Process Control Equipment & Instruments

(3120 products)Product Showcase

Air Flow Studies Apparatus - Application: Laboratory

By:

Didac International

SIEMENS SCADA 6AV2100-0AA02-3AH5

By:

Naksh Technology

Variable Speed Drives - Application: For Crane And Elevetor

By:

Mifa Systems Pvt. Ltd.

Weatherproof Loop Power Indicator (Lpi-400 Wp) - Accuracy: Linear : +/-0.1 Percent Of Span ; Square Root : +/-0.2 Percent Of Span %

5550 INR

By:

Ambetronics Engineers Pvt. Ltd.

Naksh Technology Solution Llp

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Premium Seller

Premium Seller8 Years

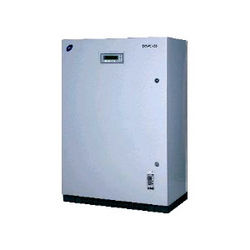

Variable Speed Drives - Application: For Crane And Elevetor

Price Trend: 13900.00 - 32200.00 INR/Unit

MOQ1 Unit/Units

Product TypeVFD

ApplicationFor Crane and Elevetor

Protection LevelIP55

Frequency (MHz)50 Hertz (HZ)

Rated Voltage415 Volt (V)

Energy Consumption.75 Kilowatt-hour ( KWH)

Mifa Systems Pvt. Ltd.

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller18 Years

Weatherproof Loop Power Indicator (Lpi-400 Wp) - Accuracy: Linear : +/-0.1 Percent Of Span ; Square Root : +/-0.2 Percent Of Span %

Price: 5550 INR/Piece

MOQ1 Piece/Pieces

AccuracyLinear : +/-0.1 Percent of span ; Square root : +/-0.2 Percent of span %

Size120(H) x 100(W) x 60(D) in mm

Ambetronics Engineers Pvt. Ltd.

Mumbai

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller16 Years

Orifice Plates - High-Quality Stainless Steel, Differential Pressure Measurement | Durable and Reliable Performance

Product DescriptionKnowing us as a reputed firm, we are engaged in manufacturing, supplying as well as exporting a wide range of Orifice Plates from Vadodara, Gujarat, India. We don't reduce on quality subsequently we obtain crude material from solid source. It is used differential pressure measurement. One can avail

Kabir Instruments And Technology

Vadodara

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller12 Years

Digital Process Controller - Color: Black

Price: 3700 INR/Piece

MOQ10 , Piece/Pieces

UsageIndustrial

Voltage24VDC Volt (v)

Power100-240 Volt (v)

ColorBlack

SizeStandard

Procon Technologies Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller Super Premium

Super Premium15 Years

Super Premium

Super PremiumFlanged Thermowell - Color: Sliver

ConnectionFlange

AccuracyA+-0.5%

MaterialStainless Steel

Operate MethodAutomatic

PressureUp to 5000 PSI

ColorSliver

Precihole Machine Tools Pvt. Ltd.

Bhiwandi

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller9 Years

Belt Way Weighing Controller Accuracy: Wide Range Of Accuracy %

Price Trend: 30000.00 - 200000.00 INR/Set

MOQ1 Ton/Tons

Product TypeAutomatic

Power230 Volt (v)

Voltage230 Volt (v)

ConnectionRs 232

FunctionAutomatic

Esskay Weighing And Automation

Bengaluru

Trusted Seller

Trusted Seller Super Seller

Super Seller6 Years

Servo Controller - Plastic, 204mm x 150mm x 40mm, Gray | 7-Inch Full-Color Touch Panel, 200 kHz Output Frequency, 24V DC, 36 Digital I/O

Price: 26000 INR/Unit

MOQ1 Unit/Units

Operate MethodAutomatic

Accuracy100 %

Weight500 Grams (g)

Dimension (L*W*H)204mm (L) x 150mm (W) x 40mm (D) Millimeter (mm)

ApplicationPlastic, Paper, Fabric Bag making Machine Cut to Length application

Voltage24 Volt (v)

