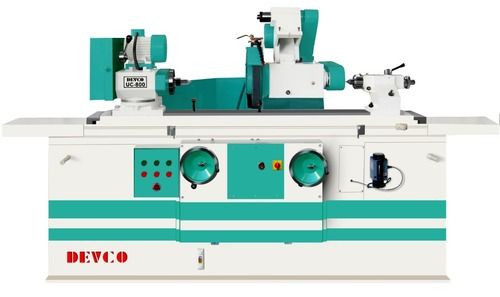

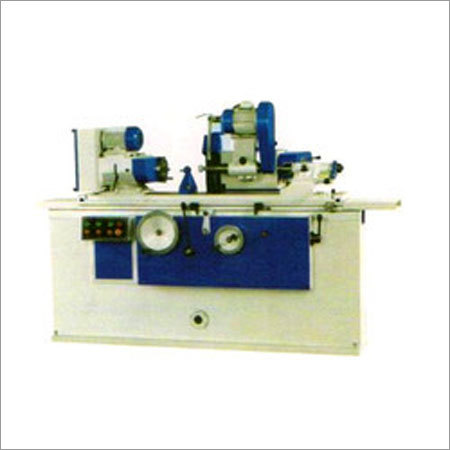

Cylindrical Grinding Machine - High Grade Alloy Cast Iron Body, Precision Hand Scraped V And Flat Ways, Swiveling Table For Taper Grinding, Detachable Workhead And Tailstock

Price:

Get Latest Price

In Stock

Product Specifications

| Dimensions | 1800 X 75 Mm |

| Power | 1.5 Hp |

| Material | Ms-Fabricated |

| Area Required | 2X2 & 7X7 Feet |

| Grinding Wheels | Multiple |

| Features | Adjustable Angle, Heavy Duty, High Quality, Customizable, Industrial Price, Efficient Grinding, Durable Design |

Product Overview

Key Features

Table: It is composed of two parts. The lower part is called "Slide" and upper part "Table". "TURCITE - B" is lined on table ways and as well as on slide ways. The slide moves on V and flat ways of bed provided for which ensure very smooth longitudinal table movement. The upper table can swiveled for external and internal grinding jobs. with fine setting arrangement.

WORKHEAD & TAILSTOCK

Both are detachable and adjustable when required. Work head alloy steel spindle has been made for revolving as well as stationery centers. The spindle is fitted with phosphorous bronze taper bushes inside the work head and can be swiveled up to 90 towards grinding wheel and 30 towards operator for taper and conical grinding. The drive to work head spindle is given by an electric motor through V-belts. The tailstock spindle runs in a honed bore and is spring loaded for quick release. Morse tapers are arranged for dead centers to be fitted in work head spindle and tailstock spindle noses.

WHEELHEAD

Designed to ensure maximum rigidity and smooth operation. The spindle is fitted with white metal taper bushes. The Grinding wheel is fitted on a taper nose mounted in wheel-flange, arranged to balance for vibration free operation.

Company Details

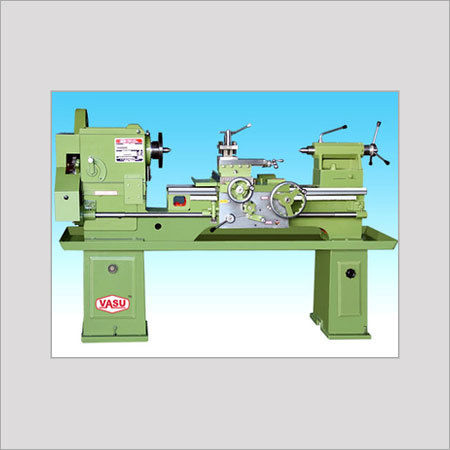

ATUL Machine Tools is a Machine Tool manufacturing company based in Rajkot focus products being Surface Grinding Machines, Cylindrical Grinding Machines, Conventional Lathe & SPMs. Incorporated in 1989, ATUL Machine Tools has set-up a modern manufacturing/assembly/ testing facility to constantly work on bringing out better solutions in Grinding & Turning processes. The company's main office is situated in Rajkot city while the Company's workshop is located in highly grown industrial zone Lodhika G.I.D.C. of Rajkot district which is India's well known city for tool and machinery industry. The company workshop is spreaded out in 10000+ sq. ft. area. The workshop is well equipped with various precision mother machines and latest inspection and testing equipments & methods as per IS standards. The company is ready to undertake any challenge from design concepts to the manufacturing, erection and commissioning of any type of S. P. M. Machines.

Business Type

Exporter, Manufacturer, Supplier, Trading Company

Employee Count

10

Establishment

1994

Working Days

Thursday To Tuesday

GST NO

24ACPPM0937M1Z7

Payment Mode

Cash in Advance (CID)

Certification

ISO 9001:2000 ,L.E.A.N

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24ACPPM0937M1Z7

Rajkot, Gujarat

M/s Atul Machine Tools

Members since

17 Years

Address

Gate No.2, Almighty Gate, Plot No. P -103, Lodhika G.I.D.C, Kalawad Road, Metoda, Rajkot, Gujarat, 360021, India

hydraulic cylindrical grinding machine in Rajkot

Report incorrect details