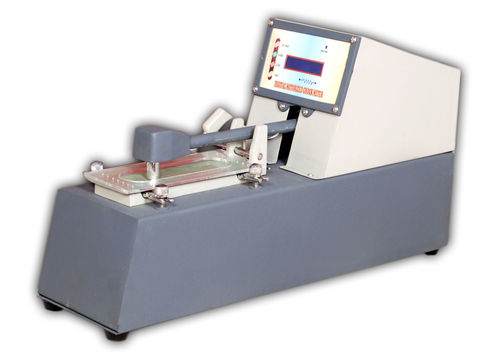

Digital Tensile Strength Testing Instruments

Price:

Get Latest Price

In Stock

Product Specifications

| Capacity | 500kg |

| Jaw Separation | 600mm |

| Traverse Speed | 500mm/min |

| Material | Metal |

| Color | Gray |

| Power | Electrical |

| Usage | Testing tensile strength and elongation of materials like rubber, leather, fabrics, plastics, and wires. |

| Features | Precise measurement, Durable design, Easy operation, Cost-effective, Versatile use |

Product Overview

Key Features

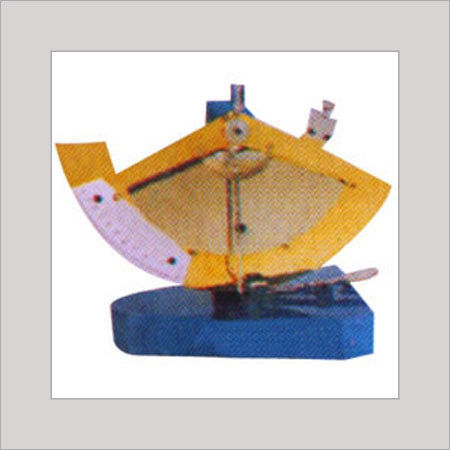

Digital Tensile Strength Tester:-

Capacity:-

- Force: 50/250/500 kilogram.

- Jaw separation: 0 to 600mm.

- Traverse speed: 50 to 500mm per minute.

Tensile Strength and elongation are the two prime characteristics of most of the raw materials, whether they are metals; or non-metals such as rubber, leather, textiles, plastic paper; or finished products such as rods, wires, ropes, yarns belts etc. These properties very often play the major role in determining the suitability of any raw material for any specific applications. It is, therefore of utmost importance to determine these characteristics accurately, conveniently, and quickly.

The Digital Tensile Strength Tester Machines provide a relatively inexpensive way for determining the tensile strength and elongation of a variety of raw materials such as rubber, leather, fabric, plastics, belts wires etc., They are based on constant rate of traverse principle in which one end of the test specimen is held in a and screw arrangement. The load exerted on the stationary grip is measured by a pendulum dynamometer, where the angular movement of the pendulum because of application of load is converted into the movement of a pointer on a calibrated circular dial indicating the load directly in kilograms or Newtons. A dummy pointer is provided to indicate the maximum load exerted by the test specimen before it fails. The load measurement range is sub divided into three or four sub ranges which can be attained by addition / removal of calibrated disc weights from the pendulum.

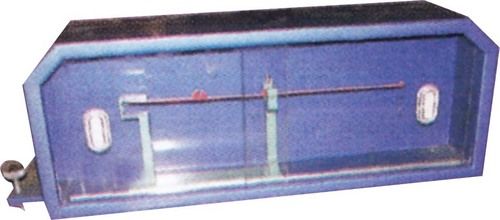

The elongation of the test specimen is measured on a linear scale fixed on the frame of the tester, which indicates the distance between the grips. Arrangement to plot the load versus elongation chart is available as an optional accessory.

Company Details

Focusing on a customer-centric approach, G. S. INSTRUMENTS CO. has a pan-India presence and caters to a huge consumer base throughout the country. Get Testing & Measuring Equipment from G. S. INSTRUMENTS CO. at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Establishment

1996

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

New Delhi, Delhi

Proprietor

Mr. Rajiv Gupta

Address

529, Krishna Mandir Marg, Nangloi, New Delhi, Delhi, 110041, India

Report incorrect details