Amess Controls Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller4 Years

Digital RS485 Batch Automation Weight Controller

Price: 10500 INR/Piece

MOQ1 Piece/Pieces

Colorany

ApplicationIndustrial

Product TypeRS485 Batch Automation Weight Controller

TypeAutomatic

Simandhar Technology

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Super Premium

Super Premium11 Years

Super Premium

Super PremiumMethyl Red - Application: Industrial

MOQ50 Kilograms/Kilograms

ColorRed & Yellow

ApplicationIndustrial

UsageLaboratory

Product TypeMethyl Red

FunctionMethyl Red is used for conducting mixed-acid fermentation where it contains peptone, glucose, and phosphate buffer. It also produces desired acid for overcoming buffering capacity of broth that causes decrease in pH results. Further, organisms perform other types of fermentation also cannot overcome buffering capacity of broth.

SizeStandard

Megha International

Mumbai

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Super Premium

Super Premium13 Years

Super Premium

Super PremiumLevel Sensing Controller For Cement Industries - Accuracy: 1 %

Price: 14250.0 INR/Piece

MOQ1 Piece/Pieces

Operate MethodVibrating

ColorOrange And Silver

ApplicationIndustrial

Frequency50/60Hz Hertz (HZ)

Accuracy1 %

MaterialStainless Steel

Industrial PID Controller - Mild Steel, 220 Volt | RS485 & RS232 Communication, Honeywell UDC3300, Dual Set-Points, SCADA Integration, Alarm Outputs

Price Trend: 50000.00 - 500000.00 INR/Pack

MOQ1 Pack/Packs

Power220 Volt (v)

Voltage230 Volt (v)

ApplicationIndustrial, Laboratory

MaterialMild Steel

ColorAny

UsageIndustrial, Laboratory

Didac International

New Delhi

Trusted Seller

Trusted Seller11 Years

Dew Point Analyzer - Accuracy: +/-1 %

Price: 118600.00 INR/Pack

MOQ1 Pack/Packs

UsageIndustrial

Connection1/4 "

Accuracy+/-1 %

Dimension (L*W*H)254 x 180 x 90 Millimeter (mm)

Pressure7 kgf/cm2

Weight0.5 Kilograms (kg)

Applied Techno Engineers Private Limited

Vasai

Trusted Seller

Trusted Seller Super Premium

Super Premium11 Years

Super Premium

Super PremiumAngle And Length Measurement Controller

Price: 1250 INR/Piece

MOQ1 Piece/Pieces

AccuracyA+-0.1 % of full scale (typical)

ConnectionScrew terminals for reliable wiring

FunctionMeasures angle and length simultaneously for precise control applications

SizeStandard compact panel size suitable for industrial control panels

Orchid Technology

Ahmedabad

Trusted Seller

Trusted Seller Super Premium

Super Premium Super Seller

Super Seller8 Years

Super Premium

Super PremiumCable Float Switch - Application: Industrial

MOQ1 Piece/Pieces

ApplicationIndustrial

MaterialPlastic

Product TypeCable Float Switch

Operate MethodAutomatic

ColorBlack Red

Davison Instruments Pvt Ltd

Vasai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

Honeywell Pressuretrol L91b

Product DescriptionWe manufacture, distribute, trade and supply Honeywell Pressuretrol in Ahmedabad, Gujarat, India. Our Honeywell Pressuretrol L91B for Boiler Pressure Control applications. Our Honeywell Pressuretrol L91B is available in various sizes and specifications. These Honeywell Pressuretrol L91B are availabl

Futuristic Technologies

Ahmedabad

Trusted Seller

Trusted Seller Super Premium

Super Premium14 Years

Super Premium

Super PremiumSwimming Pool Digital Controller - Color: White

Price: 250000 INR/Unit

MOQ1 Unit/Units

Voltage220 Volt (v)

Operate MethodAutomatic

MaterialPVC

UsageSwimming Pool

ColorWhite

ShapeRectangular

Potent Water Care Pvt. Ltd.

