Dry Running Agitator Seal - Carbon/sic/tc Seal Faces, 15 To 100mm Diameter | High Vacuum Performance, No Auxiliary Equipment Required, Minimal Downtime

Price:

Get Latest Price

In Stock

Product Specifications

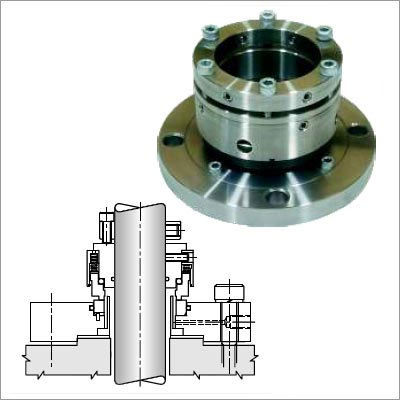

| Seal Faces | Carbon/Sic/Tc |

| Secondary Seals | Viton/Epr/Ptfe |

| Metal Seals | Ss-316/304 |

| Shaft Dia | 15 To 100Mm |

| Pressure | Up To 1.40 Mpa |

| Temperature | -20 To 120°C |

| Speed | Up To 1 M/S |

| Features | Rugged Design, Simple Drive, No Lubricants, High Vacuum, Easy Install, Low Cost, No Contamination, Minimizes Downtime |

Product Overview

Key Features

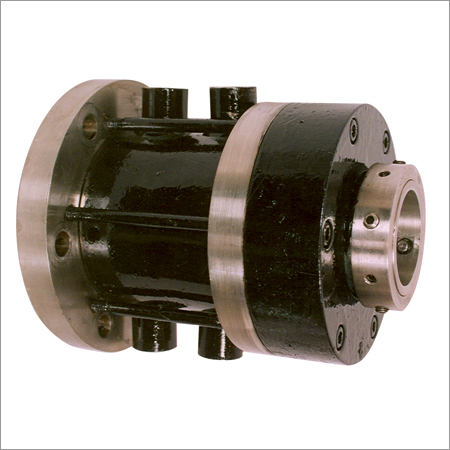

We are manufacturer, supplier and exporter of precision designed Dry Running Agitator Seal to our widely scattered clientele base. The offered seals are outside mounted balanced seal that need no sleeve or shaft step for the purpose of balancing FSI 101 seal shows excellent performance in high vacuum conditions. Offered seal doesn't need any auxiliary equipment for installation, due to which, it is very economical. Our provided Dry Running Agitator Seal can be easily placed and needed on the field to minimize replacement costs & downtime.

Features:

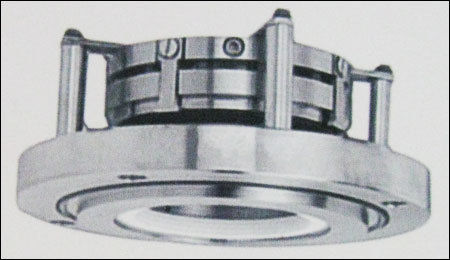

- Rugged, simple drive design that withstand shaft movement vibration & deflection.

- Seal design eliminates the need of auxiliary equipments for cooling and lubricants for mixer application.

- It eliminates the possibility of product contamination, Since there is no use of barrier fluid.

- Can be utilized in high vacuum applications.

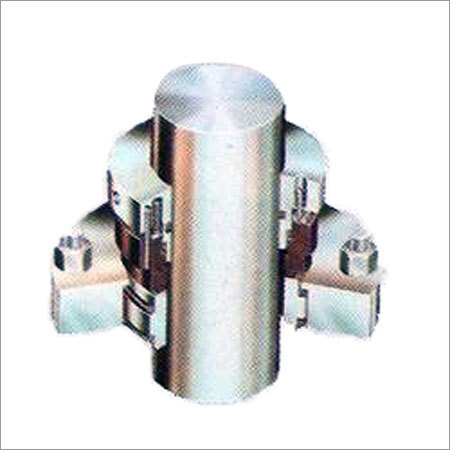

Seals alongwith bearing can be provided for vessels having greater misalignment with special arrangement.

Applications:

Used in top entry mixer vessels in chemical & pharmaceutical industries.

Material:

- Seal Faces: Carbon/Sic/TC

- Secondary Seals: Viton/EPR/PTFE/GFT/AFLAS/FFKM

- Metal Seals: SS-316/304

Operating Limits:

- Shaft Dia: 15 to 100mm

- Pressure: Up to 1.40 Mpa

- Temp. : -20 to 120oC

- Speed: Up to 1 m/s

Company Details

Business Type

Exporter, Importer, Manufacturer, Service Provider, Supplier, Trading Company

Employee Count

6

Establishment

1996

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Mumbai, Maharashtra

Proprietor

Mr. Asif Charolia

Address

Shafi Compound, Gala No. 8, Rahat Nager, Near Al-Falah Chs, Behram Baug, Jogeshwari (W), Mumbai, Maharashtra, 400102, India

agitator seals in Mumbai

Report incorrect details