

- There are different types of DTH hammers available, including valveless hammers, valve-equipped hammers, and reverse circulation hammers. Each type has specific advantages and is chosen based on the drilling requirements and conditions.

7. **Pressure and Air Flow Requirements:**

- DTH hammers require a consistent supply of compressed air or gas to operate effectively. The pressure and flow rate of the air/gas must be optimized for the specific hammer size and drilling conditions.

8. **Durability and Maintenance:**

- DTH hammers are subjected to high levels of stress and wear during drilling operations. Therefore, they are designed to be durable and resistant to abrasion and impact. Regular maintenance, including inspection and replacement of worn components, is essential for optimal performance and longevity.

9. **Compatibility with Drill Rigs:**

- DTH hammers must be compatible with the drill rig being used for the drilling operation. Factors such as connection type, size, and operating parameters must be considered to ensure seamless integration and efficient drilling.

10. **Cost and Quality:**

- DTH hammers vary in cost depending on factors such as size, brand, and quality. While cost is a consideration, investing in high-quality hammers from reputable manufacturers can result in better performance and longer service life.

DTH hammers play a crucial role in various drilling applications, and selecting the right hammer for the job is essential for achieving optimal drilling performance and efficiency. Factors such as rock hardness, drilling depth, and project requirements should be carefully evaluated when choosing a DTH hammer for a specific application.

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Distributor, Supplier, Trading Company

Employee Count

50

Establishment

1987

Working Days

Monday To Sunday

GST NO

36AKEPP5822H1Z2

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 36AKEPP5822H1Z2

Hyderabad, Telangana

Proprietor

Mr Prakash

Address

Unit No. - 1,1,15/1, Near Old Kapra Municipal Office, Kapra Kushaiguda, Hyderabad, Telangana, 500062, India

dth hammer bit in Hyderabad

Report incorrect details