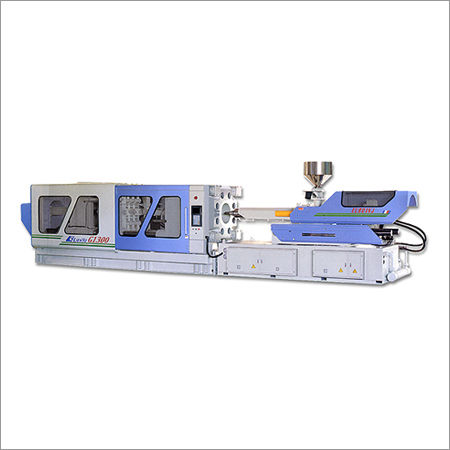

D-series Injection Molding Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Screw Diameter | 28-60 Mm |

| L/D Ratio | 17.8-22.8 |

| Swept Volume | 98-735 Cc |

| Max Shotweight | 88-661 G |

| Max Injectionpressure | 1327-2321 Bar |

| Max Lockingforce | 75-255 Tonne |

| Machinedimensions | Variable |

| Features | Compact Design, High Performance, Cost-Effective, High Speed, Long Lifespan, Perfect Alignment, High Locking Force, Safe Operation |

Product Overview

Key Features

D-Series Injection Molding Machine

Compact

Construction With High Performance & Cost Effectiveness

We have benefited from

Sino-British co-operation with " A&A Industrial Ltd "

since 1988. During this period, we introduced our UF-II Serieswhich

was well received by our customers worldwide.Using the experience of

both ourselves and our customers, we have developed the "D

Series" to give a machine with a smaller footprint and more

compact hydraulic & electronic sections.

We believe the newly

developed and upgraded EURO INJ "D Series" will satisfy the

needs of discerning end users whoseek quality and efficiency.

Injection manifold mounted

close to the injection unit giving high speed response.

By employing Computer

Aided Design and Finite Stress Analysis the life of machine is

guaranteed. The box construction of the moving platen results in a

very long guidance length of the tie bars.so ensuring perfect

alignment of the mould elements.The powerful balanced five point

toggle system applies the full locking force to the box sectioned

moving platen which transmits the force to the mould without

deflection either during clamp application or injection. To satisfy

the most stringent of safety requirements, the machines are equipped

as standard with three interlocks toprevent the mould closing without

the guard being closed, l.e:Electrical Hydraulic Mechanical It should

be noted that our newly designed mechanical scotch bar is located

within the footprint of the actual locking unit and is the subject of

a patent application.

@ | MODEL | Unit | D.75 | D.95 | D.125 | D.155 | D.205 | D.255 | ||||||||||||

INJECTION | Screw Diameter | mm | 28 | 32 | 36 | 32 | 36 | 40 | 36 | 40 | 45 | 40 | 45 | 50 | 45 | 50 | 55 | 50 | 55 | 60 |

Screw L/D Ratio | L/D | 22.8 | 20 | 17.8 | 22.5 | 20 | 18 | 22.2 | 20 | 17.77 | 22.5 | 20 | 18 | 22.2 | 20 | 18.1 | 22 | 20 | 18.3 | |

Swept Volume | cc | 98 | 128 | 162 | 144 | 183 | 226 | 203 | 251 | 318 | 276 | 349 | 431 | 381 | 471 | 570 | 510 | 617 | 735 | |

Max shot | g | 88 | 115 | 146 | 130 | 164 | 203 | 183 | 226 | 286 | 248 | 314 | 388 | 343 | 424 | 513 | 459 | 555 | 661 | |

oz | 3.1 | 4.0 | 5.1 | 4.5 | 5.8 | 7. | 6.4 | 7.9 | 10 | 8.7 | 11.1 | 13.7 | 12 | 14.9 | 18 | 16.2 | 19.6 | 23.3 | ||

Max shot | bar | 2321 | 1777 | 1404 | 2180 | 1722 | 1395 | 2074 | 1680 | 1327 | 2104 | 1662 | 1346 | 2125 | 1722 | 1423 | 2046 | 1691 | 1421 | |

Max Injection | g/sec | 49 | 65 | 82 | 67 | 85 | 105 | 84 | 103 | 131 | 106 | 134 | 166 | 131 | 162 | 196 | 165 | 199 | 237 | |

Screw Stroke | mm | 160 | 180 | 200 | 220 | 240 | 260 | |||||||||||||

LOCKING | Max Locking | tonne | 75 | 95 | 125 | 155 | 205 | 255 | ||||||||||||

Max Opening | mm | 270 | 320 | 355 | 390 | 430 | 475 | |||||||||||||

Min Mould | mm | 100 | 130 | 130 | 150 | 150 | 150 | |||||||||||||

Max Mould | mm | 360 | 400 | 430 | 460 | 525 | 650 | |||||||||||||

Max Dayllght | mm | 630 | 720 | 785 | 850 | 955 | 1125 | |||||||||||||

Space between | mm | 320x320 | 360x360 | 410x410 | 430x430 | 470x470 | 510x510 | |||||||||||||

Diameter of | mm | 55 | 60 | 70 | 80 | 90 | 100 | |||||||||||||

Max Ejector | tonne | 2.74 | 2.74 | 3.32 | 3.95 | 3.95 | 7.03 | |||||||||||||

Max Ejecto | mm | 80 | 90 | 110 | 130 | 140 | 150 | |||||||||||||

GENERAL | Pump Drive | kw(HP) | 7.5(10) | 11(15) | 15(20) | 18.5(25) | 22(30) | 30(40) | ||||||||||||

Hydraulic | bar | 140 | 140 | 140 | 140 | 140 | 140 | |||||||||||||

Heating Capacity | kw | 4.0 | 4.6 | 6.5 | 7 | 8 | 10 | |||||||||||||

Number of | qty | 3+N | 3+N | 3+N | 3+N | 3+N | 3+N | |||||||||||||

Oil Filling | liter | 220 | 300 | 265 | 280 | 330 | 450 | |||||||||||||

Machine | m | 3.8x1.05x1.5 | 4x1.1x1.6 | 4.6x1.2x1.68 | 5.4x1.25x1.8 | 5.8x1.3x1.9 | 6.2x1.35x2.0 | |||||||||||||

Machine | kgs | 3,500 | 4,300 | 5,600 | 6,500 | 7,500 | 10,000 | |||||||||||||

INJECTION

WEIGHT=CALCULATED INJECTION VOLUME x GRAVITY SPECIFIC x 85%

We Reserve The Right To

Amend The Above Figure Without Prior Notice.

Company Details

Focusing on a customer-centric approach, LIEN YU MACHINERY CO., LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Machineries in bulk from LIEN YU MACHINERY CO., LTD. at Trade India quality-assured products.

Business Type

Importer, Trading Company

Employee Count

80

Establishment

1985

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Taoyuan, Taoyuan

Mr. Rajesh Rana

Address

No.60 Tay Yii 12 Street, Tu Kou Village, Jen The Hsiang, Tainan Hsien, Taoyuan, Taoyuan, 717, Taiwan

used injection molding machine in Taoyuan

Report incorrect details