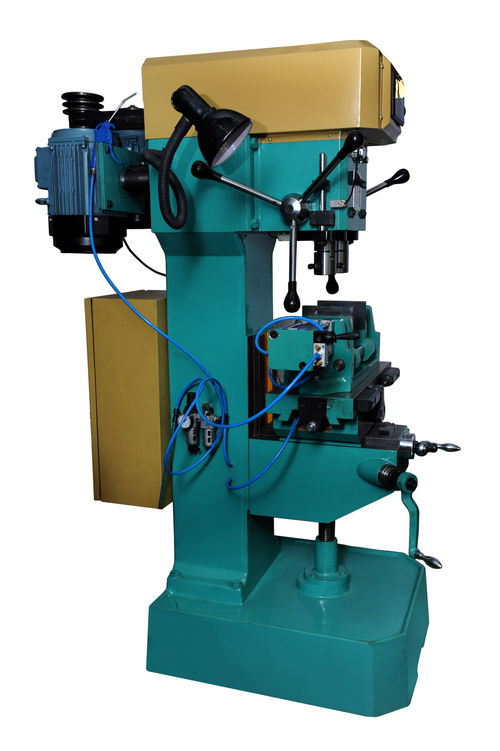

Double Spindle Tapping Machine - Pneumatic Slide Operation, 40mm Maximum Boring Diameter | High Efficiency, Easy Operation, Enhanced Service Life

Price:

Get Latest Price

In Stock

Product Specifications

| Max Boring Diameter | 40mm |

| Max Tapping Diameter | M36 |

| Spindle Motor (Turning) | 2HP |

| Spindle Motor (Tapping) | 3HP |

| Spindle Speed (Drilling) | 1040, 1330 rpm |

| Spindle Speed (Tapping) | 550, 860 rpm |

| Spindle Feed Travel | 160mm |

| Distance Between Spindles | 150mm |

| Distance Spindle Axis To Column | 206mm |

| Distance Spindle Face To Worktable | 400mm |

| Worktable Travel (Longitudinal) | 100mm |

| Worktable Travel (Transversal) | 280mm |

| Worktable Size | 600mm x 240mm |

| Features | High efficiency, Easy operation, Precise finish, Reduced cost, Long lifespan, Easy maintenance, Durable design, Versatile use |

Product Overview

Key Features

Since our establishment in the 1990, we are acknowledged as one of the leading manufacturers of Double Spindle Tapping Machine. These machines are suitable for tapping and reaming automotive parts, machine tools, plumbing valves, hardware tools and door locks. In order to design this Double Spindle Tapping Machine, our professionals use quality tested materials procured from the authentic vendors. Moreover, our machines are offered to the clients at pocket friendly prices.

Features:

- Rugged in design

- Easy to operate

- Enhanced service life

Further Details:

In this machine slide and work holding device are pneumatically operated. This machine is operated through a PLC panel. This machine can be applied in components processing in large quantity. The drilling and threading processing can be finishing once. Slide moving use with buffer, low vibrate, and adopts pneumatic clamp, loading and unloading rapidly.

Functions:

- Suit for drilling, reaming, turning and tapping in quantity production at one time.

- Boring and facing one time.

- Threading as per a required sized taps.

- Both the left and right of workbench adopt cylinder for minimal vibration.

- Machine's slide is pneumatically operated.

- Work holding device is pneumatically operated (uses cylinder)to hold the job for fast fixing.

- Machine operated through a plc panel.

- FRL is used for regulating the air and lubricant.

- Solenoid valve for controlling the pressure of slides for moving.

- Manual oil injector, manually feeding oil before and after the processing can maintain the machine in good condition.

- RED emergency button is given on the head cover or belt cover to stop all the operations in need or emergency.

Advantages:

- Increases the production efficiency by four to five times and reduce the manufacturing cost

- Easy operations on the control panel.

- It is capable of providing extra precision and finish with ease.

- No skilled operator is required to operate the machine.

- All sliding surfaces with lubrication device, ensuring high service life.

- Easy maintenance due to all parts available.

Applications:

- Applicable for processing parts of large batch, one-off drilling and threading extending high efficiency.

- Specially applicable for the rapid processing of the components used in the field of bathroom fittings or sanitary wares manufacturing.

- This machine can be applicable for the processing of the components used in the fields like automotive, tools, plumbing valves, hardware tools, door locks etc

Machine Specifications

| Maximum Boring Diameter | 40mm |

| Maximum Tapping Diameter | M36 G1 |

| Motor For Spindle(turning or reaming) | 2HP |

| Motor For Spindle(Tapping) | 3HP |

| Spindle Rotation Speed | |

| Drilling | 1040,1330 rpm |

| Tapping | 550, 860 rpm |

| Spindle Feed Travel | 160mm |

| Distance Between Spindles | 150mm |

| Distance From Spindle Axis To Column | 206mm |

| Distance From Spindle Face To Worktable | 400mm |

| Worktable Travel | |

| Longitudinal | 100mm |

| Transversal | 280mm |

| Worktable Size | 600mm x 240mm |

Company Details

Focusing on a customer-centric approach, INDIA MACHINE TOOLS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Pneumatic Products & Tools in bulk from INDIA MACHINE TOOLS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Distributor, Supplier

Employee Count

7

Establishment

1990

Working Days

Monday To Sunday

GST NO

07AAAPI4449M1ZJ

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AAAPI4449M1ZJ

Delhi, Delhi

Mr. Yahya Saifi

Address

L-21, Sector-5, Dsiidc, Bawana Industrial Area, Delhi, Delhi, 110039, India

pneumatic tapping machine in Delhi

Report incorrect details