Dry Bulk Liner - Pe & Pp Woven Materials | Enhanced Protection Against Contamination, Fast Installation, Increased Loading Capacity, Labor Cost Reduction

Price:

Get Latest Price

In Stock

Product Specifications

| Material | PE/PP |

| Color | Green |

| Capacity | Variable |

| Dimensions | Customizable |

| Usage | Dry bulk material transport within containers |

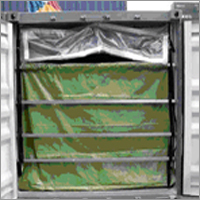

| Closure | Zipper/Tie |

| Compliance | ISO |

| Features | Product Protection, Cost Savings, Efficient Loading, Easy Disposal, Clean Transport |

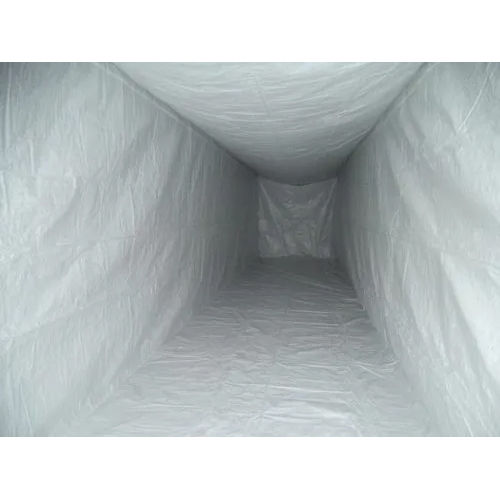

Product Overview

Key Features

Container Liner Applications : | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Liners are used for a wide and constantly growing range of granular and powder products as a highly effective and time saving alternative to sacks and bags. The following is merely an illustration of some of the products suitable for transportation in liners. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The advantages of dry bulk liners : | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| To protect products from conta-mination. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| * Contamination of products during unpacked times can be benefi-cially avoided. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| * Loading capacity of the Liners can be considerably increased. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| * Cuts down the normal Working hours and Labour costs drasti-cally. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| * Packing costs can be saved to the maximum extent. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| * Disposal cost and the cost of Packaging can be saved. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

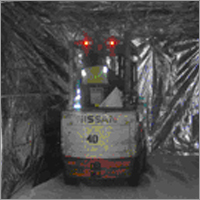

| * Fast installation of them is possi-ble and loading & discharge works can be accomplished quickly. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Container Liners protect products from contamination, apart from protecting the environment from pollution of.some products. Products are kept in a safe, clean and dry condition by enclosing them with their own disposable shell(s). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Company Details

Focusing on a customer-centric approach, SHAKTI RUBBER PRODUCTS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Packaging Bags in bulk from SHAKTI RUBBER PRODUCTS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

30

Establishment

2013

Working Days

Monday To Sunday

GST NO

29ADHPN0951F1ZJ

Payment Mode

Cash Advance (CA), Cash in Advance (CID), Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 29ADHPN0951F1ZJ

Bengaluru, Karnataka

Proprietor

Mr. Ramesh

Address

No.205/B, 12th Main Road, 3rd Phase, Peenya Industrial Area, Bengaluru, Karnataka, 560058, India

container liner in Bengaluru

Report incorrect details