Deep Drawing Part And Oem Mould

Price:

Get Latest Price

In Stock

Product Specifications

| Mold Material | Mold steel |

| Profile Tolerance | 0.005MM |

| Surface Treatment | Mirro polished |

| Transport Method | Air or sea |

| Delivery Time | 10-15 days |

| Equipment | CNC lathe |

| Quality Control | 100% inspection |

| Features | Oem Stretching, Precision Mold, Customized Type, Mass Production |

Product Overview

Key Features

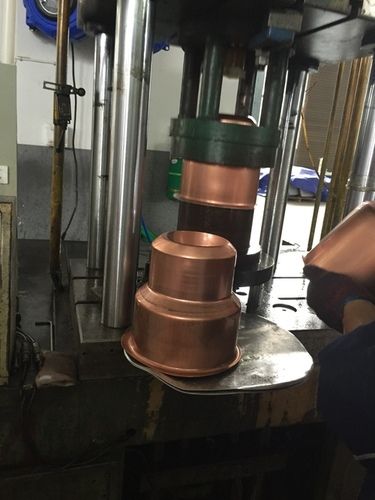

Tangsheng skills supply customers metal mold and metal parts, mainly material is aluminum, stainless steel, steel, copper/brass,

Product name : metal stretching and stamping mold

Product function : precision mold and production for mass metal parts production

Material : mold steel(S136, SKD61, SKH-51, HPM38, STAVAX, 1.2343, 1.2344, 1.2767, 8407, etc)

Profile tolerance : can beA A 0.005MM

Surface treatment : Mirro polished,Technical Polished,Mold Tech texture, Nitriding ,plating ,VDI texture etc

Transport method : below 500 lb by air,above 500 lb by sea.

Delivery time : 10-15 days after payment.

Production type : OEM & ODM Manufacturer

Customized type : non-standard product according to the 2D/3D drawing from clients,standard product conform DEM,HASCO,Misumi,DIN,international standard

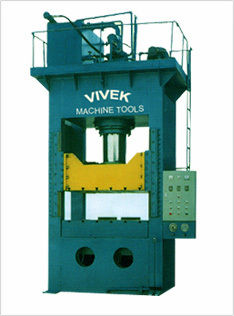

Equipment : CNC lathe,Wire cutting, EDM, Stamping punching machines, CNC machining, Automatic lathe, Grinder, Drilling Milling Machines,Profile projector,height gauge,three dimensional measuring instrament,tool makers microscope,height gauge,thickness meters,laser mark machine etc.

Quality control : 100% inspection before shipment.

Trade term : EX WORK,FAC,FOB,CIF,CFR..

Payment method : T/T,L/C,D/A,D/P,Western Union,Credit card,etc...

MOQ : 2PCs,Depending on detailed orders. Accept order for small batches.

Sample : can be provide a trial sample.

China deep draw and punching mould

There are more cookware parts made by deep draw, stretching way, like: pan mould, frying-pan deep draw mould, stew-pan mould, wok, pressure-cooker, electric rice cooker, aluminium ware, metal Spoon, aluminum kitchen utilities, metal vacuum and single cup, bowl, casserole mould, deep fry pan, double boiler mould, egg pan, stainless steel cover, egg pan, egg poacer, fish pan fish pot, fondue, fry pan, griddle mould, grill pan deep draw mould, some handle, different kinds of hot pot, kettle, knob, milk pan, mixing bowl, oval roaster mould, paella pan, pressure cooer, metal cover, lid many many are made from deep draw and stretching, etc.

As china stretching and punching supplier, we do OEM stretching mould and parts for customers, all done strictly according drawing or sample,

1. Basic Information

Mold type: all tyes of produts stretching mould

Mould base material: SKD12. H13, national mould steel standard, etc

Mould design: 3D/2D drawings

Design days: 1-3days

Mould life: 300,000-500,00 pieces (usual mold, precision mold could share more)

Part material: aluminum, stainless steel, steel, copper/brass, carbon steel, etc.

Surface coating: anodize, oxidation, power coating, painting, etc

2. Application

Communication/Electronic/Auto parts/kitchen products/Medical device/equipment shell/outdoor ad/food container/ and so on.

3. Customers assistance for quotation

1) 2D/3D Design drawings preferred

2) If there is no drawing, please advise the dimension/photos with dimension

3) Material, surface coating

4) Mould life you want

Q&A about stretching mould

Q. I have an idea for a new product, but don't know if it can be manufactured. Can you help?

A: Thanks for we have professional engineers team, they could help you evaluate technical feasibility of your idea or design to help making project goes better.

Q. My components have already been developed on CAD. Can you use the drawings?

A.DWG, DXF, IGES, Solidworks and Rhino files are with exact structure and dimension, especially some details, so those files are prefered and good to make exact quotes, if with such files, pls support.

Q. Can I test my idea/component before committing to mould tool manufacture?

A. Yes, we can use CAD drawings to make models for design and functional evaluations.

Company Details

Focusing on a customer-centric approach, Ningbo Tangsheng Precision Ltd has a pan-India presence and caters to a huge consumer base throughout the country. Buy Power Press in bulk from Ningbo Tangsheng Precision Ltd at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

45

Establishment

2014

Working Days

Monday To Saturday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Ningbo, Zhejiang

Ms Tina

Address

Shajiadian Industrial Zone, Yinzhou District, Ningbo, Zhejiang, 321300, China

deep drawing press in Ningbo

Report incorrect details