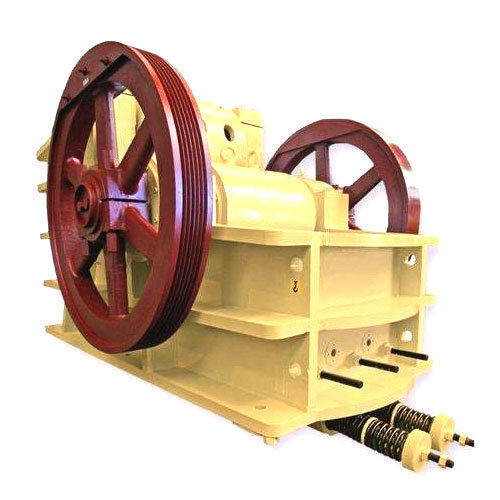

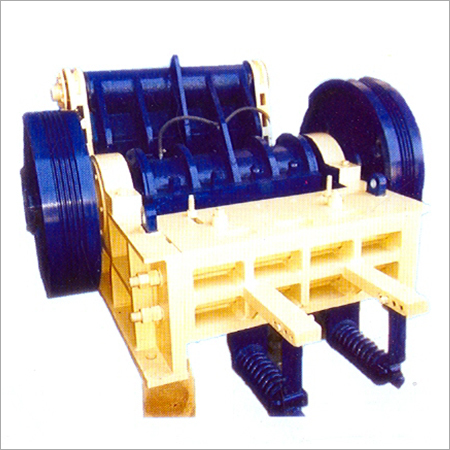

![Double Toggle Jaw Crusher [Oil Bath Type]](https://tiimg.tistatic.com/fp/2/005/845/double-toggle-jaw-crusher-oil-bath-type--216.jpg)

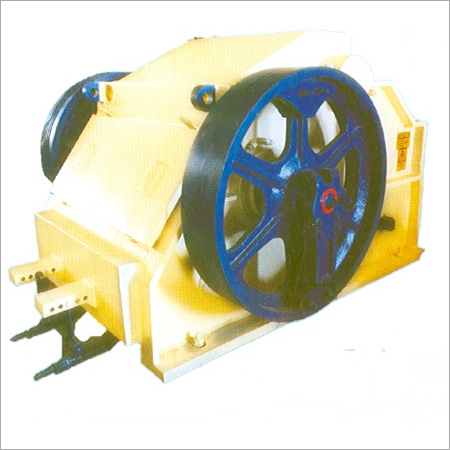

Double Toggle Jaw Crusher [Oil Bath Type]

Price:

Get Latest Price

In Stock

Product Specifications

| Jaw Type | Double Toggle |

| Lubrication | Oil bath |

| Material | Steel |

| Drive Type | Belt |

| Capacity | 10-174 TPH |

| Usage | Crushing hard rocks, ferroalloys, and glass |

| Safety | Overload protection |

| Features | High efficiency, Durable design, Precise control, Cost effective, Safe operation, Cubical product |

Product Overview

Key Features

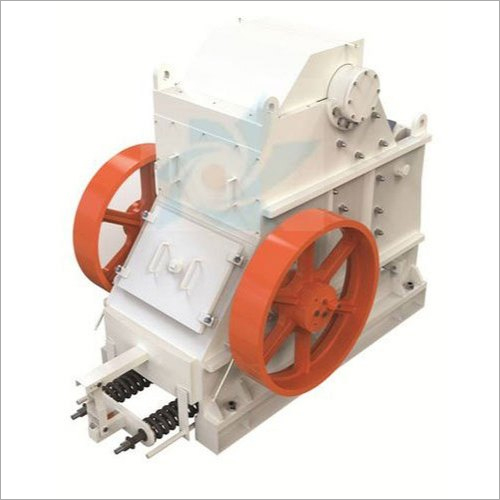

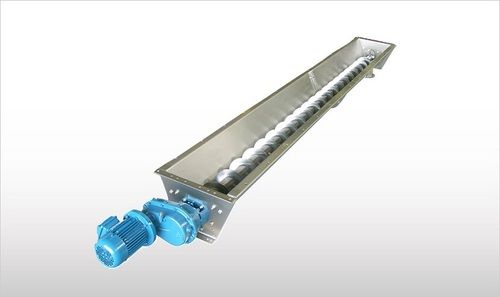

Double Toggle Jaw Crusher [Oil bath type]