Delhi

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller8 Years

Fastening Counter Controller

Product DescriptionUryu Fastening Counter Controller Model, UTM-1100, count down the number of bolts or nuts after fastened by the TM-type of Oil-Pulse Tool or impact wrench modified to sense the back pressure from the tool.This remarkable function automatically makes sure of perfect fastening of all the required num

Modern Traders

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller16 Years

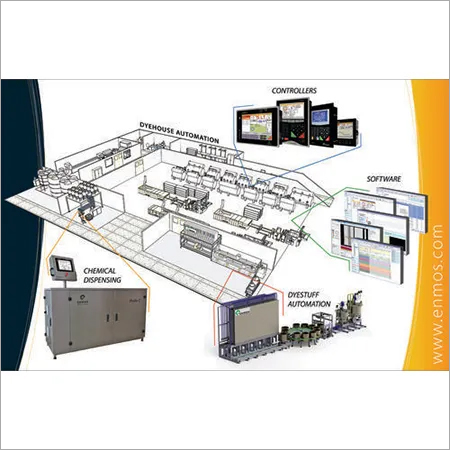

Central Monitoring Management System

Price Trend: 280000.00 - 450000.00 INR/Unit

MOQ1 , Unit/Units

ConnectionSupports LAN/WAN/Wi-Fi; can connect up to 128 devices simultaneously

PressureMonitors and reports gas pressure from 0 to 16 bar

AccuracyHigh fidelity data acquisition with 99% parameter accuracy

FunctionCentral monitoring and management of multiple medical devices and parameters

SizeStandard rack mount format; dimensions 61cm x 41cm x 26cm

R. B Electronic & Engineering Pvt. Ltd.

Chanod

Trusted Seller

Trusted Seller Super Seller

Super Seller15 Years

Ph Indicator - Color: Blue

Price: 12400 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

Operate MethodManual

ColorBlue

MaterialMetal

Product TypePH Indicator

Nuclus Control

Pune

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller15 Years

Pm2.5 Air Quality Sensor - Application: Industrial

Price: 11000.00 INR/Unit

MOQ10 Unit/Units

ApplicationIndustrial

Power5 Volt (v)

Product TypePM2.5 Air Quality Sensor

Voltage12 Volt (v)

Operate Methodbattery

ColorBlack

Airatom Smart Solutions

Delhi

Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

Yudian Make Touch Screen Data Logger Accuracy: 0.2% %

Price: 15000 INR/Number

MOQ1-100 Number

Accuracy0.2% %

Usagetemperature, pressure, humidity, voltage and current data loggers. Multi-input data loggers can measure signals from two or more of these input sources; certain advanced multi-channel models may even be able to sense and record all of the above

ClassificationCE

Product TypePanel Mount

Dimension (L*W*H)135X96mm (WXH) Millimeter (mm)

Weight1 Kilograms (kg)

Micon Automation Systems Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller Super Premium

Super Premium18 Years

Super Premium

Super PremiumLevel Transmitter - Application: Industrial

Price: 32000 INR/Piece

MOQ1 Piece/Pieces

ApplicationIndustrial

ColorSilver

Power SupplyPneumatic

UsageIndustrial

Operate MethodAutomatic

MaterialStainless Steel

G N Engineering Works

Dehradun

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller7 Years

Electronic Control Unit Mlc 03 Generic Drugs

Product DescriptionDisplay Type: Digital, Analog\015\012Display: LED Indication for Mains On,High,Medium & Low\015\012Input Signal: Float Switch Contacts\015\012Mains Power Supply: 230 VAC / 24 VDC\015\012Overall Dimension: 96 X 96 X 65\015\012Unit of Display: LED lights

D. B. Instruments & Controls

Mumbai

Trusted Seller

Trusted Seller Super Premium

Super Premium Premium Seller

Premium Seller12 Years

Super Premium

Super PremiumTemperature Transmitter - ABS Plastic, 50x50x25mm | 4-20mA Output Signal, +/-0.5% Accuracy, 1 Second Response Time, User-Friendly Display

