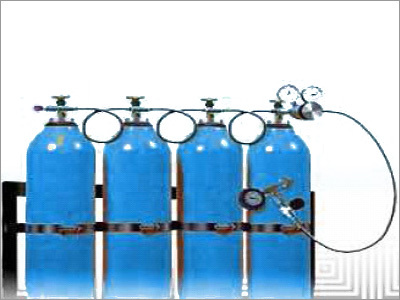

Cylinder Testing Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Customizable |

| Pressure Range | Medium |

| Gauges | Dual |

| Valves | Multiple |

| Tubing | Stainless Steel |

| Manometer | Vertical |

| Features | Accurate Testing, Durable Design, Easy Operation, Reliable Results, Efficient Process, High Precision, Safe Operation |

Product Overview

Key Features

Cylinder Testing Machine

Process used in Oxygen Nitrogen plants -Medium Pressure

Construction Materials for Air separation plants:

The materials used in an air separation plant are exposed to wide range of temperatures, pressures, and purities during operation. Materials are selected that are compatible with the expected condition including normal operation, startup, shutdown, and process upsets.

For the oxygen system to operate safely, all parts of the system should be reviewed for compatibility with oxygen under all conditions they will encounter. The system is designed to prevent oxygen combustion by:

- Selecting the optimum cryogenic grade material.

- Operating within the designed pressure, temperature, and flow limits; and

- Obtaining proper cleanliness.

BOSCHI 5 step process

PROCESS DESCRIPTION:

STEP 1 - Air Compression

In the first stage air is compressed at a low pressure of 5-7 bar (Gas plants) to 10 Bar (liquid plants). Air can be compressed at such low pressure by trouble free rotary compressor (Screw / Centrifugal Type advanced technology is employed in lieu of old bulky piston reciprocating compressor).

STEP 2 - Air Pre-Cooling

The second stage of the process uses a low pressure refrigerant (R-407A as per CE regulations) for pre-cooling the processed air to temperature around 12 deg c before it enters the purifier.

STEP 3 - Purification of Air by Purifier

The air enters a purifier consisting of twin Molecular Sieve driers, working alternatively. The Molecular Sieves remove the Carbon dioxide & moisture from the process air before the air enters Air Separation Unit.

STEP 4 - Separation of Liquid Air into Oxygen and Nitrogen in Air Separation Column

Oil free, moisture free and Carbon Dioxide free air enters into low pressure plate fin type Heat exchanger where the air is cooled below sub zero temperatures by air expansion process in the turbo expander. Due to the excellent thermal efficiency we can achieve a temperature difference delta t as low as 2 deg c at the warm end of these exchangers.

The air has to be cooled to sub zero temperatures for liquification & the cryogenic refrigeration & the cooling is provided by highly efficient turbo expander, which cools the air to temperature almost below -165 to-170 deg C. Air gets liquefied when it enters the air separation column & gets separated into oxygen & nitrogen by the process of rectification.

Oxygen is available in gas or liquid form (as per requirement) at the outlet of the ASU at a purity of 99.6%. Nitrogen is also available at the outlet as a second product at purity of 99.99% upto 3ppm simultaneously without loss of oxygen product (or as specified).

STEP 5 - Product storage

For Gas: The final product in the form compressed Oxygen/Nitrogen goes to the high pressure oxygen cylinders at 1 50 bar or upto higher as required. OR, for pipeline supply or captive consumption. For Liquid: Liquid Oxygen / Nitrogen to fill in cryogenic liquid tanks.

Oxygen Filling Pump

Category 1 in medium pressure oxygen nitrogen plants-Cylinder Filling Oxygen Nitrogen Plants

Range: 20m3/hr to 1000m3/hr

With leakproof stainless steel column and skid mounted version for high purity medical and industrial oxygen.

Description: UB series oxygen/nitrogen plants are used for filling high pressure Oxygen/nitrogen gas in cylinders/bottles by liquid oxygen pump ( oil free & water free) for industrial & medical applications .For filling liquid oxygen & liquid nitrogen additional liquid tapping facility is available.

- Small Capacity(20-50m3/hours)

- Medium Capacity(60-150)

- Large Capacity(200- 1000)

| Name of the Models | UB - 20 | UB - 30 | UB - 50 | UB - 80 | UB - 100 | UB - 150 | UB - 200 | UB - 300 | UB - 400 | UB - 500 | UB -1000 |

| Capacities (M3/Hr) | 20 | 30 | 50 | 80 | 100 | 150 | 200 | 300 | 400 | 500 | 1000 |

| No. of Cylinders in a Day | 80 | 120 | 200 | 300 | 400 | 600 | 800 | 1200 | 1600 | 2000 | 4000 |

Filling of oxygen by liquid oxygen pumps, liquid nitrogen pump is optional.

We manufacture oxygen plants and nitrogen plants as per the latest technology & design of the Company ING. L. & A., BOSCHI, ITALY. This technology has been proven all over the world for its working efficiency & trouble free operation. The AIR SEPARATION COLUMN of BOSCHI has state of the art distillation trays, multipass exchangers condenser to get a high yield of Oxygen by separation of Liquid Air, which results in very low pressure & low power consumption.

Salient Features

- Leak Proof Stainless Steel Boschi Air Separation Column

- Skid Mounted Version available

- Oversize Molecular Sieve Dryer

- Quick start for fast cooling

- Very simple to operate

- No raw material is required

- Trouble free operation for years (German design)

- Easy availability of spare parts

- Low power consumption

- Production of oxygen & nitrogen simultaneously without use of bulky gas holders.