Double

Toggle Jaw Crushers are preferred for crushing unusually hard,

abrasive rocks and other materials like ferroalloys and glass. They

differ substantially from other types of crushers. There is no rotary

motion in the crushing cycle and all crushing is done by compression

of the feed material between two massive jaw plates. The moving jaw

compresses the material against the stationary jaw. Jaw plates can be

either smooth or corrugated.

Working

Principle and Advantages

Double

Toggle Jaw crushers have one jaw fixed, while the other jaw

pivots about the top hinge. This moving jaw is shaped to move firmly

and squarely against the material. There is no rubbing or grinding,

purely compression, which produces a generally cubical product with

minimum fines. The moving Jaw is very well balanced, so 95% of the

drive motor power is used for crushing, while only 5% of the power is

needed to move the jaw itself. As a result of this high mechanical

efficiency, Double Toggle Jaw crushers require smaller size motors,

keeping power costs down. Behind the stationary jaw are shims, used

to adjust the distance between the lower ends of the jaws (closed

side setting). This setting determines the output product size. There

is also an arrangement of safety arm for protection from uncrushables

or accidental overloads.

Crushing applications

of Double Toggle Jaw crusher

- Granite

- Lime stone

- Ferro alloys

- Black trap rocks

- Coal/Coke

- Carborundum

- River Gravel

- Iron Ore

- Emery

- Blast Furnace slag

- Manganese Ore

- Bauxite

- Cupriferous Slag

- Quartzite

- Calcium Carbide

Double Toggle Jaw

crusher capacity and power chart

[Capacities are based on

bulk density of 1.6 T/m3]

Jaw mm X mm | Maximum Feed MM | Capacities in TPH at closed side |

|

| |||||||||||||||

13 | 20 | 25 | 32 | 28 | 51 | 63 | 76 | 89 | 100 | 127 | |||||||||

300 X 175 | 138 | 6 | 7 | 8 | 10 | 13 | 18 | 25 | 375 | 10 | |||||||||

300 X 225 | 175 | 8 | 11 | 13 | 15 | 16 | 22 | 31 | 375 | 20 | |||||||||

500 X 300 | 250 | 13 | 16 | 19 | 22 | 30 | 38 | 45 | 375 | 40 | |||||||||

750 X 375 | 300 | 35 | 44 | 58 | 64 | 71 | 89 | 350 | 50 | ||||||||||

750 X 500 | 400 | 54 | 68 | 83 | 98 | 115 | 350 | 60 | |||||||||||

800 X 200 | 150 | 32 | 40 | 47 | 55 | 65 | 77 | 350 | 40 | ||||||||||

900 X 200 | 150 | 35 | 44 | 52 | 62 | 72 | 85 | 96 | 350 | 50 | |||||||||

900 X 500 | 400 | 75 | 80 | 84 | 98 | 115 | 350 | 60 | |||||||||||

900 X 600 | 500 | 84 | 111 | 125 | 138 | 174 | 350 | 75 | |||||||||||

Company Details

Focusing on a customer-centric approach, AMAR FABRICATORS & ENGINEERS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Mining, Exploration & Drilling Machinery in bulk from AMAR FABRICATORS & ENGINEERS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

16

Establishment

1984

Working Days

Monday To Sunday

GST NO

24AAKFA2119G1ZW

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AAKFA2119G1ZW

Ahmedabad, Gujarat

Exe. Engineer

Mr. Vikesh Patel

Address

No C-1/B, 4305, Phase-4, G.I.D.C, Vatva, Ahmedabad, Gujarat, 382445, India

double toggle jaw crusher in Ahmedabad

Report incorrect details