Price Trend: 5500 - 32000 INR/Number

MOQ1 Number

AccuracyA+-0.1% of span

PressureUp to 25 Bar

Connection2-wire or 3-wire Terminal

FunctionTemperature Sensing and Transmission

SizeCompact, Standard Industrial Size

Ishwar Climate Solutions Private Limited

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller10 Years

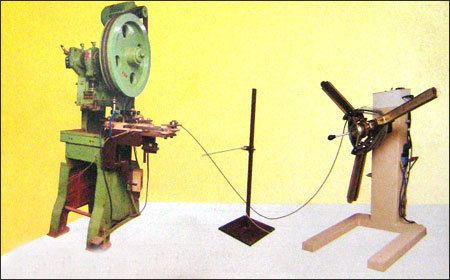

Low Cost Press Feeding Line

Product DescriptionThese high quality Low Cost Press Feeding Line machine are made by using very high quality raw material which ensures hassle free work performance at its user end. Technically advanced design, selection of finest material, combined with strict quality control manufacturing, has resulted in most reli

Press Room Automation And Feed Fixtures Pvt Ltd.

Thane

Trusted Seller

Trusted Seller Super Seller

Super Seller4 Years

Sight Glass - MS, CS (A-105), SS304, SS316 | Sizes 15 to 300 mm, Maximum Pressure 25 kgf/cm2, 360-Degree Visibility for Liquid Flow Monitoring

Price Trend: 5000.00 - 15000.00 INR/Box

MOQ50 Box/Boxes

MaterialM.S, C.S. (AaEUR"105), S.S.304, S.S.316, or MS with Rubber or PP or PVDF or Teflon lined or any other alloy.

UsageChemical, Water

Pressure25 kgf/cm2

ClassificationLevel Indicator

ApplicationChemical Industry

Product TypeSight Glass

Flowtech Measuring Instruments Pvt. Ltd.

Vadodara

Trusted Seller

Trusted Seller Premium Seller

Premium Seller9 Years

Overload Safety Switch

Product DescriptionWe offer our client an excellent quality range of Overload Safety Switch, which are manufactured from high grade quality raw materials. These can be customized as per our precious customers specifications. These are widely known for its durability and quality. Our can be availed at industrial leadin

Silverline Metal Engineering Pvt. Ltd.

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller18 Years

Latest From Process Control Equipment & Instruments

CG Drive SK

By:

Onosef Controls Pvt. Ltd.

Beko Compressed Air Processing

By:

Super Tech Pumps And Equipments

Process Control Equipment & Instruments

By:

Tsa Process Equipments Pvt. Ltd.

Process Control Equipment & Instruments

By:

Alcon Auto Pvt.ltd

Gas Cutter

By:

Excellent Enterprises

Digital Active Power Conditioner

By:

Syscon Enterprises

Flow Controllers

By:

Forbes Marshall Hyderabad Pvt Ltd.

Popular Process Control Equipment & Instruments

Most Popular Process Control Equipment & Instruments

Measurement and regulation of process variables in an industrial setting are the primary goals of the hardware and software that make up process control instruments. Mathematical models of manufacturing processes and systems are the basis for the development of control systems.

Common Process Control Equipment & Instruments

1. Level Control & Monitoring

Instrumentation for measuring and regulating flow tanks, vessels, and compartments can have their contents monitored, detected, and controlled via a control panel or monitor handled by a control engineer. If the current flow rate is too high or too low, the engineer can remotely control an electrical or mechanical actuator to make the necessary changes.

Orifice flow meters, turbine flow meters and Coriolis flow meters are all examples of devices used to regulate pressure in industrial settings.

2. Pressure Control & Monitoring

Using data from pressure sensors, pressure control systems monitor the pressure of a process and provide readings in Bar, KPa, or other applicable units. Mechanical or electrical pressure monitoring and control devices are available. In industries that work with pressured liquids, gases, or solids, they are indispensable equipment for preventing harm to workers and property.