- Latest molecular sieve technology without recurring cost of chemicals

- Latest BOSCHI-ITALY oxygen plant design

- Very compact & sturdy oxygen and nitrogen plants

- Low working pressure of oxygen gas plants

- Very low maintenance for producing oxygen gas

- Raw material -Free Atmosphere Air for producing oxygen/nitrogen gas/liquid

- Latest molecular Sieve absorption without receiving cost of chemicals.

- Liquid Oxygen / Nitrogen pump with internal gas vaporizer for filling of oxygen gas in cylinders.

- Hydraulic type Expansion Engine for oxygen/nitrogen plants

- Highly efficient BOSCHI-TYPE trays for maximum recovery of oxygen

- Highly efficient Heat-exchanger for recovery of waste cold energy to reduce operating cost.

- The oxygen plant is supplied complete as per standard scope of supply.

Main Equipment:

| SR. NO. | QTY | ITEM | DESCRIPTION |

| 1. | One | SUCTION FILTER | High efficiency filter supplied with the compressor |

| 2. | One | AIR COMPRESSOR OF OXYGEN/NITROGEN PLANTS | This is 4-multistage heavy duty water cooled air compressor with fly wheel inter cooler, foundation bolts, motor pulley, motor, v belt, guard and slide rails and air filter. This is used to compress atmospheric air complete with ABB Motor and Starter. |

| 3. | One | PROCESS SKIDOF OXYGEN/NITROGEN PLANTSAll the above equipments are neatly mounted on skid /platform complete with interconnecting piping and ready for installation of Oxygen Plant is optional. | This consists of the following items for Air Separation Plant |

| 4. | One | Expansion Engine Of Oxygen/Nitrogen Plants | Complete with motor/starter/ starter shall be of Siemens /ABB/ with hydraulic valve control, bursting disc for safety, hydraulically operated high efficient engine with ball type of valves stainless steel liner vertical type of German design. |

| 5 | One | Air Separation Unit (COLD Box)Of Oxygen/Nitrogen Plants | (Air separation column -cold box) consists of outlet steel casing, main heat exchanger, liquifier, bottom column, top column, condenser, sub cooler, liquid oxygen and nitrogen filter. Cooling pipe line, insulation material, digital electronic temperature indicator and scanner, PT 100 sensor, DP gauge manometer, Expansion valve with long stem type with pointer And index & wheel (Stainless Steel column argon welded to meet European specifications can be supplied) |

| 6. | Set | High Pressure Filling Manifold Of Oxygen/Nitrogen Plants | For filling high-pressure Oxygen gas to Cylinders. It consists of main High Pressure Isolation Valve and Pigtail connection with individual Valve with Pressure Gauge and Safety Relief Valve. |

| 7 | One | Liquid Oxygen Pump Of Oxygen/Nitrogen Plants | Horizontal single acting pump with Piston, Piston Rings, Safety Devices, Non-Return Valves with Stainless Steel head for long life, Motor and Starter with Pulley, V-Belts, Belt Guard, Inter Connecting Pipes with A. S. U. Suitable for filling Oxygen. |

| 8 | One | Cooling Tower Of Oxygen/Nitrogen Plants | Induced Draft-Rotary Sprinkler type with Aluminium Casting Fan, FRP Body with suitable Electric Motor for maintaining the circulating water temperature between the Hot well and Cold well for optimum performance of the Plant. Complete in all respects. |

| 9 | One | Electricalpanelof Oxygen/ Nitrogen Plants | Electrical Panel for supply of electricity to individual motors. It has a bank of on/off switches and fuses. This enables the Operator to control all the Motors from one point. |

| 10 | One | Water Softenerof Oxygen/Nitrogen Plants | Made of HDPE having single mutiport valve for different plant valve for different operations. Used to remove hardness of the water and to avoid scaling in Air Compressor Cylinder jacket and water line. Nacl/Regeneration. With min/max. working pressure in 2.0/4.0 kgs/cm2. Complete in all respect |

| Model | UB-20 | UB-30 | UB-50 | UB-80 | UB-100 | UB-150 | UB-200 | UB-300 | UB-400 | UB-500 |

| Capacity (M3/Hr) | 20 | 30 | 50 | 80 | 100 | 150 | 200 | 300 | 400 | 500 |

| No Of Cylinders/Day | 80 | 120 | 200 | 300 | 400 | 600 | 800 | 1200 | 1600 | 2000 |

| Area Required(Axb)M | 6 x 8 | 6 x 10 | 8 x 12 | 12 x 15 | 14 x 15 | 14 x 15 | 14 x 15 | 15 x 16 | 15 x 18 | 18 x 20 |

Company Details

Focusing on a customer-centric approach, UNIVERSAL INDUSTRIAL PLANTS MFG. CO. PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Industrial Gas Plants in bulk from UNIVERSAL INDUSTRIAL PLANTS MFG. CO. PVT. LTD. at Trade India quality-assured products.

Business Type

Distributor, Supplier, Trading Company

Employee Count

50

Establishment

1985

Working Days

Monday To Sunday

GST NO

08AAACU7501K1Z9

Related Products

More Product From This seller

Seller Details

GST - 08AAACU7501K1Z9

New Delhi, Delhi

Manager

Mr Sk Agarwal

Address

R-19, Hauz Khas Enclave, New Delhi, Delhi, 110016, India

Report incorrect details