3. Automated control Instrument

In order to better handle hazardous or precise industrial processes, automated control systems are increasingly being implemented. As long as the system is programmed to automatically adjust itself under different settings, a control engineer only has to examine automated control processes on a periodic basis to ensure that they are operating as intended. Because they remove the potential for human error, automated controls improve the consistency of highly repetitive industrial processes.

A catastrophic collapse can be avoided, however, with the help of high-precision equipment. Those in the Oil & Gas, Power Generation, and Air Quality industries can benefit from Makers' top-tier automation and control solutions.

4. Temperature Control & Monitoring Equipment

Instruments for measuring and controlling temperature detect shifts in the temperature of their surrounding environment or of the contents of containers, tanks, pipes, and other apparatus.

Modern Human-Machine Interfaces (HMI) and P&ID systems allow the control and measuring instruments engineer to view temperature readings on a center console or monitor and make changes to one or more processing parameters, or shuttered equipment or the entire plant, to protect critical electrical failure or fire hazards.

5. Supervisory Controls & Data Acquisition

SCADA systems are used in a broad variety of sectors, including but not limited to power production, air purification, wastewater treatment, and manufacturing plants, to coordinate the various tools and systems used to keep tabs on and record data about these activities.

Human-machine interfaces (HMIs) are used by SCADA systems for human interfacing and control, and feedback from sensors and PLCs is relayed to the control engineer.

What Are Process Control Equipment & Instruments?

The purpose of Process Control Equipment & Instruments is to keep an eye on the status of a process parameter, identify when it deviates from the ideal, and then take corrective action.

The ambient temperature, the pressure generated by the cooling water pumping system, and the voltage from the backup generator are all examples of process variables in control systems.

The process variable can only be regulated if its value can be measured and then transformed into a signal that the controller can respond to.

The operator enters or derives from another control calculation the desired value of the process variable, known as the setpoint. The deviation of the process variable from the setpoint serves as the control action's error signal.

Process Control Instruments List

- 1. Water Level Controller

- 2. Temperature Transmitter

- 3. Temperature Scanner Channel USB

- 4. Temperature Scanner

- 5. Synchronizer Card

- 6. Signal Isolators

- 7. Process indicators

- 8. Process Controller

- 9. Load Cell Controller

- 10. Jumbo display Indicators

- 11. Isolator

- 12. Flow Indicator

- 13. Fault Annunciate

- 14. Dual Process Indicator

- 15. Process Controller

- 16. Transducers

- 17. Sensors

- 18. Set Point

- 19. Discrete Controller

- 20. Analog Controller

- 21. Proportional Plus Integral Plus Derivative PID

- 22. Plus Integral Controllers PI

- 23. Control Loops

Working Principle Of Process Control Equipment & Instruments

1. Robustness , preference, Inner Stability, process symbiotic Attitude

Control should make use of the system's inherent dynamics as much as feasible, rather than forcefully influencing process values that are dependent on other variables. Having two people in charge at once always leads to chaos and instability.

Before doing anything else, control engineers should learn as much as they can about the system they are trying to regulate. The constant challenge prevents me from feeling like I've finally mastered something.

When the laws of physics are allowed to interact in a restricted spatial-temporal environment, unexpected phenomena can emerge.

2. Least use of controllers

As the number of controllers in a system increases, so does the chance of instability.

3. Lease use of instrumentation

Control is most tenuous at its instruments. When there are fewer instruments in play, there is less chance of failure or error.

4. Override Control

Multiple controllers and process variables can share responsibility for regulating a single manipulated variable with the help of override control. The same effect can be achieved with only a single controller by exchanging the mistakes that occur in the process variables.

The nonlinearity introduced by the changeover makes it possible that override control will create instability.

Transitional hiccups could be difficult to avoid. It is recommended to utilize a dedicated controller for each process variable unless they all have the same dynamics in the process.

5. Multiple Input control

By adjusting a single process variable, many controlled variables can be kept within their allotted ranges, as is the case with multiple input control.

The boiler steam outlet valve can be calculated using a number of different tuning parameters and temperatures. These include those at the economizer outlet, near the dry-out point, in the first segment of the preheater, at the real and goal stream, at the compression setpoint value and way of measuring, and at other points. I have seen it, so please don't laugh.

If one treats each variable separately, this strategy appears to have merit, especially for mathematical control engineers. When these factors are coupled, as they often are in complex processes, the behavior of the process can become unstable and difficult to predict.

It's important to provide this attractiveness with due consideration and support.

6. Multiple Controlled Input

In contrast to the single-control method, the input from several sources requires more attention. Many feedback loops and manipulated variables are all driven by the same controlled variable.

Maintaining the intended superheat level in a once-through boiler could be accomplished by adjusting the inbound water flow for slow modification of the water stock and dry-out point as well as the generator's output for quick and easy way of the temperature within the expected range.

Make sure there is enough room between the two operational domains, and figure out the dynamics to avoid resonances.

7. Model-based or Feed forward Control

By its very nature, model-based/feedforward control is robust and quick to recover from shocks. It prevents a negative impact from a disturbance on the process variables by making adjustments in advance.

Obviously, this is effective only if the model is stable and reliable enough to have a net beneficial effect on the control performance in general. Negligible control is guaranteed if these prerequisites are not met.

8. Negentropic, Lean Development

The physical universe has a built-in propensity toward increasing entropy over time. The concept of entropy is associated with the future, rather than the past. Notwithstanding this fatal fate, the world continues to advance thanks to the negentropic, the reverse-entropy force of correctly handled knowledge, one of the fundamental features of life.

Even when following best practices, control development often devolves into chaos as fixes pile up without ever getting to the root of the problems and as unused code remains in place.

The growth in code size over time is a quantifiable indicator of control's improving status. After all functionality has been delivered and commissioning and optimization have begun, the code volume should decline or at worst remain stable.

After an upgrade, either a current feature will be simplified, or a new feature of equal or greater complexity will replace an existing one.

Conclusion

Producing a high-quality product over and over requires stringent process control. Multiple materials, ranging from chemicals to physical objects, are used in any procedure. Automatic pipeline and product throughput adjustments made possible by process controls help maintain pipeline dependability, safety, and consistent oil or gas flow. Refineries utilize process controls to guarantee the security of workers, the quality of output, and the continuity of operations.

FAQs: Process Control Equipment & Instruments

Q. What are process control instruments?

Ans. Instrumentation for process control focuses on the monitoring and regulation of processes in an industrial setting. Scientific models of industrial systems and processes form the basis for control system design.

Q. What are the common instruments needed in the process control industry?

Ans. Here are some common instruments:

- Supervisory Control & Data Acquisition

- Pressure Control & Monitoring

- Temperature Control & Monitoring

- Level Control & Monitoring

Q. What are examples of process control instruments?

Ans. Some examples of process Control instruments are:

- Cooling Element with a Room

- Nuclear Power Plant Control Rod

- Desalination

- Cooking of Meat Products

Q. What is the cost of process control equipment & instruments?

Ans. The cost of process Control Equipment & instrument is between Rs 5,000- RS 5 lakhs.

Manufacturers & Suppliers of Process Control Equipment & Instruments

Company Name | Member Since |

|---|---|

Mifa Systems Pvt. Ltd. Ahmedabad, India | 18 Years |

Micon Automation Systems Pvt. Ltd. Ahmedabad, India | 18 Years |

Silverline Metal Engineering Pvt. Ltd. Mumbai, India | 18 Years |

Ambetronics Engineers Pvt. Ltd. Mumbai, India | 16 Years |

Modern Traders Mumbai, India | 16 Years |

Procon Technologies Pvt. Ltd. Ahmedabad, India | 15 Years |

R. B Electronic & Engineering Pvt. Ltd. Chanod, India | 15 Years |

Nuclus Control Pune, India | 15 Years |

Futuristic Technologies Ahmedabad, India | 14 Years |

Megha International Mumbai, India | 13 Years |

Popular Products